COOLERS

The amount of moisture that air can hold is inversely proportional to the pressure of the air. As the pressure of the air increases, the amount of moisture that air can hold decreases. The amount of moisture air can hold is also proportional to the temperature of the air. As the temperature of the air decreases, the amount of moisture it can hold decreases. The pressure change of compressed air is larger than the temperature change of the com pressed air. This causes the moisture in the air to condense out of the compressed air. The moisture in compressed air systems can cause serious damage. The condensed moisture could cause corrosion, water hammers, and freeze damage. Therefore, it is important to avoid moisture in compressed-air systems. Coolers are used to address this problem.

Coolers are frequently used on the discharge of a compressor. These are called after coolers, and their purpose is to remove the heat generated during the compression of the air. The decrease in temperature promotes the condensation of any moisture present in the compressed air. This moisture is collected in condensate traps that are either automatically or manually drained.

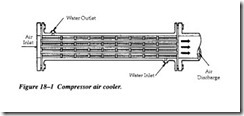

If the compressor is multistage, there may be an intercooler, which is located after the first-stage discharge and second-stage suction. The principle of the intercooler is the same as the principle of the aftercoolers, and the result is drier, cooler compressed air. The structure of the individual cooler depends on the pressure and volume of the air it cools. Figure 18-1 illustrates a typical compressor air cooler.

The combination of drier compressed air (which helps prevent corrosion) and cooler compressed air (which allows more air to be compressed for a set volume) is the rea son air coolers are worth the investment.