Separation devices

An assessment of the magnitude of a potential dust problem can be made by examining the bulk material to be handled, paying special attention to the fines content of the material. When making a decision about the type of gas–solid separation device to be used in a pneumatic conveying plant for a particular material, it is clearly more important to know the particle size distribution of the bulk material after conveying than at the feed point. Tests are available to determine the ‘dustability’ of a material; that is, the propensity of particles from within the bulk to become airborne when subjected to external forces.

Gravity settling chambers

The simplest type of equipment for separating solid material from a gas stream is the gravity settling chamber in which the velocity of the gas–solid stream is reduced, and the residence time increased, so that the particles fall out of suspension under the influence of gravity. Such a device is shown in Figure 7.2.

Collecting efficiency

The rate at which solid particles settle in air, and hence the efficiency of the process of separation, is primarily dependent upon the mass of the particles. This effectively means a combination of their size and density. In general, settling chambers on their own would only be used for disengaging bulk solids of relatively large particle size. Typically this would mean particles greater than about 150 J..m, but this obviously depends also upon the shape and density of the particles; hence the value of tests and experience gained. For particles larger than about 300 J..m, a collecting efficiency in excess of 95 per cent should be possible.

To improve the collecting efficiency of the basic gravity settling chamber when working with materials of low density, or of a fibrous nature, a mesh separating screen could be fitted at an angle across the gas flow, as shown in Figure 7.2b. The screen should be provided with a rapping mechanism to shake collected particles free on a regular basis. Although the gravity settling chamber is basically a very simple device, care should be taken to ensure that its design allows, as far as possible, a uniform distribution of the gas as it enters and leaves.

Within the settling chamber the gas velocity should generally be less than about 3 m/s if excessive re-entrainment of collected particles is to be avoided. Where a material consists essentially of coarse particles, but also has some dust content, it may be satisfactory to use a settling chamber with the gas vented through a suitable fabric filter.

This technique is commonly used for disengaging coarse material after conveying pneumatically in either a positive or a negative pressure system. In this arrangement of filter–receiver it is important that the filter is correctly sized to prevent over load- ing, and that an adequate cleaning routine is followed.

Cyclone separators

In pneumatic conveying plants handling medium to fine particulate material, the gas–solid separator is often a cyclone-receiver. This may be combined with a fabric filter unit if the bulk material is dusty. Like the simple gravity separating chamber, the cyclone separator is dependent upon the mass of the particles for its operation. The forces that disengage the solid particles from the conveying gas, however, are developed by imparting a spinning motion to the incoming stream so that the particles migrate out- wards and downwards under the influence of centrifugal and gravitational effects.

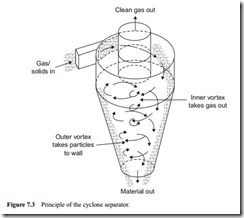

Reverse flow type

The commonest form of cyclone is the so-called ‘reverse flow’ type, illustrated in Figure 7.3, in which the rotation of the gas is effected by introducing it tangentially to the cylindrical upper part of the device, thereby creating a spiral flow downwards. This spiral

continues down the outside of the unit until it reaches a point, near to the base of the cone, where it reverses its direction of flow. The solid particles are then collected from the outlet at the base of the conical lower part while the cleaned gas flows in the opposite direction through the top outlet.

Alternative designs of cyclone separator that have been proposed include the ‘straight-through’ type, in which the rotation of the gas–solids stream is imparted by fixed vanes mounted in a circular duct. The cleaned gas leaves through a concentric inner duct while the solid particles are extracted through an annular space between the inner and outer ducts.

Collecting efficiency

The size of particles that can be separated in a cyclone, and the collecting efficiency, depend principally upon the difference in density of the solid particles and the conveying gas, the solids concentration, the inlet gas velocity and the dimensions (notably the diameter) of the cyclone itself. Increasing the entry velocity or decreasing the cylinder diameter should normally result in an increase in the collecting efficiency of finer particles, but the practical lower limit on particle size is likely to be around 10 J..m.

It should be noted that decreasing the cylinder diameter will reduce the gas–solids throughput, and consequently more cyclones will be needed for a given application, and at greater cost. Also, operating at a higher inlet gas velocity (up to a maximum of about 30 m/s) may cause difficulties when the conveyed particles are abrasive or friable. In contrast, operation at higher solids concentrations may be advantageous, as finer particles tend to be trapped and swept out by larger particles, resulting in an improved collecting efficiency.

Typical dimensions

The dimensions of a cyclone designed for optimum performance will therefore depend on its actual application, that is, on the nature of the solid material to be separated and the separation efficiency required. Typically the proportions would be as shown in Figure 7.4. It is general practice to avoid extremely large diameter cyclones and provide extra capacity by means of smaller units connected in parallel. Most commercial units, therefore, are typically less than 3 m in diameter.

For high collecting efficiency the shape of the cyclone would be modified by decreasing the cross-sectional area of the gas–solid inlet and the gas outlet, and reducing the depth to which the gas outlet duct extends into the cyclone cylinder. Also, for high efficiency, a cyclone of smaller diameter would be selected. Thus, while it would be usual to select a single cyclone of suitable capacity for a given application, multiple parallel units would give better collecting efficiency for fine particles. Two of more units in series might be preferable, where the material to be collected has a wide particle size range.

Many attempts have been made to develop theoretical expressions for the prediction of collecting efficiency, based on the dimensions of the cyclone and on the properties of the gas and solid material to be separated. None has really proved to be satisfactory and reliance must be placed on experimental data for cyclone performance.

The data is normally presented in the form of a plot of collecting efficiency against particle size for cyclones tested with some ‘standard’ material. Such a plot for two possible design extremes is presented in Figure 7.5 [1]. One plot is for a high efficiency cyclone, and the other is for a low efficiency cyclone having a high throughput capability. Possibly two or more of the high efficiency cyclones would be needed to meet the flow rate capability of the low efficiency cyclone.

Filters

The fabric filter is now the ‘industry standard’ for gas–solid separation duties in pneumatic conveying systems. This is particularly the case where there is an element of dust in the conveyed material. Considerable development has taken place over recent years, with particular improvements in fabrics. In order to appreciate the principles on which filter units are designed or selected it is helpful to understand the manner in which they operate.

Filtration mechanisms

There are two fundamental mechanisms by which particles can be removed from a stream of gas passing through a porous fabric. The most obvious of these is a ‘sieving’ mechanism in which particles too large to pass through the mesh of the fabric are caught and retained on the surface of the filter. The caught particles gradually build up a cake on the fabric surface so that the labyrinthine nature of the gas flow path continually increases while the effective mesh size decreases. The collecting efficiency of the filter will therefore tend to be improved by use, but the pressure drop across the filter will increase, of course, and so regular cleaning is essential to maintain the pressure drop at an operational level.

The less obvious, but for very fine particles, more important, mechanism of filtration is that in which the particles are caught by impingement on the fibres within the filter fabric. This is often referred to as ‘depth filtration’ to distinguish it from ‘sieving’. It is for this reason that filters usually consist of a fibrous mat, called needlefelt, rather than a single woven fabric screen. The actual flow paths followed by the gas passing through a depth filter are thus extremely tortuous, and a particle unable to follow these paths is given a trajectory which sooner or later brings it into contact with a fibre where it adheres, largely as a result of Van der Waal’s forces.

Collecting efficiency

The collecting efficiency of a fabric filter is mainly influenced by the gas velocity through the fabric, and the size of particle to be collected. Where the particles are relatively large, which means greater than about 5 J..m, they are likely, because of their greater inertia, to come frequently into contact with the filter fibres. The tendency to ‘bounce’ off the fibres and escape from the filter, however, is also greater, especially where the gas velocity is high. Where the solids loading is low, the performance of the filter may be improved by wetting the fabric to enhance the adhesive properties of the fibres. The method of cleaning the filter bags and their length also have an influence on collecting efficiency, as will be considered later.

Filter media

A wide range of materials is available for the manufacture of filter fabrics. Wool or cotton, the latter particularly having the advantage of low cost, may be used. For better resistance to abrasive wear or chemical attack, and a higher maximum operating temperature, however, either glass fibre or one of a number of alternative man-made fibres should be selected, such as Polyethylene, Polypropylene, Nylon (polyamide), Orlon (acrylic), Dacron (polyester), Teflon (PTFE), etc.

Apart from the properties of the fibres themselves, specifications for filter fabrics should include the ‘weight per unit area’, which gives an indication of the thickness, and therefore the strength and durability of the fabric, and an indication of its permeability.

The permeability of the material depends upon the construction of the fabric, which is a function of whether it is woven or felted, its thickness, tightness of weave, and so on. This information allows an estimate of the pressure drop across a filter to be made. Various surface treatments may also be carried out on filter fabrics by the manufacturer, the principal aim being to reduce the adhesion of caked solids to the fabrics, and thus render the cleaning process easier and more effective. Filter surfaces may also be treated to increase their resistance to combustion.

Selection criteria

The selection of a fabric filter for a given application should be made after consideration of a number of criteria. The first of these should be the particle size range, the nature of the solid material to be collected and the temperature of the conveying gas, which will dictate the types of fabric that would be acceptable. The size of unit required will depend principally upon the maximum gas flow rate to be handled, and the maximum allowable pressure drop.

The size will also be influenced by the proportion of solid material carried by the gas, the method of cleaning to be used, and the planned frequency of replacement of the filter fabric. Several of these criteria are clearly affected by cost factors, and so a careful balance must be struck between the capital cost of the equipment, normal running costs and the cost of routine maintenance.

Bag filters

In pneumatic conveying systems handling fine or dusty material, the method of filtration that has become almost universally adopted is a bag type fabric filter, either used on its own or as a ‘back-up’ to one of more cyclone separators. They may have application as bin vents in situations where all the solid material to be collected is blown into a hopper, and the clean air is vented off at the top through the filter unit, while the collected material is discharged from the base of the hopper through a suitable airlock.

The actual configuration of the filter bags within the unit, and the method of cleaning vary from one manufacturer to another. The bags are usually of uniform cross section along their length and the most common shapes are circular to or rectangular. Rectangular bags probably provide a filter unit with the largest fabric surface area to filter volume.

The cleaning process is of particular importance since it has a considerable influence on the size of filter required for a given application. Figure 7.6 illustrates diagrammatic- ally a typical form of bag filter unit. Although the filter bags shown in Figure 7.6 are suit- able for continuously operating systems, the method of cleaning is only suitable for batch conveying operations, for filter surfaces cannot be cleaned effectively by shaking unless the flow of air ceases.

The gas–solid stream enters the device from beneath the fabric bags so that larger particles are separated by gravity settling, often aided by a cyclone action, although this is not necessary, provided that direct impingement of particles on the bags from the conveying line is prevented. Fine particles are then caught on the insides of the fabric bags as the gas flows upwards through the unit.

These filters are available in a very wide range of sizes, lengths, shapes and configurations. The shaking mechanism represented in Figure 7.6 is one of several methods of bag cleaning that may be employed.

Filter size

The basic measure of filter size is the effective surface area of fabric through which the gas has to pass. It is usual, in the case of pneumatic conveying systems, to specify the size of filter required on the basis of an assumed value of the so-called ‘air to fabric ratio’, which is defined as the ratio of the volumetric air flow rate divided by the effective area of the filter fabric. It should be noted that this parameter is not, in fact, a ratio but has the dimensions of velocity. It is perhaps best regarded as a superficial velocity of the air through the filter fabric.

The actual value of the air to fabric ratio to be used depends upon several factors, as indicated previously and, although there have been attempts to develop theoretical expressions for the prediction of this parameter in various situations, none is really satisfactory, and reliance must be placed on experience. The manufacturers of filter units should normally be able to advise on suitable air to fabric ratios for the bulk particulate material being handled.

Typical values for felted fabrics are in the region of about 0.025 m/s for fine particulate materials and up to about 0.050 m/s when handling coarser or granular materials.

For woven fabrics, however, these figures should be halved, since the free area actually available for gas flow is much less.

Filter cleaning

The design of present-day fabric filter units, with their multiple bags or envelopes and their complex cleaning mechanisms, has gradually evolved with increasing awareness of the need to conserve energy and to avoid atmospheric pollution. The use of multiple bags was simply a means of getting a larger area of fabric into a small space, but a more important aspect of filter design, concerned the method of minimizing the pro- portion of fabric area out of action at any one time for cleaning.

This consideration led to the introduction of filter units having two or more separate compartments, each containing a number of bags. By this means one compartment could be shut off for cleaning while the others remained in service, handling the full gas–solid flow. Modern filter units using pulsed air jets for fabric cleaning do not require the unit to be compartmentalized, but are still designed to ensure that only a small number of bags are out of service at the same time.

There are two basic types of cleaning action that can be employed. These are mechanical shaking and air pulsing. The former system, illustrated in Figure 7.6, tends to be cheaper, but its application is restricted to batch operations. The cleaning will not function properly when on load, and so the filter can only be shaken effectively at the end of a conveying cycle in the absence of air and material flow. It is also restricted to installations handling materials which readily form a caked layer on the surface of the filter fabric. Shaking the framework on which the bags are mounted causes a flexing or rippling movement of the fabric which results in the material being dislodged and falling into the collecting hopper.

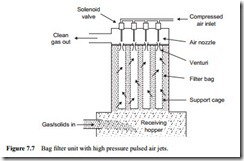

Reverse air jet cleaning

An alternative method of causing the filter fabric to flex and so dislodge caked material is to arrange for a periodic reversal of the direction of gas flow through the fabric. This may be achieved either by diverting the total flow of cleaned gas back through one section of the filter, or by a system of high pressure jets, operating in sequence, which inject cleaned air downwards through the bag walls in the reverse direction to the nor- mal air flow. Such a device is shown in Figure 7.7 and this is very much the industry standard at the present time.

The pulsed reverse air jets last for only a very short period of time, typically less than a second, and so continuous operation of the filter is possible, and maximum utilization of the fabric area can be achieved. The air is generally pulsed through a venturi positioned at the inlet to the bag, and the bags are usually supported by a wire cage. The high pressure air pulsed through the venturi creates a shock wave and it is this, in combination with the reverse flow of air, that results in the cleaning of the filter bag.

There is clearly a limit to the length of filter bag that can be effectively cleaned by this means, and a reduction in cleaning efficiency must be expected if very long bags are used. Neither the pulse of air in the reverse direction, nor the shock wave will be

effective at the base of long bags. This is more so with filters in the form of closely packed envelopes than it is with cylindrical bags.

Maintenance

From a maintenance point of view it is desirable to size a filter to have as low a value of face velocity as is economically possible. The particles are then not forced into the fabric, eventually to be permanently trapped in the fabric pores, but to stay near the outer surface for easy removal by the cleaning action. The permanent trapping of particles builds up the residual pressure drop of the fabric and once the pressure drop continually increases, despite more intensive cleaning, the fabric is said to be blinded.

Other particles are not necessarily trapped by the fabric but are driven by the high velocity right through the matrix of fibres to emerge on the clean side, having penetrated the fabric. Increased penetration and hence emission is one of the penalties for the excess velocity that results. It is at this stage that the filter bags should be replaced.