BREATHING AIR FILTRATION

The purity requirements for compressed air used for respiration and hygienically critical applications such as hospital patient recovery and life support in hazardous environments such as mines, underwater tanks, etc,must be free of toxic or irritating ingredients, odours dust and solid particles.

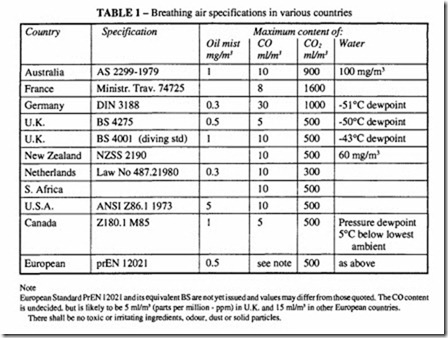

Numerous organisations and agencies around the world have established specifications pertaining to the purity of compressed air for human respiration. Although variations in requirements exist, mainly due to the method and type of application, it can be seen from Table 1 that there is substantial agreement between the various standards.

is undecided. but is likely to be 5 mllm’ (parts per million- ppm) in U.K. and 15 mllm’ in other European countries.

There shall be no toxic or irritating ingredients, odour. dust or solid particles.

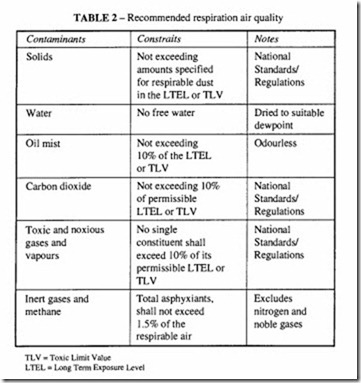

For the U.K., 10% of the values included in EH40/94 Occupational Exposure Limits, published by the Health and Safety Executive (HSE Books) would be appropriate as a guide to recommended maximum contaminants; this is likely to be embodied in the British version of the proposed new European Standard BS EN12021. See also Table 2.

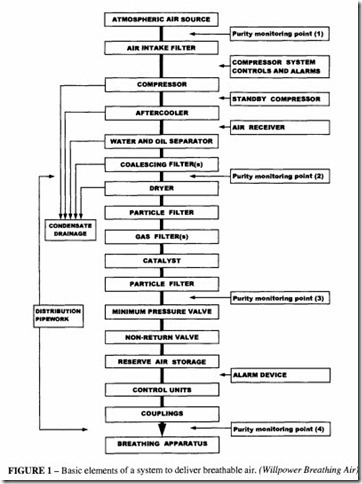

The most common method of producing compressed air for human respiration is by the compression of normal atmospheric air. Compressors may be any of those discussed in early chapters, although it is preferable to use one which is oil free, if that is the only purpose for which air is generated. The choice will also depend on the pressure at which the air has to be used and the volume rate of delivery.

In low pressure industrial systems below 6 bar, the breathing air supply can be tapped directly off the working main. This puts a higher premium on the quality of the working main, even though the breathing air will be separately filtered. Figure I shows the basic elements of a system capable of delivering breathable air. A lower level of air preparation will be unlikely to meet the forthcoming requirements of the revised version of BS 4275 and the proposed EN 12021. With all compressors intended to be used to supply breathing air, the main requirement is that it shall induct only uncontaminated air. The flow required

must be based on the recommendations of the manufacturer of the air line respiratory protective equipment.

Contaminants

Table 3 shows the major contaminants that can be present in air lines.