Energy considerations

In Chapter 6 on Air movers, the use of pre-cooling systems for compressors was introduced and it was mentioned that significant energy savings could be made. In order to be able to assess the energy requirements for this type of system the energy model is presented here. From the above consideration of moisture and condensation it will be seen that the analysis will have to include elements for air, water and steam.

Steady Flow Energy Equation

The Steady Flow Energy Equation in its full form is as follows:

where Q is the heat transfer (kW); W, the work transfer (kW); m, the mass flow rate (kg/s);

h, the specific enthalpy (kJ/kg); C, the velocity (m/s); g, the gravitational acceleration (m/s2); z, the elevation (m) and subscripts 1 and 2 relate to inlet and outlet conditions.

Some of these energy quantities may be zero, such as heat and work transfers, and many will be negligibly small, such as changes in kinetic and potential energy. The mass flow rate, . terms will apply to each constituent; air, water and steam.

Note that:

where hv is the enthalpy of superheated vapour (kJ/kg); hg, the enthalpy of saturated vapour (kJ/kg); t, the actual temperature °C; and tg, the saturation temperature °C.

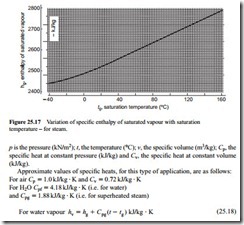

Values of hg are given in Figure 25.17. Although values of specific humidity may be low, it will be seen from Figure 25.17 that specific enthalpy values of the vapour are extremely high, and so the energy quantities associated with the vapour can be very significant.

The datum for the specific enthalpy values in Figure 25.17 is taken as 273.16 K, which is the ‘triple point’ of water, which is 0.01°C, and so 0°C is taken as the datum for all thermal energy quantities in the Steady Flow Energy Equation. This means that Celsius temperatures can be used directly, as shown in Equations (25.16)–(25.18), instead of absolute values, which are essential for the Ideal Gas Law.

Evaporative cooling

In dealing with the staging of positive displacement blowers, in Chapter 6 on Air movers, it was mentioned that water sprays could be used to reduce the temperature of the outlet air, instead of a conventional heat exchanger. A water consumption figure was given as 2 per cent of the air flow rate. This case will be used as an example of applying the Steady Flow Energy Equation.

It will be assumed that 0.5 kg/s of air (24.5 m3/min at free air conditions), having a relative humidity of 70 per cent, is drawn into the compressor at a pressure of 101.3 kN/m2 absolute (standard atmospheric pressure) and at a temperature of 20°C. The air is delivered at a pressure of 201.3 kN/m2 absolute (1 bar gauge) and at a tem- perature of 100°C; 0.01 kg/s of water (2 per cent of 0.5) at a temperature of 20°C is sprayed into the air stream at exit from the compressor.

For the evaporative cooler it can be assumed that there will be no work done, and heat exchange with the surroundings can be neglected. It can also be assumed that all kinetic and potential energies can be disregarded. Thus the only energy into the sys- tem is that of the enthalpies of the air, water and vapour, as evaluated above at 64.2 kW. At outlet it will be assumed that all the water is evaporated and so only the enthalpies of the air and vapour need be taken into account.

At outlet from the evaporative cooler at ②:

From which the relative humidity is 75 per cent, and so all the water will have evaporated, residence time permitting. From this it will be seen that the cooling effect of water, because of the very high enthalpy of evaporation, hfg, can be very effective, and that the enthalpy term for vapour should always be included in any energy analysis of a system.

Flash drying

A flash dryer is essentially a pneumatic conveying system. It consists mainly of a vertically upward section of duct. Wet material is fed in at the bottom and is conveyed up by hot air or gas. The dried material is removed either by cyclone separator or bag fil- ter. The vertically upward flow allows intimate mixing, and a reasonable residence time for the necessary mass transfer process to take place. The evaporation of the moisture from the wet material rapidly cools the hot air, and so the method of drying is generally suitable for most powdered and granular materials, including many heat sensitive products.

The Steady Flow Energy Equation can be used to model this type of system also, knowing the moisture content and flow rate of the feed material. As with the evaporative cooling case considered above, there will be no work transfer, heat transfer to the surroundings can be neglected, and changes in kinetic and potential energy can generally be neglected. In addition to allowing for flows of water, air and vapour, however, account also has to be taken of the conveyed material. Specific heat values of a number of materials were given in Table 9.4.

Vacuum drying

In the heating of a material the driving force is temperature difference, and the greater the temperature difference the faster the material will be heated, or cooled. For the flow of a fluid the driving force is pressure difference. In the case of the drying of wet bulk particulate materials the driving force is the difference in vapour pressure, and this can reasonably be related to relative humidity difference. When the material is wet, or frozen, the air in intimate contact with the material, in the boundary layer, will be saturated and have a relative humidity of 100 per cent. The lower the relative humidity of the body of drying air in contact with the material, the greater the drying effect will be.

In the flash dryer, considered above, the drying air is given an extremely low value of relative humidity by means of heating to a high temperature. Saturated air at 20°C, when heated to 100°C, for example, will have a relative humidity of about 2 per cent. Relative humidity, however, can be lowered in a similar manner by reducing pressure, and this effect was shown earlier in Figure 25.5. Saturated air, at 20°C and atmospheric pressure, will have a relative humidity of about 20 per cent when the pressure is reduced to -0.8 bar of vacuum (21.3 kN/m2 absolute). A difference in temperature, therefore, is not a necessary requirement for drying. Dehumidified air, dried with a desiccant type dryer, can also be used to dry wet materials at atmospheric temperature. Combinations of any of these three methods of reducing the relative humidity of the drying air can be used to speed the process.

Vacuum drying of materials at very low pressures is usually a batch operation, and as extremely low values of relative humidity can be achieved, the drying process is reasonably quick. With no requirement for heat it is ideal for heat sensitive materials. With the potential for achieving very low values of relative humidity, particularly when the atmospheric air is fairly dry, consideration must be given to the drying of materials when pneumatically conveyed in vacuum conveying systems.