Flow charts

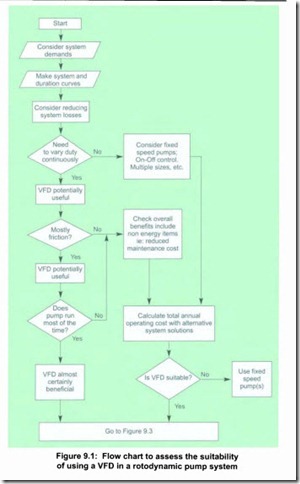

Flow charts to assess the suitability of a VSD for a pump system are shown in Figures 9.1 for rotodynamic pumps and 9.2 for positive displacement

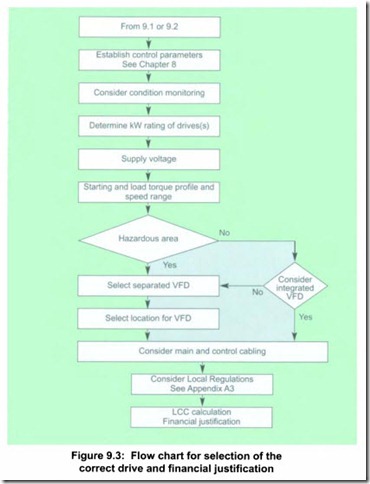

pumps. These are based on using a variable frequency drive, which will be more efficient than any speed control device, which uses slip to vary the speed. Having established that using a VFD is appropriate, Figure 9.3 is a flow chart for selecting the correct drive and making the life cycle cost calculation. Chapter 12 will help in making the financial justification.

Appendix A2.4 contains information on the factors to be considered in sizing a drive.

Related posts:

Case studies:Benefits given by the use of environmental temperature control using reciprocating PD p...

Concepts for estimating pumping energy costs:Flow regulated by throttling

PNEUMATIC SEALS

Air only relationships:Venturi analysis and High pressure applications.

Air flow rate evaluation:Supply pressure and Volumetric flow rate.

Basic principles:nomenclature and units

Low pressure and vacuum:Screw feeders and The simple screw feeder.

Hydraulic fluids:Neutralization number

Seals: Rotary actuators and Constructional details.

Control valves.

Hydraulic Pumps and Pressure Regulation

PROPERTIES OF PURE SUBSTANCES:INTERNAL ENERGY, ENTHALPY, AND SPECIFIC HEATS OF IDEAL GASES

THE SECOND LA W OF THERMODYNAMICS:THE CARNOT CYCLE

ENTROPY:ENTROPY BALANCE

SUMMARY OF ENTROPY