LINES, FITTINGS, AND SEALS

The control and application of fluid power would be impossible without suitable means of transferring the hydraulic fluid between the reservoir, the power source, and the points of application. Fluid lines are used to transfer the hydraulic fluid, fittings are used to connect lines to system components, and seals are used in all components to prevent leakage. This chapter is devoted to these critical system components.

TYPES OF LINES

Three types of lines are used in fluid power systems: pipe (rigid), tubing (semirigid), and hoses (flexible). A number of factors are considered when the type of line is selected for a particular application. These factors include the type of fluid, the required system pressure, and the location of the system. For example, heavy pipe might be used for a large, stationary system, but comparatively lightweight tubing must be used in mobile applications. Flexible hose is required in installations where units must be free to move relative to each other.

PIPE AND TUBING

There are three important dimensions of any tubular product: outside diameter (OD), inside diameter (ID), and wall thickness. Sizes of pipe are listed by the nominal, or approximate, ID and the wall thickness. The actual OD and the wall thickness list sizes of tubing.

Selection

The material, inside diameter (ID), and wall thickness are the three primary consider ations in the selection of lines for a particular fluid power system. The ID of the line is important because it determines how much fluid can pass through the line without loss of power due to excessive friction and heat. The velocity of a given flow is less through a large opening than through a small opening. If the ID of the line is too small for the amount of flow, excessive turbulence and friction will cause unnecessary power loss and overheat the hydraulic fluid.

Sizing

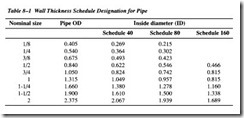

Pipes are available in three different weights: Standard (STD), or Schedule 40; Extra Strong (XS), or Schedule 80; and Double Extra Strong (XXS). The schedule numbers range from 10 to 160 and cover 10 distinct sets of wall thickness (Table 8-1). Schedule 160 wall thickness is slightly thinner than the double extra strong.

As mentioned earlier, the nominal inside diameter (ID) determines the size of pipes. For example, the ID for a 1/4-inch Schedule 40 pipe is 0.364 inch, and the ID for a 1/2-inch Schedule 40 pipe is 0.622 inch.

It is important to note that the IDs of all pipes of the same nominal size are not equal. This is because the OD remains constant and the wall thickness increases as the sched ule number increases. For example, a nominal l-inch Schedule 40 pipe has a 1.049-inch ID. The same size Schedule 80 pipe has a 0.957-inch ID, while Schedule 160 pipe has 0.815-inch ID. In each case the OD is 1.315 inch and the wall thickness varies. The actual wall thickness is the difference between the OD and ID divided by 2.

Tubing differs from pipe in its size classification. Its actual outside diameter (i.e., OD) designates tubing. Thus, 5/8-inch tubing has an OD of 5/8 inch. As indicated in Table 8-2, tubing is available in a variety of wall thicknesses. The diameter of tubing is often measured and indicated in l/16ths. Thus, No. 6 tubing is 6/16 or 3/8-inch OD, No.8 tubing is 8/16 or 1/2-inch, and so forth.

The wall thickness, material used, and ID determine the bursting pressure of a line or fitting. The greater the wall thickness in relation to the ID and the stronger the metal,

the higher the bursting pressure. However, the greater the ID for a given wall thick ness, the lower the bursting pressure. This is because force is the product of area and pressure.

Materials

The pipe and tubing used in fluid power systems are commonly made from steel, cop per, brass, aluminum, or stainless steel. Each of these metals has its distinct advan tages and disadvantages in certain applications.

Steel pipe and tubing are relatively inexpensive and are used in many hydraulic and pneumatic applications. Steel is used because of its strength, suitability for bending and flanging, and adaptability to high pressures and temperatures. Its chief disadvan tage is its comparatively low resistance to corrosion.

Copper pipe and tubing are sometimes used for fluid power lines. Copper has high resis tance to corrosion and is easily drawn or bent. However, it is unsatisfactory for high temperatures and has a tendency to harden and break because of stress and vibration.

Aluminum has many of the characteristics and qualities required for fluid power lines. It has high resistance to corrosion and is easily drawn or bent. In addition, it has the outstanding characteristic of light weight. Since weight elimination is a vital factor in the design of aircraft, aluminum alloy tubing is used in the majority of aircraft fluid power systems.

An improperly piped system can lead to serious power loss and possible harmful fluid contamination. Therefore, in maintenance and repair of fluid power system lines, the basic design requirements must be kept in mind. Two primary requirements are as follows:

1. The lines must have the correct ID to provide the required volume and velocity of flow with the least amount of turbulence during all demands on the system.

2. The lines must be made of the proper material and have the wall thickness to provide sufficient strength to both contain the fluid at the required pres sure and withstand the surges of pressure that may develop in the system.

Preparation

Fluid power systems are designed as compactly as possible, to keep the connecting lines short. Every section of line should be anchored securely in one or more places so that neither the weight of the line nor the effects of vibration are carried on the joints. The aim is to minimize stress throughout the system.

Lines should normally be kept as short and free of bends as possible. However, tubing should not be assembled in a straight line, because a bend tends to eliminate strain by absorbing vibration and also compensates for thermal expansion and contraction.

Bends are preferred to elbows, because bends cause less loss of power. A few of the correct and incorrect methods of installing tubing are illustrated in Figure 8-1.

Bends are described by their radius measurements. The ideal bend radius is 2-1/2 to 3 times the ID, as shown in Figure 8-2. For example, if the ID of a line is 2 inches, the radius of the bend should be between 5 and 6 inches.

Although friction increases markedly for sharper curves than this, it also tends to increase up to a certain point for gentler curves. The increases in friction in a bend with a radius of more than 3 pipe diameters result from increased turbulence near the outside edges of the flow. Particles of fluid must travel a longer distance in making the change in direction. When the radius of the bend is less than 2-1/2 pipe diameters, the increased pressure loss is due to the abrupt change in the direction of flow, especially for particles near the inside edge of the flow.