Recent developments

Although pneumatic conveying systems have numerous advantages over alternative mechanical conveying systems for the transport of materials, they do have drawbacks, particularly for materials that can only be conveyed in dilute phase. Particle degradation and erosive wear of pipeline bends are particular examples. Due to the high conveying air velocity required, energy requirements are also high.

In recent years there have been many developments of pneumatic conveying systems aimed at increasing their capability for conveying a wider range of materials in dense phase, and hence at low velocity. This has generally been achieved by condi- tioning the material at the feed point into the pipeline, or by providing a parallel line along the length of the pipeline to artificially create either permeability or air retention in the material.

System types

Pneumatic conveying system types can be divided into conventional and innovatory types. In conventional systems the material to be conveyed is simply fed into the pipe- line and it is blown or sucked to the discharge point. It must be realized that low vel- ocity, dense phase, conveying in conventional pneumatic conveying systems is strictly limited to materials that have the necessary bulk properties of good air retention or good permeability. The use of high pressure air is not synonymous with dense phase conveying. It is dictated entirely by the properties of the material to be conveyed in a conventional conveying system.

Probably the majority of materials that are conveyed have neither of these proper- ties. There has, therefore, been much research undertaken into pneumatic conveying with a view to developing systems that are capable of conveying a much wider range of materials in dense phase and hence at low velocity. Making these systems more suitable for abrasive and friable materials has provided a particular driving force.

Conveying capability

It has already been mentioned that pneumatic conveying systems are capable of conveying almost any material. Distance, however, does impose a practical limit. Although hydraulic conveying systems are capable of conveying material at a flow rate in excess of 100 tonne/h, over a distance of 100 km, or more in a single stage, the limit for pneumatic conveying is typically about 11⁄2 km for most applications.

With water having a density that is about 800 times greater than that of air, at free air conditions, the difference in density between the conveyed material and that of the conveying fluid is widely different. As a consequence conveying air velocities are a factor of about ten times greater than those required for water in order to convey material in suspension.

High pressure conveying

The biggest problem with high pressure for pneumatic conveying derives from Equation (1.2). Water can be modelled, as being essentially incompressible and so there is little change in velocity along the length of the pipeline. Water pressures up to about 150 bar are therefore used. With air being compressible very few systems, any- where in the world, operate at a pressure much above 5 bar gauge when delivering material to a reception point at atmospheric pressure.

In terms of pneumatic conveying, high pressure virtually means anything above 1 bar gauge. This is a typical operating limit with possibly the majority of pneumatic conveying systems in industry. This corresponds with a doubling in conveying air velocity, as mentioned above. With any higher air supply pressure it would always be recommended that the pipeline should be stepped to a larger bore part way along its length in order to prevent high values of velocity from occurring.

Apart from magnifying problems of erosive wear and particle degradation, velocity has an adverse effect on pressure drop. The appropriate relationship here is:

where p is the pressure drop, L, the length of straight pipeline, p, the air density, C, the conveying air velocity and d, the pipeline bore.

It will be seen from this that velocity is on the top line of the equation and its value has to be squared. This, therefore, is an extremely important term and anything that can be done to keep conveying air velocities to as low a value as possible is generally to be advised. In this respect the stepping of a pipeline is generally an advantage, not just in minimizing wear and degradation, but generally in terms of achieving an improvement in conveying performance.

A particular advantage of pneumatic conveying systems is that they can be operated at high pressure if required. There are many instances in industry where it is necessary to deliver bulk particulate materials into vessels that operate at high pressure. Again, by reference to Equation (1.2), it will be seen that this situation does not present a significant expansion problem. Thus coal, limestone and bed material, for example, can be delivered to high pressure fluidized bed combustors that operate continuously at pressures of about 20 bar gauge and above.

Long distance conveying

Thermal power stations often employ long distance pneumatic conveying in order to transfer the pulverized fuel ash to a point on the site boundary for subsequent disposal. At a power station in Ropar, India, the Punjab State Electricity Board operates a plant consisting of six 210 MW generating units. Dry ash is conveyed from the electrostatic precipitators to a group of five storage silos, a distance of about 2 km, where it is avail- able to cement manufacturers. The transfer is in two stages: The first conveys the ash from the electrostatic precipitators to two intermediate storage silos over a distance of 400 m. Denseveyor ash vessels are used, the lines are 200 mm bore and 30 tonne/h per line is achieved.

In the second stage the ash is conveyed over a distance of 1550 m at a rate of 40 tonne/h per line. Twin blow tanks are used (three to each intermediate silo) and the pipelines are stepped from 200 to 250–300 mm bore. Four compressors are available to each silo, with two working and two on standby, each delivering 72 m3/min at 4.2 bar gauge. This plant was commissioned in 1995. Several similar long distance pipelines have been built at power stations in India, some with much higher conveying capacities.

Vertical conveying

Most pneumatic conveying systems have an element of vertical conveying in the pipe- line run. In the majority of pipelines it is usually conveying vertically up, and at the end of the pipeline, in order to discharge the material into a hopper or silo. The routing of the pipeline may include vertically up and vertically down sections to cross roads or railways, or to avoid obstructions or accommodate existing pipe racking.

Flow vertically up and down presents no undue problems, and is potentially easier, since the minimum conveying air velocity for flow vertically up is generally lower than that for horizontal flow. It is not often that advantage can be taken of this since most pipelines incorporate combinations of both horizontal and vertical pipeline. Since horizontal pipeline usually predominates, conveying air velocities are generally specified in terms of those required for horizontal conveying. It is probably in mining applications that significant lengths of vertical pipeline are found.

Conveying vertically up

In many old collieries, mechanization of coal cutting meant that the existing shaft winding gear could not cope with the increased output. This was the situation in the UK in the early 1970s, and so an economical means of increasing capacity had to be found. Of all the possible hoisting systems examined, the positioning of pipelines in the corner of existing shafts appeared to offer the best solution. Although the operat- ing cost for pneumatic conveying systems was recognized as being high, the time and capital cost elements were very much in their favour.

Onley and Firstbrook [1] reported on tests undertaken at a coal mine having a 200 mm bore pipeline with a 420 m vertical lift; 18.6 tonne/h of -50 mm dolomite was conveyed with a pressure drop of 1.37 bar. With coal, 42 tonne/h was achieved with a conveying line pressure drop of 1.72 bar, although with wet -25 mm shale only 23 tonne/h could be achieved with the same air supply pressure.

At another UK colliery the pipeline bore was 300 mm and the vertical lift was 326 m [1]. In this case there were horizontal runs of 100 m from the feed point and 54 m to the reception point. 66 tonne/h of -25 mm coal was conveyed with an air supply pressure of 0.75 bar. The blower had a capacity of 1.0 bar, was provided with a 522 kW motor drive, and could deliver 3.7 m3/s of air. It was subsequently reported that 80 tonne/h was achieved at this installation [2].

Conveying vertically down

Pulverized fuel ash, or fly ash, is often available at coal mines, particularly if a power station is built close to the mine. Disposal of this ash underground for back-filling is generally considered to be environmentally better than many surface alternatives. Cement is another material that is commonly used in back-filling operations. Curten [3] reports that typical applications involve the transport vertically down 700–1000 m and then directed up to 2000 m into the underground roadways. He reports that the dis- tances are dependent upon the type of material conveyed and that considerably longer distances (up to 7000 m) can be achieved if pulverized material is transported compared with granular support material.

Associated with deep level mining is the problem of providing a tolerable working environment. For this purpose underground refrigeration plants, evaporative cooling and the pumping of chilled water from surface refrigeration plants to underground heat exchangers are some of the methods employed. Sheer et al. [4] reported on the use of ice in South African gold mines for this purpose. By virtue of latent heat considerations, four times less water needs to be pumped when using ice in preference to chilled water. Ice making plant is located at the surface level and the ice produced is pneumatically con- veyed over distances up to about 5 km, with vertically down distances up to about 2400 m.

Flow rate capability

The capability of a pneumatic conveying system, in terms of achieving a given mater- ial flow rate, depends essentially on the conveying line pressure drop available and the diameter of the pipeline. As mentioned above, the use of pressure is generally limited in the majority of applications to about 5 bar and so pipeline bore is increased to achieve an increase in material flow rate if this is required.

In many cases pressure capability is set by the desire to use a particular type of compressor or blower. In most cases the duty of conveying a given flow rate of material can be met by a wide range of combinations of pressure drop and pipeline bore. There is rarely a single solution to the design of any pneumatic conveying system. Where there is a choice it is well worthwhile comparing the systems in terms of operating cost as well as capital cost. Only if a very high material flow rate is required will the options be limited.

Lithgart [5] reports on a pneumatic system for off-loading cement from bulk car- riers at 800 tonne/h, and its onward conveying to silos 500 m distant through twin pipelines. Castle Cement had a need to import up to one million tonne/year of cement at a terminal 20 km east of London on the River Thames. As the river is tidal (7 m) it was necessary to build a jetty in the river against which the ships could berth, and hence the long conveying distance.

A single vacuum nozzle was employed to off-load at 800 tonne/h, but it was decided to use two pipelines at 400 tonne/h each for the transfer to the silos, as it was con- sidered that a single bore pipeline would be more expensive to build. It was estimated that the power required for conveying the cement at 800 tonne/h to the silos was 2400 kW.

Pressure gradient influence

Conveying distance has a very significant influence on pneumatic conveying system performance. Assume, for example, that a system is capable of conveying 100 tonne/h over a distance of 100 m, with a pressure drop of 2 bar. If the distance is doubled, and there is no change in pressure, the material flow rate will be reduced by at least half, to a maximum of 50 tonne/h, if there is no change in pipeline bore, and hence air flow rate, and also power. With a halving of material flow rate and no change in air flow rate, the solids loading ratio will also be halved.

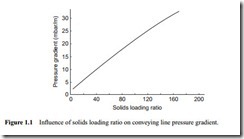

A high value of solids loading ratio must be maintained in order to convey a material in dense phase. With increase in conveying distance, this capability will be reduced because there is a limit with regard to air supply pressure to help in this respect. To illustrate this effect a graph of conveying line pressure gradient is plotted against solids loading ratio in Figure 1.1. This is a very approximate relationship and only for illustration purposes, since there is no reference to either material type or conveying air velocity.

Pressure gradient is given in units of mbar/m. The distance in metres in this case is the equivalent length of the pipeline. In addition to the length of horizontal pipeline, therefore, an allowance is also included for the length of pipeline routed vertically up

and the number of bends in the pipeline. It will be seen that to convey at a solids load- ing ratio of about 100 requires a pressure gradient of about 20 mbar/m.

If only 2 bar is available for conveying, the maximum value of equivalent length possible will only be 100 m. If the equivalent length of a pipeline is 1000 m and 2 bar is available for conveying, the pressure gradient will only be about 2 mbar/m and so the maximum value of solids loading ratio at which the material can be conveyed will be about 10, which only relates to dilute phase conveying. A much higher pressure would be needed to maintain a dense phase conveying capability over this distance.

Material influences

It has already been mentioned that different materials have different conveying cap- abilities in terms of the minimum value of conveying air velocity required, and hence air flow rate. Different materials can also achieve very different mass flow rates when conveyed through the same pipeline under identical conveying conditions. And it is not just different materials! Different grades of exactly the same material can exhibit totally different performances. Thus a conveying system designed for one material may be totally unsuitable for another.