Pressure and temperature switches

Pressure switches

A pressure switch is an instrument that automatically senses a change in pressure and opens or closes an electrical switching element, when a predetermined pressure point is reached. A pressure-sensing element is that part of a pressure switch that moves due to the change in pressure. There are oasically three types of sensing elements commonly used in pressure switches:

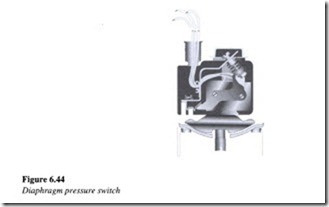

1. Diaphragm: This model (Figure 6.44) can operate from vacuum pressure up to a pressure of 10.5 kg/cm2 (150 psi). It consists of a weld-sealed metal diaphragm acting directly on a snap action switch.

2. Bourdon tube-type sensing element: This model (Figure 6.45) can operate with pressures ranging from 3.5 kg/cm2 (50 psi) to 1265 kg/cm2 (18 000 psi). It has a weld sealed bourdon tube acting on a snap action switch.

Figure 6.45

Bourdon tube pressure switch

3. Sealed piston-type sensing element: This type of sensing element can operate with pressures ranging from 1 kg/cm2 (15 psi) to 844 kg/cm2 (12 000 psi). It consists of an 0-ring-type-sealed piston direct acting on a snap action switch (Figure 6.46).

Figure 6.46

Sealed piston pressure switch

The electrical switching element in a pressure switch, opens and closes an electrical circuit in response to the actuating force received from the pressure-sensing element.

There are two types of switching elements:

1. Normally open

2. Normally closed.

A normally open switching element is one in which the current can flow through the switching element only when it is actuated. The plunger pin is held down by a snap action leaf spring and force must be applied to the plunger pin to close the circuit. This is done by an electrical coil which generates an electromagnetic field, when current flows through it. In a normally closed switch, current flows through the switching element until the element is actuated, at which point it opens and breaks the current flow.

Temperature switch

A temperature switch is an instrument that automatically senses a change in temperature and opens or closes an electrical switching element when a predetermined temperature

level is reached. Figure 6.47 is an illustration of a common type of temperature switch which has an accuracy of ±1 °F maximum.

Figure 6.47

Temperature switch

This temperature switch is provided with an adjustment screw at the top end in order to change the actuation point. In order to facilitate its mounting on the hydraulic system whose temperature is to be measured, the bottom end of the switch is provided with threads. As in the case of pressure switches, temperature switches can also be wired either normally open or normally closed.