Breathing apparatus standards

BS 4275, which has already been referred to, includes recommendations for the selection and maintenance of respiratory protective apparatus. It is currently being revised to bring it into line with current legislation.

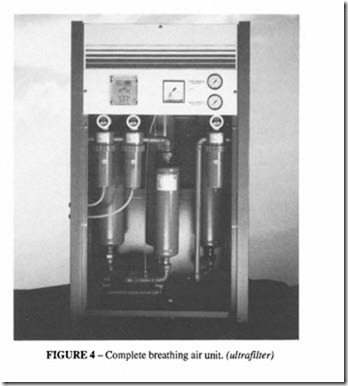

BS 4667 can be studied, particularly Part 3 which deals with compressed air line breathing apparatus, which is used in industry for paint spraying and for work in hazardous atmospheres. It is however being superseded by a range of European Standards, in particular: BSEN 139, BSEN 270, BSEN 271, prEN 1835, prEN 12419 Compressed air apparatus is supplied with clean air through a small diameter hose which is connected to a pressure reducer attached to the wearer. A larger hose takes air from the reducer to the face piece. The air supply may be continuous and controlled at a higher rate than the maximum needed during inhalation or it may be controlled by a demand valve. Of these there are two types, one which opens only when there is a negative pressure in the face piece, and one which maintains a slight positive pressure. The exhaust valve has in both cases to be set to open at a positive pressure at which the inlet or demand valve closes. Flexible hoses should not be longer than 90 metres and this type of respirator should not be used in situations where there would be a danger to life if the supply failed,

unless the apparatus includes an emergency breathing facility. The appropriate filters and drains should be provided in the supply line. Compressed air line breathing apparatus offers little resistance to breathing, so it can be used for long periods without fatigue. Its main disadvantage is the restrictions it places on the mobility of the wearer, so it cannot be used for fire fighting or rescue.