Flovvrneters

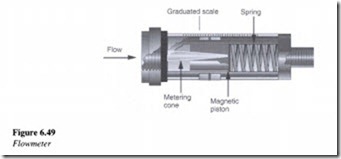

Flowmeters are used to measure flow in a hydraulic circuit. As shown in Figure 6.49, flowmeters mainly comprise of a metering cone and a magnetic piston along with a spring, for holding the magnetic piston in the no-flow position.

Flow meters are normally not bi-directional in nature. They in fact act as check valves and block flow in the reverse direction. Initially the fluid entering the device flows around the metering cone, exerting pressure on the magnetic piston and spring. With increase in flow in the system, the magnetic piston begins compressing the spring and thereby indicates the flow rate on a graduated scale.

Related posts:

Applications on pneumatic:Air gauging

Steam sterilization and Validation

FORCES IN LIQUIDS:LIQUIDS AT REST (HYDROSTATICS)

Pressure and flow:Flow

Hydraulic pumps and pressure regulation:Pressure regulation.

Air Compressors, Air Treatment and Pressure Regulation:air receivers and compressor control

Actuators:linear actuators

Process Control Pneumatics:signals and standards

Sequencing Applications:logic elements

SUMMARY OF ENERGY TRANSFER BY HEAT,WORK,AND MASS

THE SECOND LA W OF THERMODYNAMICS:HEAT ENGINES

ENTROPY:PROPERTY DIAGRAMS INVOLVING ENTROPY

POWER AND REFRIGER A TION CYCLES:AIR-STANDARD ASSUMPTIONS

RADIATION HEAT TRANSFER: DIFFUSE, GRAY SURFACES

RADIATION HEAT TRANSFER:RADIATION SHIELDS AND THE RADIATION EFFECTS