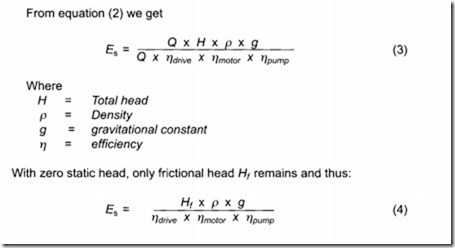

Systems without static head or closed loop systems

The specific energy here is dependent on the frictional head loss which, in turn, is determined by the losses in the pipe system (including throttling valves), and by the combined drive-motor-pump efficiency.

The combined drive-motor-pump efficiency has to be evaluated for each duty point. It is to be noted that the pump efficiency remains approxi mately the same in a system of this type when the speed is changed, whereas the drive-motor efficiency can drop drastically as the load is reduced. If on the other hand, the system curve is changed by changing the setting of a valve, this will change the duty point of the pump and, hence, its efficiency.

Related posts:

Air only relationships:Air flow rate control

THE COMPRESSOR:AIR RECEIVERS

Basic principles:nomenclature and units

Conveying characteristics:The determination of conveying characteristics

MAINTENANCE OF HYDRAULIC SYSTEMS:ROOT CAUSE FAILURE ANALYSIS

ROUBLESHOOTING HYDRAULIC SYSTEMS:ISOLATING PROBLEMS IN A HYDRAULIC CIRCUIT

HYDRAULIC FLUIDS:Density and Specific Gravity

BASIC HYDRAULICS:STATES OF MATTER.

LINES, FITTINGS, AND SEALS:TYPES OF FITTINGS AND CONNECTORS

Fault-finding instruments.

Air Compressors, Air Treatment and Pressure Regulation

THE FIRST LAW OF THERMODYNAMICS:ENERGY BALANCE FOR CLOSED SYSTEMS

SUMMARY OF THE FIRST LAW OF THERMODYNAMICS

FORCED CONVECTION: PHYSICAL MECHANISM OF CONVECTION

SUMMARY OF FORCED CONVECTION