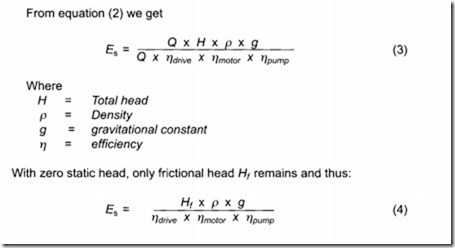

Systems without static head or closed loop systems

The specific energy here is dependent on the frictional head loss which, in turn, is determined by the losses in the pipe system (including throttling valves), and by the combined drive-motor-pump efficiency.

The combined drive-motor-pump efficiency has to be evaluated for each duty point. It is to be noted that the pump efficiency remains approxi mately the same in a system of this type when the speed is changed, whereas the drive-motor efficiency can drop drastically as the load is reduced. If on the other hand, the system curve is changed by changing the setting of a valve, this will change the duty point of the pump and, hence, its efficiency.

Related posts:

Case studies:Benefits given by the use of environmental temperature control using reciprocating PD p...

Pumps:Pump suction performance (NPSH)

Air flow rate evaluation:The influence of temperature and Conveyed material influences.

First approximation design methods:Empirical relationships

Low pressure and vacuum:Venturi feeders and Commercial venturi feeder

HYDRAULIC PUMPS:Centered Internal Gear

Hydraulic fluids:General types of fluids.

Hydraulic motors:Hydraulic motor performance

Types of control valve:Poppet valves,Spool valves and Rotary valves.

Pilot-operated valves.

Process Control Pneumatics:volume boosters

BASICCONCEPTS OF THE RMODYNAMICS:TEMPERATURE AND THE ZEROTH LAW OF THERMODYNAMICS

PROPERTIES OF PURE SUBSTANCES:THE IDEAL-GAS EQUATION OF STATE

FORCED CONVECTION:THERMAL BOUNDARY LAYER

NATURAL CONVECTION:NATURAL CONVECTION FROM FINNED SURFACES AND PCBs