COMPRESSED AIR FILTRATION

The properties of compressed air make it a versatile, secure and economic medium that is economic to produce and handle. Compressed air is used either as a carrier medium for the transport of energy to the point of use where its potential and kinetic energies can be converted into a driving force for pneumatic equipment, or as a process medium itself (eg breathing air) or for processing purposes (agitating, mixing, packaging, conveying and pressurising). These applications can be found discussed in other chapters in the book. For most applications of compressed air, a requirement of air quality exists, expressible as a permissible level of contaminants.

The purity demands of high precision complex and fully automated pneumatic systems and of chemical, biochemical, biomedical, electronic, pharmaceutical and food process ing applications increase year by year, requiring a continuously improving level of air treatment. The degree of treatment of air for tool use is clearly not so critical, so the air treatment equipment must be regulated to the end use.

Research indicates that contamination to the extent of 190 million dirt particles per cubic metre (even more in heavily industrialised areas) is commonplace. As much as 80% of these particles are smaller than 2 microns and pass straight through a compressor intake filter. This contamination is supplemented by water vapour and unburnt hydrocarbons from aviation, industrial and domestic heating and vehicle fuels. When this poor quality of air is compressed, the particle content increases to an excess of 1 billion particles per cubic metre.

The contaminants likely to be found in compressed air fall into the following categories:

• atmospheric dust, smoke and fumes inducted by the compressor

• atmospheric bacteria and viruses

• water vapour inducted and passed through the compressor

• gas generated in the compressor

• oil carried over from the compressor

• solid contaminants generated within the system

Compressed air quality classes for solids, water and oils are given in Table 1, in accordance with ISO 8573

To specify the quality class for a particular application, quote the three classes in turn, eg Quality class 2.2.2 is dirt lJ.lm, water -40°C, oil 0.1 mg/m 3 Refer to Table 2 for quality recommendations for typical applications.

Particles smaller than one-third of the smallest clearance they will have to pass through can generally, from purely mechanical considerations, be accepted. For average use in air lines supplying mechanical equipment, a filtration rating of 40 micron is usually adequate. The degree of treatment required for removing contaminants from a compressed air system depends on the application. For general industrial applications, eg compressed air mains for general factory use, partial water removal by aftercooling followed by filtering

to remove solid contaminants may be adequate. At the other extreme, two or more stages of filtration may be required, including oil removal, after which the air may be further conditioned by drying to provide humidity control.

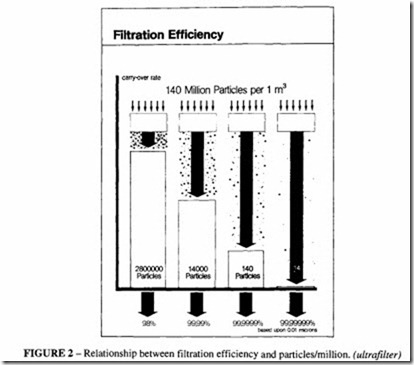

The relationship between filtration efficiency and number of particles in a cubic metre of air is illustrated in Figure 2.