Air compression effects

When compressed air is delivered into a pipeline for use, the air will almost certainly be very hot, and it may contain quantities of water and oil. Air delivery temperature and the problem of oil are considered in some detail at this point, but the specific subjects of moisture and condensation, and air drying, although introduced here, are considered generally and in more detail in Chapter 25. The power required to provide the com- pressed air, and hence the operating cost, can be very high, and this topic is also considered in some detail at this point.

Delivery temperature

Much of the work energy that goes into compressing air manifests itself in increasing the temperature of the air. For air compression to pressures greater than about 2 bar gauge air cooling is generally employed. The most efficient form of compression is to carry out the process isothermally, and so cylinders of reciprocating machines are often water cooled, and if staging is employed for achieving high pressures, inter-cooling is generally incorporated as well. For most high pressure machines that have some form of air cooling, therefore, the influence of air temperature can be neglected.

In the majority of dilute phase conveying systems, where a large volume of air is required at a relatively low pressure, positive displacement blowers are generally used. For this type of application they are not usually cooled and so the air, after compres- sion, can be at a fairly high temperature. Thermodynamic equations are available that will allow this temperature to be evaluated. Compression can be based on an isen- tropic model for which the relationship between the absolute pressure and the absolute temperature is given by:

where ‘Y is the ratio of specific heats, Cp/Cv = 1.4 for air and subscripts 1 and 2 refer to inlet and outlet conditions.

This is the ideal case. In practice the air will be delivered at a higher temperature than this due to thermodynamic irreversibilities. The compression process is adiabatic, partly because of the speed of the process, but it is far from being a reversible process. As a result, the temperature of the air leaving a compressor can be very high.

If, for example, air at a temperature of 20°C is compressed to 1 bar gauge in a positive displacement blower, the minimum temperature after compression, for a reversible process, would be about 84°C, and with an isentropic efficiency of 80 per cent it would be 100°C. Irreversibility is taken into account by means of an isentropic efficiency,

A graph showing the influence of delivery pressure and isentropic efficiency on delivery temperature is given in Figure 6.9. This covers the range of pressures appropriate to positive displacement blowers.

If air at 20°C is compressed to 3 bar gauge in a screw compressor it will be delivered at a temperature of about 200°C, which is why for air compression to pressures greater than about 2 bar gauge, air cooling is generally employed. Whether the air can be used to convey a material without being cooled will depend to a large extent on the proper- ties of the material to be conveyed.

Oil free air

Oil free air is generally recommended for most pneumatic conveying systems, and not just those where the material must not be contaminated, such as food products, pharmaceuticals and chemicals. Lubricating oil, if used in an air compressor, can be carried over with the air and can be trapped at bends in the pipeline or obstructions. Most lubricating oils eventually break down into more carbonaceous matter which is prone to spontaneous combustion, particularly in an oxygen rich environment, and where frictional heating may be generated by moving particulate matter.

Although conventional coalescing after-filters can be fitted, which are highly efficient at removing aerosol oil drops, oil in the super-heated phase will pass straight through them. Super-heated oil vapour will turn back to liquid further down the pipeline if the air cools. Ultimately precipitation may occur, followed by oil breakdown, and

eventually a compressed air fire. The only safe solution, where oil injected compressors are used, is to employ chemical after-filters such as the carbon absorber type that are capable of removing oil in both liquid droplet and super-heated phases. The solu- tion, however, is expensive and requires continuous maintenance and replacement of carbon filter cells.

Water removal

As the pressure of air is increased, its capability for holding moisture in suspension decreases. As the temperature of air increases, however, it is able to absorb much more moisture. If saturated air is compressed isothermally, therefore, the specific humidity will automatically be reduced. If the air is not initially saturated, isothermal compression will reduce the relative humidity of the air and it may well reach the saturation point during the compression process. Where air is compressed isothermally, therefore, quite large quantities of water vapour can be condensed, and in many cases the air leaving the compressor will be saturated. In adiabatic compression the temperature of the air will rise, and because of the marked ability of warmer air to support moisture, it is unlikely that any condensation will take place during the compression process.

Air line filters

As compression occurs very rapidly, it is quite possible that when condensation does occur, droplets of water will be carried through pipelines with the compressed air. Also, if additional cooling of saturated air occurs in the outlet line, further condensation will occur. The removal of droplets of water in suspension is a relatively simple process. Normal air line filters work on a similar principle to a spin drier. Air flowing through the filter is made to swirl by passing it through a series of louvers. This causes the water droplets to be thrown outwards and drain to a bowl where it can be drained off. It is important, therefore, that such filters, and compressor and air receiver drains, should be carefully maintained, and be protected from frost.

Air drying

If dry air is required for conveying a material a reduction in specific humidity can be obtained by cooling the air at constant pressure. This may be prior to compression or after. When air is cooled its relative humidity will increase, and when it reaches 100 per cent further cooling will cause condensation. Beyond this point the specific humidity will decrease. If the condensate is drained away and the air is then heated, its specific humidity will remain constant, but the relative humidity will decrease. This process is adopted in most refrigerant types of air dryer. Alternatively a desiccant dehumidifier can be used for the purpose. If the material to be conveyed is hygroscopic, some form of air drying is usually incorporated.

Refrigerants

Refrigeration drying is particularly effective when the air is warm and the humidity is high. Under these circumstances a cooling system can remove two to four times as much energy (temperature and moisture) from an air stream as the machine consumes in electrical power to accomplish this removal [1]. The air may be dried under atmospheric conditions, prior to being compressed or otherwise used, or it may be dried at pressure after it has been compressed. In the latter case refrigeration units are used for the dual purpose of both drying and cooling the air.

Refrigerant dryers usually have two stages of heat exchange. In the first the warm inlet air is pre-cooled by the cold, dry, outgoing air. It then passes to a refrigerant heat exchanger where it is cooled to the required dew point. This is usually about 2°C. Drying down to this level of moisture avoids problems of ice formation and freezing in the unit. If any further drying is required, much lower temperatures would have to be achieved, and this would make a refrigerant unit very expensive.

Such units, however, are now available and these have the capability of cooling the air down to -60°C. The process is generally staged, with three units arranged in series and parallel. The first is a conventional, continuously operating unit, which reduces the tem- perature to 2°C, as above. In series with this are two refrigeration units with the capability of cooling the air down to -60°C. As ice will form on these units they are arranged in parallel, with one operating, to dry the air, while the other is being de-frosted.

Desiccants

Desiccant dehumidifiers are particularly well suited to the removal of moisture from air at low temperature and low humidity. The driest possible air is obtained from a desiccant dryer. These are capable of reducing the moisture level to an equivalent dew point temperature of -70°C if necessary. They should not, however, be used for drying warm, humid air unless absolutely necessary, for they are costly to operate. A refrigeration system will generally add 10 per cent to the operating costs, but this may be as high as 30 per cent with a chemical type of dryer.

Typically 15 per cent of the compressed air being dried is lost to the system as it is required for purging the saturated desiccant in regenerative types. An additional problem with this type of system is that dust can be carried over into the conveying line. Water droplets often result in the bursting of the desiccant granules and so it is necessary to provide a filter for these fragments.

There are two main types of desiccant dryer. In one, desiccant tablets are charged, and when these decay they need to be topped up. In the other, a regenerative system is employed. For drying compressed air, two units operating in parallel are generally used. While the process air is passed through one unit for drying, the desiccant in the other unit is being dried by heated reactivation air ready for re-use. For the drying of atmospheric air a slowly rotating (typically at about six revolutions per hour) device is generally used in which the process and recirculation air streams are kept separate by means of seals.

It should be noted that this is entirely a chemical process, and although extremely low values of dew point can be achieved, there is no physical reduction in temperature of the air. The air temperature will rise in proportion to the amount of water removed [1]. For positive pressure conveying systems these are generally used to dry the air after it has been compressed and cooled.

The use of plant air

If plant air is available it may be possible to use this rather than purchase a separate compressor for the conveying system. If plant air is used it will certainly reduce the capital cost of the system, but careful consideration will have to be given to the oper- ating cost of this arrangement. If plant air is available at 6 or 7 bar, and the system only requires air at 1 or 2 bar, the cost of using plant air will be significantly higher than that from an air mover dedicated to the conveying system.

In the long term it may well be more economical to provide the system with its own air mover. If air is required at 2 bar gauge, for example, a given flow rate of air com- pressed to 7 bar gauge will require approximately 90 per cent more energy than com- pressing the same flow rate of air to 2 bar gauge.

Power requirements

Delivery pressure and volumetric flow rate are the two main factors that influence the power requirements of a compressor, blower or fan. For an accurate assessment of the power requirements, it will clearly be necessary to consult manufacturer’s literature. By this means different machines capable of meeting a given duty can be compared. For a quick, approximate assessment, to allow a comparison to be made of different operating variables, a simple model based on isothermal compression can be used:

where P is the power required (kW), V0 , the air flow rate at free air conditions (m3/s), m a, air mass flow rate (kg/s), p3, the compressor inlet pressure (bar abs) and p4, the compressor delivery pressure (bar abs).

This will give an approximate value of the actual drive power required. If this is multi- plied by the unit cost of electricity it will give the cost of operating the system. Since power requirements for pneumatic conveying can be very high, particularly if it is required to convey a material at a high flow rate over a long distance, this basic model will allow an estimation of the operating cost per tonne of material conveyed to be made.

To give some idea of the power required for the compressor, for a pneumatic conveying system, a graph is included in Figure 6.10 which shows how drive power is influenced by delivery pressure and volumetric flow rate.

Air pressures of up to 5 bar gauge are considered in Figure 6.10, and so will relate to high pressure systems, whether for dilute or dense phase conveying. Figure 6.11 is drawn and included specifically for dilute phase conveying systems, with delivery pressures appropriate to positive displacement blowers. A conveying line inlet air

velocity of 18 m/s has been considered and so the vertical axis has been drawn in terms of pipeline bore.

It must be emphasized that the models presented in Equations (6.5) and (6.6) are only for first approximation purposes.

The power required will vary from one type of compressor to another, and it will vary across the range of operating characteristics for each machine, such as those shown in Figures 6.5 and 6.6. For an accurate value, therefore, manufacturer’s literature must be consulted, as mentioned above, both for the type of compressor and the operating conditions.

In comparison with a reciprocating compressor, for example, a screw compressor would require approximately 10 per cent more power to provide the same volumetric flow rate at a given pressure. In the case of positive displacement blowers, the power requirements indicated on operating characteristics provided by manufacturers, such as those shown in Figures 6.5 and 6.6, do not always include transmission losses, etc. Values given are generally of absorbed power for the bare shaft only, and so filtration and transmission losses must be allowed for when selecting a motor.

Idling characteristics

All types of compressor are available in a wide range of models in order to cover the range of volumetric flow rates indicated on Figure 6.2. The upper limit on flow rate is clearly dictated by the size of the machine but the lower limit, for any given model, is not so clearly defined. For the blower shown in Figures 6.5 and 6.6 it will be seen that limits are provided in terms of a range of rotor speeds, and the turn down ratio, in terms of volumetric flow rate delivered for the particular model, is about 2:1 on volumetric flow rate.

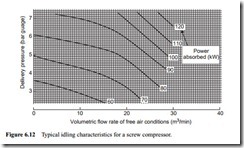

If a compressor is operated at a value of volumetric flow rate below its recom- mended lower limit, the efficiency of operation will fall. This will manifest itself by a marked change in the slope of the lines of constant power absorbed for the machine, such as those shown in Figures 6.5 and 6.6, at air flow rates below the lower operating limit. This is illustrated in Figure 6.12. These are operating curves for a screw compressor, which have been extended beyond the operating range for the machine, right down to zero flow rate, and hence idling conditions.

Compressors are often left to idle, when not required to deliver air, so that they do not have to be re-started, and so are instantly available for use when required. It will be seen from Figure 6.12, however, that there is a significant penalty to pay in terms of power required for this operating stand-by duty. Due to the change in slope of the lines

of constant power absorbed, below the recommended range of operating, the power absorbed when idling, and delivering no air, is almost 70 per cent of that required for full load operation. Thus when idling, at a given delivery pressure, there is a saving in power of only some 30 per cent.