HYDRAULIC PUMPS

The purpose of a hydraulic pump is to supply the flow of fluid required by a hydraulic system. The pump does not create system pressure. System pressure is created by a combination of the flow generated by the pump and the resistance to flow created by friction and restrictions within the system.

As the pump provides flow, it transmits a force to the fluid. When the flow encounters resistance, this force is changed into pressure. Resistance to flow is the result of a restriction or obstruction in the flow path. This restriction is normally the work accomplished by the hydraulic system, but there can also be restrictions created by the lines, fittings, or components within the system. Thus, the load imposed on the system or the action of a pressure-regulating valve controls the system pressure.

OPERATION

A pump must have a continuous supply of fluid available to its inlet port before it can supply fluid to the system. As the pump forces fluid through the outlet port, a partial vacuum or low-pressure area is created at the inlet port. When the pressure at the inlet port of the pump is lower than the atmospheric pressure, the atmospheric pressure act ing on the fluid in the reservoir must force the fluid into the pump’s inlet. This is called a suction lift condition.

PERFORMANCE

Pumps are normally rated by their volumetric output and discharge pressure. Volu metric output is the amount of fluid a pump can deliver to its outlet port in a certain period of time and at a given speed. Volumetric output is usually expressed in gallons per minute (gpm).

Since changes in pump speed affect volumetric output, some pumps are rated by their displacement. Pump displacement is the amount of fluid the pump can deliver per cycle or complete rotation. Since most pumps use a rotary drive, displacement is usually expressed in terms of cubic inches per revolution.

Although pumps do not directly create pressure, the system pressure created by the restrictions or work performed by the system has a direct effect on the volumetric out put of the pump. As the system pressure increases, the volumetric output of the pump decreases. This drop in volumetric output is the result of an increase in the amount of leakage within the pump. This leakage is referred to as pump slippage or slip. It is a factor that must be considered in all hydraulic pumps.

PUMP RATINGS

Pumps are generally rated by their maximum operating pressure capability and their output in gallons per minute (gpm) at a given operating speed.

Pressure

Based on reasonable service life expectancy under specified operating conditions, the manufacturer determines the pressure rating of a pump. It is important to note that there is no standard industry-wide safety factor in this rating. Operating at higher pressure may result in reduced pump life or more serious damage.

Displacement

The flow capacity of a pump can be expressed as its displacement per revolution or by its output in gallons per minute (gpm). Displacement is the volume of liquid trans ferred in one complete cycle of pump operation. It is equal to the volume of one pumping chamber multiplied by the number of chambers that pass the outlet during one complete revolution or cycle. Displacement is expressed in cubic inches per revolution.

Most pumps that are used in hydraulic applications have a fixed displacement, which cannot be changed except by replacing certain components. However, in some it is possible to vary the size of the pumping chamber and thereby the displacement by means of external controls. Some unbalanced vane pumps and many piston units can be varied from maximum to zero delivery or even to reverse flow without modification to the pump’s internal configuration.

Volumetric Efficiency

In theory, a pump delivers an amount of fluid equal to its displacement each cycle or revolution. In reality, the actual output is reduced because of internal leakage or slip page. As pressure increases, the leakage from the outlet to the inlet or to the drain also increases and the volumetric efficiency decreases.

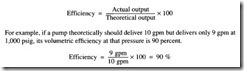

Volumetric efficiency is equal to the actual output divided by the theoretical output. It is expressed as a percentage:

If the discharge pressure is increased, the amount of slippage will increase. If we increase the pressure in the preceding example to 1,500 psig, the actual output may drop to 8 gpm. Therefore, the volumetric efficiency will decrease to 80 percent at 1,500 psig.

PUMP CLASSIFICATIONS

Many different methods are used to classify pumps. Terms such as hydrodynamic, positive-displacement, fixed-displacement, variable-displacement, constant-volume, and others are used to describe hydraulic pumps.

Positive-displacement pumps, unlike centrifugal pumps, will provide a definite volume of fluid for each cycle of pump operation, regardless of the resistance offered by the system, provided the capacity of the power unit driving the pump is not exceeded. If the outlet of a positive-displacement pump were completely closed, the pressure would instantaneously increase to the point at which the pump driver would stall or something in the drive-train would break.

Positive-displacement pump classification can be subdivided into other classifications that include fixed-displacement or variable-displacement. Other terms, such as fixed-delivery, constant-delivery, and constant-volume, may be used to describe this type of pump.

The fixed-displacement pump delivers the same amount of fluid on each cycle. Only changing the speed of the pump can change the output volume. When a pump of this type is used in a hydraulic system, a pressure regulator or relief valve must be installed in the system.

The variable-displacement classification of hydraulic pumps is constructed so that the displacement per cycle can be varied. The displacement is varied through the use of an internal control device. The construction of these devices can vary from an unloading or pressure regulating valve to restricted-flow bypass loops. Some of these devices will be described in the control valve section.

Hydraulic pumps may also be classified according to the specific design used to create the flow of fluids. Practically all hydraulic pumps fall within three design classifications: centrifugal, rotary, and reciprocating. The use of centrifugal pumps in hydraulics is extremely limited and will not be discussed in this text.