Specific energy

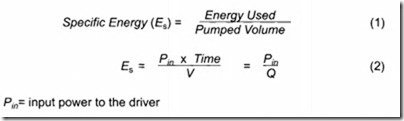

A useful measure for calculating the cost of pumping is the specific energy E5• Specific energy is measured as kWh/m3, where kW = power in kilowatts, h = time in hours, and m3 = volume in cubic metres. Specific energy is also a useful measure for comparing different system solutions.

In systems where the flow is constant, this is a simple task by using the equations below. In systems with varying flow rates, it becomes a little more complicated, because each duty must be separately calculated and summated to obtain total costs.

First, E5 needs to be calculated as a function of flow rate. This requires information from pump, motor and drive manufacturers. The pump manu facturer has to provide pump curves for variable speed operation while the motor and drive suppliers have to provide efficiency curves as a function of load and speed.

When E8 has been calculated this information needs to be combined with the duration diagram in order to obtain the total operational cost. The designer can then compare systems with different numbers of pumps as well as different methods of regulation.

Es is a function of flow rate (Q). It is, therefore, necessary to evaluate this dependence. (This is especially important when a variable speed drive is contemplated in order to avoid pitfalls.)

It is useful to separate systems with and without static head since they have different characteristics.