Mining and quarrying equipment

Many of the tools described under Contractor’s Tools are also employed in mining and quarrying, although the emphasis in modern mining is towards the removal and processing oflarge quantities of rock, for which high powered drilling rigs are required. The principle of rock drilling is the same, whether a hand-held drill or a multi-head drilling rig is used. Mining is one area where hydraulic drills are offering a real challenge to the former superiority of pneumatic drills because, when the emphasis is on maximising drilling speed, hydraulic power comes into its own. However, a great deal of mining is still done using compressed air for the drilling process, sometimes combined with hydraulic power for support of the drills and for applying feed and rotation forces.

Hand-held rock drills

The small sinker drills discussed in the chapter on Contractor’s Tools are occasionally used in mines and quarries, mainly for work such as drilling for secondary blasting. Two other tools, used in considerable numbers are air-leg drills and stopers. These two drills were first used as a stage in the development towards the modem powered support; they take out some of the physical effort that was formerly needed when using a simple sinker drill.

Air-leg or pusher leg drills

An example of a drill of this kind is shown in Figure I. The drill as shown is basically a standard sinker drill, without the handles and supported by a pneumatic cylinder which, under pressure, is able to support the weight of the rock drill and supply the feed thrust for drilling. The support leg is hinged to the drill body, so there can be any chosen angle between the drill axis and the leg. This drill is used primarily for tunnelling and mine development purposes.

Figure I shows the drill in a rather ideal geometric arrangement, where, if the correct pressure is supplied to the leg, the feed force, weight and leg force are in balance. In practice, the geometry changes considerably during the drilling of the round, so that for some of the time the ideal balance cannot be achieved without the operator applying an

extra manual load. When the hole has advanced some distance into the rock, the drill rod itself can give some extra support by bearing against the sideofthe hole. However, friction against the sides of the hole slows down the rotation and reduces the drilling speed. This kind of drilling requires constant attention from the operator, and also requires a great deal of hard physical effort; in modem, large scale mining and tunnelling it has been largely superseded by techniques using support rigs.

The drill shown is of integrated design, which means that all the controls for drilling and for supplying air to the leg are incorporated in the backhead of the drill. Air passes from the backhead control via passages in the hinge pin to the cylinder. The operator is able to select feed or retract and adjust the feed force from the one control tumbler.

Note that two hoses supply the drill: the larger is for delivering the compressed air; the smaller is for the flushing water, which passes down through the centre of the drill and washes out the rock chippings. Water, rather than air, is universally used for flushing in underground drilling. Ithas been found that air flushing causes harmful dust to be released into the air, which in the past has been responsible for crippling lung diseases such as silicosis.

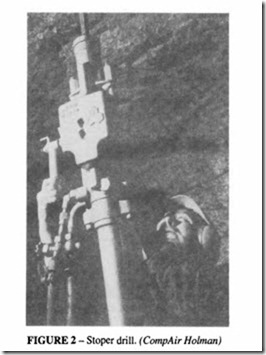

Stoper drills

An example of a stoper is shown in Figure 2. This is very similar to the air-leg drill, except that it is designed for overhead work in a stope (a chamber formed for excavating ore) or for drilling a raise (a shaft excavated upwards). The support leg is rigidly attached to the body of the drill and controlled in a similar way to the air-leg drill.

A stoper is also employed for roofbolting (a technique for strengthening a roof in a mine stope by bolting it back into sound rock with long bolts). A stoper intended for rock bolting

can be supplied with a clockwise rotation, rather than the more usual anti-clockwise rotation mechanism so that, as well as drilling the hole, it can also tighten the nuts.

Rig mounted drills

Rig mounted pneumatic drills, operating on very much the same principle as the hand-held drills described above are available for underground and surface work.

In recent years, there has been a tendency to move from pneumatic to hydraulic drilling, since hydraulic operation is much more efficient in terms of energy consumption. However, the hydraulic drill is more of a precision tool requiring a higher level of maintenance and the initial cost is higher. The majority of hard rock drilling is still done by pneumatic drills.

Figure 3 shows three drills suitable for this kind of work. In this type of drill the rotation is obtained by a separate rotation motor, which is usually of the meshing gear type. This makes it possible to generate a much higher torque than with the rifle bar rotation discussed in the chapter on Contractor’s Tools. The rotation may be separately controlled in speed and direction to meet a variety of drilling conditions. There is also a separate supply of air or water for flushing the hole.

The drill is capable of drilling 100 mm diameter holes several metres in length. The drilling speed depends upon the type of rock drilled and to some extent on the length of

the hole. There is always some drop in performance as the length of the drill rod increases. Some of the energy is converted into heat in the material of the drill rod and there are losses at the screwed couplings.

For underground drilling, water flushing is employed to clear out the drill chippings, but for surface drilling, air flushing is more usual. The flushing medium (air or water) passes through a flushing tube situated along the centre line of the drill.

Drilling rigs for underground operations

Support rigs can be comparatively simple as shown in Figure 4, which is a small twin-drill unit on a rubber-tyred base. The motive power is diesel engine, fitted with an exhaust scrubber. This rig incorporates a degree of automatic control on the hole alignment and on the drill control stop and start. One man can easily operate two drills, without any great physical effort.

Large mining operations tend to use multi-drill rigs called jumbos. A jumbo consists of several pneumatic (or hydraulic) drills mounted on a support structure which allows each

drill to be separately controlled from a single operating position. The feed force and the mechanism for positioning the drill at the rock face are usually hydraulically powered. The jumbo itself may be mounted on tyred wheels or on crawler tracks and is self-propelled. The motive power can come from an electric power unit or from an internal combustion engine mounted on the jumbo base. Percussion can be pneumatic (although it has to be admitted that hydraulic is increasingly taking over), with the rotation power coming from a separate pneumatic or hydraulic motor.

With an increasing trend towards automation, control systems for thesejumbos become increasingly complex:

• Feed and rotation power can be monitored and separately controlled to maximise the drilling speed.

• The angular inclination of the holes can be controlled, either for parallel drilling or for a pre-set angle to the tunnel axis.

• A drilling pattern can be programmed into the control unit so that the drill moves automatically from hole to hole to give an ideal blasting pattern.

Quarrying equipment

The drilling regime in a quarry or open pit mine is very different from that in an underground mine, and the drills used reflect that difference. A quarry is required to produce a high volume of rock, produced in “benches” or steps on the vertical (or slightly off the vertical) face of the quarry. The height of these benches can be of the order of 20 m or more, and the diameter of the drilled hole is between 75 mm and 150 mm. With modern equipment it is possible to drill 250m per man per shift.

In the early quarries, much of the drilling was done with hand-held drills, able to penetrate no more than about 2- 3 m. Gradually, with the introduction of more powerful rig supported machines and the use of coupled drill rods, the hole depth increased; but it was soon discovered that, when drilling long holes, much of the impact energy was dissipated during its transmission down the rods and through the screwed couplings.

This led to the placing of the drill down the hole close to the bit so that the wastage of energy was reduced.

Method of Operation

The non-return valve ensures that air is trapped in the hammer when the tubes are disconnected, so preventing water and dirt entering via the drill bit.

The bit is locked in by the retaining ring and is released by unscrewing the chuck.

Air enters the tube adaptor at the top of the hammer, passes the non-return valve and is directed into the annulus around the cylinder liner. Air is then directed to each side of the piston by a series of ports, uncovered as the piston moves down the cylinder. Exhaust is controlled by the control post; the exhaust point is reached when the piston passes the end of the control post, allowing the air from the upper chamberto pass through the central hole ofthe piston and the bit and emerge at the rock face. The return stroke 13 exhaust is controlled by a foot valve which is part of the bit; exhaust point is reached when the striking face of the piston 14 uncovers the end of the foot valve, allowing air to pass through the bit as before.

Extra air can be passed continuously through the ham 15 mer to improve hole flushing; this is achieved by drilling a hole in the constant blowing plug, allowing a supply of air to 16 pass directly to the bit, bypassing the power chambers.

The hole can be flushed by lifting the hammer off the bottom of the hole, allowing the bit to drop down against the retaining ring. Air then passes from the return chamber, past 17 the bit splines, which causes the hammering to stop.

The hammer can be supplied with a shock absorber between the tube adaptor and the first tube. This helps to protect the drill tubes and the rotation motor from the reaction forces of drilling.

FIGURE 5- Components of down-the-hole hammer. (CompAir Holman) These “down-the-hole” drills are designed to produce maximum impact energy in a small diameter body. They have a smooth exterior profile, the bit is locked into the front of the drill, and the rotation is obtained from an external motor connected to the bit by coupled tubes. Because there is no loss of impact energy there is virtually no limit to the hole depth (other than that caused by practical limitations such as tube handling). These drills are universally used for drilling long holes on thesurfaceand, in limited applications, underground. The tubes that support the drill also act as a passage for the compressed air which, after use, is exhausted through the drill bit and is then able to flush away the drill chippings. Such a drill is shown in cross-section in Figure 5.

The drill illustrated is available for bit diameters of 75 to 150 mm and is typical of modern valveless hammers – valveless because air distribution to power and return chambers is achieved by piston position rather than by a distributor valve. Both valved and valveless hammers are available. The valveless type is more favoured for modern drills for two main reasons: they are less subject to clogging by dirt and they are more efficient because the air is used expansively. But different drilling situations require different hammers, so one’s choice should be based on a practical drilling trial in the quarry for which it is intended. It will be apparent that the diameter of the hammer, being less than the hole size, is the main factor limiting the design. The impact energy is proportional to piston diameter, stroke length and air pressure; so with the diameter limited, the energy can only be increased by increasing the pressure. Down-the-hole hammers are designed to operate on pressures between I 0 and 25 bar for which special high pressure portable compressors are needed.

Support rigs for quarry drills

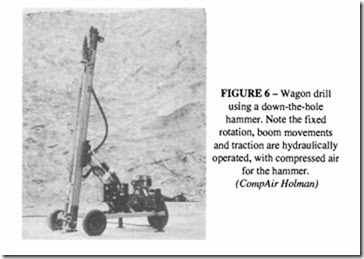

Choice of a suitable rig for supporting a drill depends on the throughput of the quarry, particularly the number and size of the blast holes. For a small quarry limited by size and environmental considerations, the appropriate hole size will be 75 or 100 mm diameter, and a small wagon drill (such as shown in Figure 6) might be appropriate. The drill illustrated is a pneumatic integral rotation drill, with coupled rods. Feed force is supplied by a pneumatic motor driving a chain feed. This rig can also be used for small down-the hole drilling. This support rig can be equipped with an hydraulic boom for elevating the cradle. Some models can be made self-propelled by mounting a motor on one of the wheels, otherwise it has to be towed from hole to hole by a tractor. The compressor also has to be towed into position.

A more advanced kind of rig is shown in Figure 7; this is a self-propelled tracked vehicle, with the control grouped at a central location. It is shown supporting a down-the hole drill.

Hole flushing

Good hole flushing is important for removal of the drilling detritus, and can be done either by air or water. Water is customary for underground drilling, where the dust has to be suppressed, but on surface workings where a reliable source of water is not available, dry flushing with compressed air is usual.

With down-the-hole hammers, the exhaust air plays an important role in hole flushing and in most cases is sufficient in quantity for complete flushing, but there is a provision for adding to the volume by incorporating an extra flushing hole, as shown in Figure 5. Most manufacturers of drills recommend a compressor with a capacity about 25% higher than the minimum needed to operate the drill, to allow for extra flushing air. The amount of air required depends on the size of the hole and the diameter of the hammer and rods. After the air has lifted the chippings off the drill face, it is fully expanded and then has to transport the chippings out of the hole. The velocity of the air should be about 30 rnls, calculated from the known volume per second and the annular area between the rods and the hole. If the ground is very wet, with water pouring into the hole from fissures in the rock, the velocity may have to be increased. In good conditions, in hard rock, a lower velocity may be adequate. Too high a velocity is wasteful of air and accelerates the wear of the drill and rods through a “sand-blasting” effect; too low a velocity reduces drilling speed and may cause jamming of the rods.

With water flushing the velocity should be about I rnls.

Foam flushing is also used occasionally. It is basically air flushing with the addition of a foaming agent injected into the air inlet. It assists in suppressing dust and lubricating the wall of the hole. It can be a useful technique where dust is a problem and where a dust collector is not suitable.

Dust collectors

A large amount of drilling dust is produced by a high performance drill. Apart from being a health hazard, it is a nuisance to the drill operator and can reduce site safety. Dust collectors have a suction hood which is positioned around the drilled hole to suck away all the dust emitted. The suction is produced either by an air powered ejector or a fan. The dust is carried away through a large diameter hose to the separation equipment which is in two stages. The first stage is a cyclone separator to remove the large particles and the second stage is a filter, which removes the remaining fine dust. Some designs have automatic filter cleaning which comes into action every time the drilling stops; others have to be cleaned after every hole, or when necessary.