HYDRAULIC FLUIDS

Selection and care of the hydraulic fluid for a machine will have an important effect on how it performs and on the life of the hydraulic components. During the design of equipment that requires fluid power, many factors are considered in selecting the type of system to be used-hydraulic, pneumatic, or a combination of the two. Some of the factors required are speed and accuracy of operation, surrounding atmospheric conditions, economic conditions, availability of replacement fluid, required pressure level, operating temperature range, contamination possibilities, cost of transmission lines, limitations of the equipment, lubricity, safety to the operators, and expected service life of the equipment.

After the type of system has been selected, many of these same factors must be con sidered in selecting the fluid for the system. This chapter is devoted to hydraulic flu ids. Included in it are sections on the properties and characteristics desired of hydraulic fluids; types of hydraulic fluids; hazards and safety precautions for working with, handling, and disposing of hydraulic liquids; types and control of contamina tion; and sampling.

PURPOSE OF THE HYDRAULIC FLUID

As a power transmission medium, the fluid must flow easily through lines and compo nent passages. Too much resistance to flow creates considerable power loss. The fluid also must be as incompressible as possible so that action is instantaneous when the pump is started or a valve shifts.

Lubrication

In most hydraulic components, the hydraulic fluid provides internal lubrication. Pump elements and other wear parts slide against each other on a film of fluid (Figure 4-1).

For long component life, the oil must contain the necessary additives to ensure high anti-wear characteristics. Not all hydraulic oils contain these additives.

Sealing

In many applications, hydraulic fluid is the only seal against pressure inside system components. In Figure 4-1, there is no seal ring between the valve spool and body to prevent leakage from the high-pressure passage to the low-pressure passage. The close mechanical fit and viscosity of the hydraulic fluid determine leakage rate.

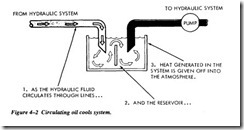

Cooling

Circulation of the hydraulic oil through lines, heat exchangers, and the walls of the reservoir (Figure 4-2) gives up heat that is generated within the system. Without this

cooling, the heat generated by the hydraulic pump and mechanical work performed by system actuators would build to a point that damage of system components could cause premature failure of the system.

PROPERTIES OF HYDRAULIC FLUID

If fluidity-the physical property of a substance that enables it to flow-and incompressibility were the only properties required, any liquid that is not too thick might be used in a hydraulic system. However, a satisfactory liquid for a particular system must possess a number of other properties. The most important properties and some charac teristics are discussed in the following paragraphs.