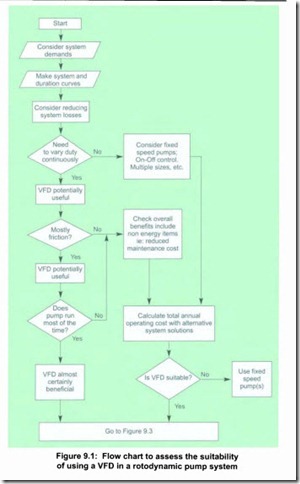

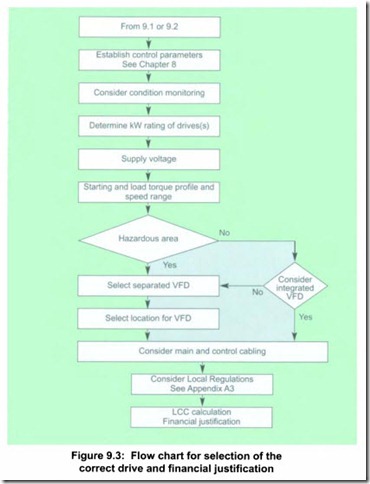

Flow charts

Flow charts to assess the suitability of a VSD for a pump system are shown in Figures 9.1 for rotodynamic pumps and 9.2 for positive displacement

pumps. These are based on using a variable frequency drive, which will be more efficient than any speed control device, which uses slip to vary the speed. Having established that using a VFD is appropriate, Figure 9.3 is a flow chart for selecting the correct drive and making the life cycle cost calculation. Chapter 12 will help in making the financial justification.

Appendix A2.4 contains information on the factors to be considered in sizing a drive.

Related posts:

Applied Pneumatics:Automation and robotics

Valves and Sensors:Air flow measurement

Valves and Sensors:Control valves

Air only relationships:Stepped pipelines and Air only pressure drop.

Erosive wear:Data sources and Issues considered.

Pressure and flow:Pascal's law.

Control components in a hydraulic system:Flovvrneters.

ACTUATORS:CONVERTING SCFM INTO COMPRESSOR HORSEPOWER

ROUBLESHOOTING HYDRAULIC SYSTEMS:FAILURE MODES OF HYDRAULIC COMPONENTS

RESERVOIRS, STRAINERS, FILTERS, AND ACCUMULATORS:Diaphragm Accumulators.

Control Valves:types of control valve

SUMMARY OF BASICCONCEPTS OF THE RMODYNAMICS

THE FIRST LAW OF THERMODYNAMICS:SOME STEADY-FLOW ENGINEERING DEVICES

POWER AND REFRIGER A TION CYCLES:THE IDEAL VAPOR-COMPRESSION REFRIGERATION CYCLE

NATURAL CONVECTION:EQUATION OF MOTION AND THE GRASHOF NUMBER