Explosion protection

Despite the fact that the potential for an explosion in a pneumatic conveying system is high, the demand for such systems also remains high. This is partly due to the fact that the system totally encloses the material, such that dust generation external to the sys- tem is virtually eliminated, and with a pipeline total flexibility in the conveying route is possible without material transfer or staging. There are also a number of different means by which a pneumatic conveying system can quite easily be protected.

Since the dispersion of powdered and granular materials in air is fundamental to pneumatic conveying, it is evident that if a material is known or shown to be explosible, then consideration should be given to the hazard that this presents at the design stage of a system, or when re-commissioning an existing system to convey a different material. While it is equally obvious that the generation of sources of ignition should be minimized, unforeseen mechanical, electrical or human failures mean that the complete elimination of ignition sources cannot be relied upon, particularly where powered machinery is involved.

To avoid the potentially catastrophic effects of an explosion, therefore, reliance is normally placed on the adequate functioning of a means of protection for the system. Such protection is normally based on one or more of the following approaches:

1. Minimizing sources of ignition and prevention of ignition.

2. Allowing the explosion to take its full course but ensuring that it does so safely by either containment or explosion relief venting.

3. Detection and suppression.

The method of protection selected will depend upon a number of factors. These include the design of any associated plant or process, the running costs, the economics of alternative protection methods, the explosibility of the material, and the extent to which an explosion and its consequences can be foreseen, together with the requirements of any local regulatory authorities concerned.

Minimizing sources and prevention of ignition

The first step in any explosion protection programme is to minimize or eliminate, as far as possible, all potential sources of ignition. The minimum ignition temperature is relevant to ignition by hot surfaces. Rotary valve bearings have already been mentioned in this context, as an example, and welding operations on any part of the system should be prohibited while the system is operating. The possibility of sparks must also be reviewed, with due consideration given to valve operations, friction with conveyed materials, and electrostatic generation.

Inerting

Prevention of ignition can be guaranteed by using an inert gas such as nitrogen for conveying the material. Alternatively, nitrogen can be added to the air in order to reduce the percentage of oxygen present in the conveying air to a level at which a flame cannot be supported. The maximum oxygen concentration is one of the many standard tests that can be carried out with a material, as mentioned earlier. Since inert gases are rather expensive, these methods are generally used with closed loop systems (see Figure 26.2).

Containment

The combustion of a dust cloud will result in either a rapid build up of pressure or in an uncontrolled expansion. It is the expansion effect, or the pressure rise if the expansion is restricted, that presents one of the main hazards in dust explosions. The expansion effects arise principally because of the heat generated in the combustion and, in some cases, to gases being evolved from the dust because of the high temperature to which it has been exposed.

If the presence of evolved gases is neglected, the situation can be modelled very approximately with the thermodynamic relationship (see Section 9.2.3):

Flame temperatures are typically a couple of thousand degrees and so it can be seen that explosion pressures can reach 7 or 8 bar. The critical information from Table 26.2, however, is that this pressure can be reached in milliseconds.

When a dust explosion occurs in industrial plant spectacular destruction can result if it is initially confined in a system that is ultimately too weak to withstand the full force of the explosion. Blow tanks and rotary valves, however, can be obtained that will withstand these pressures and in a positive pressure system the compressor or blower can be protected by means of a non-return valve in the air supply line. Most pipelines are also capable of withstanding this order of pressure.

If this is so, the resulting pressure wave would pass along the pipeline and be relieved at the weakest point, which is usually the reception vessel. Due to their size these are generally only capable of withstanding very low pressures, as mentioned earl- ier, and so if exposed to a higher internal pressure they would probably rupture or burst. Consequently the collection unit is likely to be the most vulnerable part of the system. It is unlikely to be an economic proposition to design the reception vessel to withstand the explosion pressure. There are, however, alternative means of protecting the receiving vessel.

Explosion relief venting

The usual solution to the problem in situations where the risk of an explosion is only very slight is to allow an explosion to take its full course, while employing suitable precautions to ensure that it does so in a safe manner. As an alternative to containment, the reception vessel can be fitted with appropriate relief venting. This may take the form of bursting panels, displacement panels or hinged doors that operate once a pre- determined pressure has been reached.

In venting explosions to atmosphere strict attention must be paid to the safe dissipation of the explosion products. It is a characteristic that the volume of flame dis- charged from vents can be very large, and obviously must be directed to a safe place away from operatives and neighbouring plant. If this is necessary it is normally achieved by attaching a length of ducting to the vent, or by installing deflector plates. The duct attached to the vent should be short, free from bends (if at all possible) and other restrictions to flow, and be kept clear of dust at all times.

The size of duct, in terms of flow cross-section area, for explosion venting is par- ticularly important. This is related to the maximum rate of pressure rise and the more vigorously explosible materials require larger areas of venting. The size of vent is also dependent upon the volume of the receiving hopper or silo. This situation can also be modelled very approximately from the above thermodynamic relationship. If the explosion is to be vented to prevent a pressure rise, p1 will now be approximately equal to p2, but V1 will no longer equal V2. Thus:

and hence the volumetric flow rate of the gases now leaving the reception vessel will be about seven times higher than normal, and this does not take account of gases generated as a result of the explosion. There will be no possibility of the existing filter plant being able to cope with this increased flow rate and so venting is essential.

To keep the pressure drop in the explosion relief ducting to as low a value as possible, the duct will have to be of a large section area. Since pressure drop varies approximately with the square of velocity, the velocity of the gases in the ducting will have to be very much lower than that of the incoming conveying air. Combined with the sevenfold increase in steady state flow rate, and the fact that this is a transient situation, duct sizing is a complex task and should only be assessed by an expert.

Detection and suppression

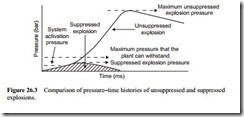

If a system is inconveniently sited to allow for venting; a vent of the required size can- not be fitted onto the existing hopper; or if the material is toxic, so that it cannot be freely discharged to atmosphere, the protection may be achieved by a detection and suppression approach. Although there may be only a few tens of milliseconds between the ignition of the material to the build up of pressure to destructive proportions, this is sufficient for an automatic suppression system to operate effectively, as illustrated in Figure 26.3.

Commercial equipment is available that is capable of both detecting the onset of an explosion and of suppressing the explosion before it is able to develop. The sensing device, on detecting a rise in pressure, can send signals to switch off the air supply and stop the feeding device in order to prevent the conveying of any further material. A signal can also be sent to operate the automatic opening of a venting system. An automated opening has the advantage that vents are opened extremely rapidly and for very explosible materials this helps to reduce the maximum explosion pressure. Alternatively a suppressant system can be triggered. Such equipment operates as illustrated in Figure 26.4.

Suppression involves the discharge of a suitable agent into the system within which the explosion is developing. The composition of the agent depends upon the material being conveyed, and is typically a halogenated hydrocarbon, or an inert gas or powder. The suppressant is contained in a sealed receptacle attached to the plant and is rapidly discharged into the system by means of an electrically fired detonator or a controlled explosive charge. Thus, as soon as the existence of an explosion is detected, the con- trol mechanism fires the suppressant into the plant and the flame is extinguished.

Alternatively the explosion can be automatically vented. When the explosion is detected a vent closure is ruptured automatically, thus providing a rapid opening of the vent. The vented explosion then proceeds as for cases in which the vents are opened by the pressure of the explosion. Since it is obvious that once an explosion has been initiated, no more material should be fed into the system, plant shut-down can also be rapidly achieved with the detector approach.

Secondary explosions

With positive pressure conveying systems there is always the possibility of a failure or defect in the system resulting in the discharge of a dust cloud into the atmosphere. Abrasive materials wearing holes in pipeline bends and neglecting to tighten pipeline couplings have already been mentioned. Filters can also represent a weak link. A pressure surge from a blow tank, or supplementary air from an air receiver on purging a pipeline, may result in the release of dust, or even the failure of a filter element. A flammable dust cloud can be produced quite accidentally in many different circumstances.

There must, therefore, be no possible sources of ignition external to the system. One of the major sources of ignition in this situation comes from electrical equipment. If the material being conveyed is potentially explosive, therefore, it is essential that all the lighting, switches and switchgear, contacts and fuses, and electrical equipment in the vicinity, or within the same building, should be of a standard or class that would not be able to provide a source of ignition, whether a spark or hot surface. It is equally important that good housekeeping is maintained at all times within the same area, such that any dust release is not allowed to accumulate on any surfaces anywhere, and on lighting and electrical equipment in particular.

The release of a dust explosion from a conveying system into a building, or the explosion of a dust cloud released from a conveying system inside a building, are both clearly very serious situations. Little hazardous pressure is likely to develop from either of these sources of explosion within a large building, if short-lived, but the pres- sure wave generated usually shakes down more dust which has settled over a period of time onto pipe-work, roof beams and supports, ledges, lighting, etc. This then makes

Material sample Explosion characteristics Relevant hazard or

an ideal condition for the secondary explosion that almost always follows. It is this secondary explosion that can demolish a factory and kill the operatives.

Determination of explosion parameters

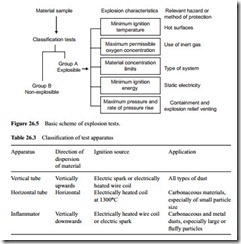

In the UK all tests concerned with assessing the explosibility or measurement of explosion characteristics of materials in suspension are methods agreed with HM Factory Inspectorate, and are carried out in the sequence shown in Figure 26.5.

As a result of this established procedure, data regarding the explosion characteristics of many materials already exists [1, 7–9]. With a material that has not been previously tested, the first step should be to determine whether it is potentially explosive. The outcome of such a test will then indicate the necessity of incorporating precautionary measures into the system design. In the UK, explosibility tests were conducted on an official basis by the Fire Research Station, with apparatus of the type summarized in Table 26.3.

Test apparatus

In the vertical tube apparatus the dust is placed in a cup and dispersed upwards over the ignition source by a controlled air blast. Observation of the flame propagation can then be made. A modification of the electrodes will allow this device to be used for the determination of minimum ignition energy. The Hartmann bomb is a more substantial version of this apparatus that can also be used for the measurement of explosion pres- sure and rate of pressure rise [10].

The horizontal tube apparatus also involves the dispersion by air of a dust sample over an ignition source. Since the residence time of a dust near the coil is short, any material that is observed to propagate a flame must be regarded as presenting a ser- ious explosion hazard. The inflammator is essentially a vertically mounted glass tube. A sample of dust, held in a horizontal tube, is blown by air and is directed downwards by a deflector plate.

Although convenient for the testing of explosion characteristics, the Hartmann bomb has been criticized on the grounds that test results do not reliably scale up to correspond to industrial plant. This has led to the development of the so-called 20-l sphere apparatus. This consists of a spherical stainless steel vessel fitted with a water jacket. A dust cloud is formed in the vessel as the dust enters from a pressurized chamber through a perforated dispersion ring. Sixty milliseconds after the dust is released into the sphere the detonator is fired and the resulting pressure rise is monitored [10].

Material classification

Depending on the outcome of such tests the material is simply classified with respect to explosibility as follows:

• Group A – materials which ignited and propagated a flame in the test apparatus.

• Group B – materials which did not propagate a flame in the test apparatus.

Group A materials clearly represent a direct explosion risk and, as such, it would be a wise precaution, or even a legal requirement, to incorporate protection measures into the system. The range of materials that fall into this group is wide, as indicated earlier. Sand, alumina and certain paint pigments are examples of Group B materials. Some Group B materials, although not explosible, may nevertheless present a fire risk. Further details regarding materials that have been categorized with respect to this A and B classification may be obtained from [11].

If a material is shown to be of the Group A type, further information on the extent of the explosion hazard may be required when considering suitable precautions for its safe handling. The following parameters can be determined by use of the test methods described above:

1. minimum ignition temperature,

2. maximum permissible oxygen concentration to prevent ignition,

3. minimum explosible concentration,

4. minimum ignition energy,

5. maximum explosion pressure and rate of pressure rise.

Since the explosion characteristics, in terms of these parameters, of many materials are well documented elsewhere [7–9], it is not appropriate to include this information here. In order to illustrate the magnitude of the quantities involved, however, details regarding a few well known materials are given in Table 26.2 [7]. A summary of the applications of the results of these various tests to practical conditions is included in Figure 26.5.