Dust control

In addition to the economic reasons for efficiently removing solid material from a conveying gas stream, there are important considerations of product quality control, and health and safety. In this respect it is generally very fine particles or dust that pose the problem.

Particle degradation

In some manufacturing processes, a bulk solid is actually required in the form of ultra- fine particles. In many cases, however, the presence of dust in the product is undesirable for practical and commercial reasons. Much of the dust results from particle degradation in the conveying process and, for a given material, this is a function of the conveying conditions, in terms of material concentration and conveying air velocity, and the pipeline geometry.

Plant operating difficulties can result if degradation causes a large percentage of fines to be produced, particularly if the filtration equipment provided is not capable of handling the fines satisfactorily. Filter cloths and screens will rapidly block if they have to cope with unexpectedly high flow rates of fine material. The net result is that there is usually an increase in pressure drop across the filter.

This means that the pressure drop available for conveying the material will be reduced, which in turn means that the mass flow rate of the material will probably have to drop to compensate. Alternatively, if the filtration plant is correctly specified, with particle degradation taken into account, it is likely to cost more as a result. This, therefore,

provides a direct financial incentive to ensure that particle degradation is minimized, even if it is not a problem with respect to the material itself.

Dust emission

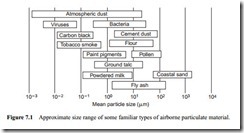

Excepting the potentially explosive and known toxic materials, the most undesirable dusts are those that are so fine that they present a health hazard by remaining suspended in the air for long periods of time. Figure 7.1 illustrates comparative size ranges of some familiar airborne particles. Airborne dusts which may be encountered in industrial situations are generally less than about 10 J..m in size.

Particles of this size can be taken into the body by ingestion, skin absorption or inhalation. The former is rarely a serious problem and, although diseases of the skin are not an infrequent occurrence, it is inhalation that presents the greatest hazard for workers in a dusty environment.

Particles falling in the size range of approximately 0.5–5 J..m, if inhaled, can reach the lower regions of the lungs where they will be retained, and prolonged exposure to such dusts can cause permanent damage to the lung tissues (pneumoconiosis) symptomized by shortness of breath and increased susceptibility to respiratory infection. Prevention of the emission of these fine particles into the atmosphere is thus of paramount importance, whether they have been proven to be problematical or not.