Carbon dioxide

This is naturally present in the atmosphere in various concentrations depending on the environment and may be tolerated at much higher levels than the CO, but will impair psychomotor functions if the levels are high. It is readily removed by a variety of desiccants, both adsorptive and absorptive, with the absorptive type predominating. These materials have a limited capacity and therefore need replacing or reactivating at regular intervals.

Nitrous oxide and nitrogen oxide

These are present in the air as effluents of industrial processes and by combustion within the compressor. They irritate the nasal passages and can be detected in very small concentrations. They can be removed by an appropriate grade of activated carbon or by molecular sieves.

Odours

These can be a problem, even when the compressor is correctly sized, sited and well maintained. The presence of odour is to some extent subjective and is therefore unreliable when used as the only means of monitoring for saturated elements. The most effective and common approach to odour removal is the use of activated carbon as the absorbent. These elements, as mentioned above, have a limited life, particularly when the compressed air has a significant moisture content and need replacement at intervals depending upon the concentration of vapours which they have to absorb. Compressed air which may contain trace gaseous elements such as oxides of carbon and nitrogen, methane, ethylene, ammonia, sulphur compounds, etc, cannot be effectively purified by activated carbon alone. Chemical, catalytic or selective adsorption means can also be used to eliminate these impurities.

Packaged systems

Several complete packaged purification systems are available which take untreated compressed air and purify it to the highest standards. They are available for high and low pressure use and range from the replacement cartridge type to the automatic self regenerating type for continuous use.

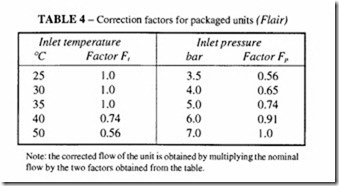

Whatever system is used, it is fundamental to the safety of the user that the specified system shall be capable of providing quality air of a consistently high standard under varying environment conditions. Product integrity, quality assurance and verification are essential characteristics of any supplier of breathing air equipment. A system should be calculated on the basis of 180 litre/min (II m3/hr), based on an inlet pressure of7 bar and 20°C. For other pressures and temperatures, the purifier should be derated in accordance with Table 4. Units are available to serve up to 24 masks.

Note: the corrected flow of the unit is obtained by multiplying the nominal flow by the two factors obtained from the table.