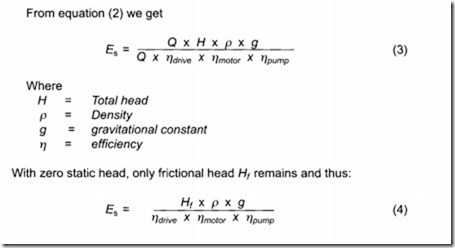

Systems without static head or closed loop systems

The specific energy here is dependent on the frictional head loss which, in turn, is determined by the losses in the pipe system (including throttling valves), and by the combined drive-motor-pump efficiency.

The combined drive-motor-pump efficiency has to be evaluated for each duty point. It is to be noted that the pump efficiency remains approxi mately the same in a system of this type when the speed is changed, whereas the drive-motor efficiency can drop drastically as the load is reduced. If on the other hand, the system curve is changed by changing the setting of a valve, this will change the duty point of the pump and, hence, its efficiency.

Related posts:

Energy and Efficiency:Output energy available

System selection considerations:System economics and Material considerations

ACTUATORS:Piston- Type Cylinders

BASIC DIAGRAMS AND SYSTEMS:FLUID POWER SYSTEMS

Health and safety:Explosion protection

First approximation design methods:Operating point and Solids loading ratios.

Design procedures:Logic diagram for system design

Applications of hydraulic systems:Advantages of hydraulic systems

Hydraulic pumps:Pump performance

Hydraulic pumps:Pump selection

The flapper-nozzle.

Fundamental Principles:Pressure measurement

Safety, Fault-Finding and Maintenance:safety

THE SECOND LA W OF THERMODYNAMICS:HEAT ENGINES

THE SECOND LA W OF THERMODYNAMICS:THE CARNOT REFRIGERATOR AND HEAT PUMP