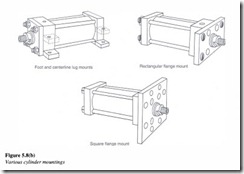

Cylinder mountings

There are various types of cylinder mountings in existence. This permits versatility in the anchoring of cylinders. The rod ends are usually threaded so that they can be attached directly to the load, a clevis, a yoke or some other mating device.

Through the availability and use of various mechanical linkages, applications involving hydraulic cylinders are limited only by the ingenuity of the fluid power designer. These linkages can transform a linear motion into either an oscillating motion or a rotary motion. In addition, linkages can be employed to increase or decrease the effective leverage and stroke of a cylinder.

Listed below (Figure 5.8(a)) are schematics of typical hydraulic cylinder linkages used in a majority of modern day applications.

In order to facilitate the smooth working of these mechanical linkages, various cylinder mountings have been developed, as shown in Figure 5.8(b).

The problem of side loading in hydraulic cylinders due to misalignment has been one of the most discussed topics since they have a significant bearing in evaluating cylinder life and performance. Various efforts have been undertaken from time to time by cylinder manufacturers, to minimize or eliminate this problem altogether. A fact that is increasingly being acknowledged is that it is almost next to impossible to achieve perfect alignment in cylinders.

The advantages of these types of mounting accessories are:

• Ease of mounting

• Reduced cylinder binding and side loading

• Allowance for universal swivel

• Reduced bearing and tube wear

• Elimination of piston blow-by, caused by misalignment.

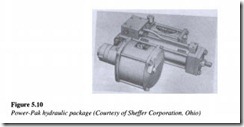

In Figure 5.10, we see a unique, compact, self-contained hydraulic package called the Power-Pak by its manufacturer.

It supplies force in situations warranting minimum size and maximum power. In order to provide flexibility in operation, the selection of speed and power is provided. This arrangement consists of a heavy-duty hydraulic cylinder, a reversible electric motor, a reversible generator pump, a reservoir and automatic valving. This package is a complete hydraulic power system, simple in design and easy to be put into operation.