Servo valves

Introduction

The hydraulic systems, subsystems and hydraulic components that have been discussed so far have had open-loop control or in other words power transfer without feedback. We shall now take a look at servo or closed loop control coupled with feedback sensing devices, which provide for a very accurate control of position, velocity and acceleration of an actuator.

A servo valve is a direction control valve, which has an infinitely variable positioning capability. Thus, it controls not only the direction of the fluid flow but also the quantity. In a servo valve, the output controlled parameter is measured with a transducer and fed back to a mixer where the feedback is compared with the command. The difference is expressed in the form of an error signal which is in tum used to induce a change in the system output, until the error is reduced to zero or near zero. A typical example is the use of a thermostat in an automatic furnace whose function is to measure the room temperature and accordingly increase or decrease the heat in order to keep it constant. Let us now discuss in brief, the various components that comprise a servo system.

Servo components

Supply pumps

Servo systems generally require a constant pressure supply. Since fixed displacement pumps give out excess heat resulting in power loss, pressure-compensated pumps are commonly employed as they are ideally suited for servo operations.

Servo motors

Piston motors are generally preferred over gear or vane-type motors because of their decreased levels of internal leakage. Both in-line and bent-axis type piston motors are used in servo operations although the in-line type has more frictional drag. This is not a serious limitation because in usual circumstances, this drag does not normally exceed the normal damping required for good servo stability.

Servo cylinders

Two important considerations in the selection of a servo cylinder is the leakage flow and the breakaway pressure which is in fact a measure of the pressure required to generate the necessary breakaway force. The rod is usually sealed with V-type and 0-ring type seals since they provide reasonable resistance to external leakage.

Servo transducers

The function of a transducer is to convert a source of energy from one form to the other (for example from mechanical to electrical). In a servo system a feedback transducer after measuring the control system output generates a signal that is in tum fed back into the system for comparison with the input.

Transducers are also used in servo operations for instrumentation purposes, in order to measure the various parameters. Some of the important considerations in the selection of a transducer are the accuracy levels required, resolutional ability and repeatability. Transducers are generally categorized into digital and analog types. They may also be classified on the basis of their function as:

• Velocity transducers

• Pressure transducers

• Positional transducers

• Flow transducers and

• Acceleration transducers.

There are two basic types of servo valves that are widely used. They are:

1. Mechanical-type servo valve

2. Electro hydraulic servo valve.

Mechanical-type servo valve

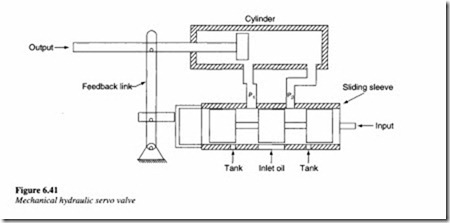

Figure 6.41 shows a typical mechanical servo valve construction.

This valve is essentially a mechanical force amplifier used for positioning control. In this design, a small impact force shifts the spool by a specified amount. The fluid flows through port P o retracting the hydraulic cylinder to the right. The action of the feedback link shifts the sliding sleeve to the right until it blocks off the flow to the hydraulic cylinder. Thus, a given input motion produces a specific and controlled amount of output motion. Such a system where the output is fed back to modify the input, is called a closed loop system.

One of the most common applications of this type of mechanical hydraulic servo valve is in the hydraulic power steering system of automobiles and other transport vehicles.

Electro-hydraulic servo valve

In recent years, the electro-hydraulic servo valve has well and truly arrived on the industrial scene. The main characteristic of an electro-hydraulic valve is that its hydraulic output flow amplitude is directly proportional to the amplitude of its electrical DC input current. Typical electro-hydraulic valves use an electrical torque motor, a double nozzle pilot stage and a sliding spool second stage.

The torque motor includes components such as coils, pole pieces, magnets and an armature. The armature is supported for limited movement by a flexure tube. The flexure tube also provides a fluid seal between the hydraulic and electromagnetic portions of the valve. The flapper attaches to the center of the armature and extends down, inside the flexure tube. A nozzle is located at each side of the flapper such that the flapper motion varies the nozzle opening. Pressurized hydraulic fluid is supplied to each nozzle through an inlet orifice located at the end of the spool. A 40-rnicron screen that is wrapped around the shank of the spool, filters this pilot stage flow. The differential pressure between the ends of the spool is varied by the flapper motion between the nozzles.

The four-way valve spool directs flow from the supply to either control port C, or C2 in an amount proportional to the spool displacement. The spool contains flow-metering slots in the control lands that are uncovered by the spool motion. Spool movement deflects a feedback wire that applies a torque to the armature/flapper. Electric current in the torque motor coil causes either clockwise or anti-clockwise torque on the armature. This torque displaces the flapper between the two nozzles. The differential nozzle flow moves the spool to either the right or left. The spool continues to move until the feedback torque counteracts the electromagnetic torque. At this point, the armature/flapper is returned to the center, the spool stops and remains displaced until the electrical input changes to a new level, thus making the valve spool position proportional to the electrical signal.

A simple description of the overall operation of an electro-hydraulic system can be made by referring to the following block diagram (Figure 6.42).

The electro-hydraulic servo valve operates from an electrical signal to its torque motor, which positions the spool of a direction control valve. The signal to the torque motor comes from an electrical device such as a potentiometer. The signal from the potentiometer is electrically amplified to drive the torque motor of the servo valve. The hydraulic flow of the servo valve powers an actuator, which in tum drives the load. The velocity or position of the load is fed back in the form of an electrical input to the servo valve via a feedback device such as tachometer generator or potentiometer. Since the loop gets closed with this action, it is termed a closed loop system.

These servo valves are effectively used in a variety of mobile vehicles and industrial control applications such as earth moving vehicles, articulated arm devices, cargo handling cranes, lift trucks, logging equipments, farm machinery, steel mill controls, etc.