VIDEORECORDER DECK CONTROL

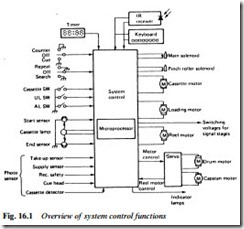

Modern videorecorders require a comprehensive deck control system to act as a ‘clearing house’ for user instructions and feedback information from deck status sensors, and to ensure correct sequencing of deck functions. It must protect the tape and deck mechanism from damage, prevent the user invoking conflicting or damaging commands, and present (in most machines) a front panel or on-screen display of the function in progress, the presence of the tape cassette and a warning of any malfunction or danger situation. An overall block diagram of the syscon (systems control) section of a videorecorder is given in Fig. 16.1. As can be seen there is a multiplicity of inputs and outputs, now to be dealt with in turn.

SYSCON INPUTS

The primary input lines to system control come from the user’s keyboard, be it on the front panel or on a remote handset. The main key functions, and the resulting actions of the syscon are as follows:

1. Play: Check cassette LED operation and end sensor signals.

Unbrake reels, start capstan and head motors, initiate thread- ing procedure; stop threading motor at threading end, unblank video and audio replay channels when servos locked; monitor deck functions thereafter

2. Record: As above, but first check for presence of cassette record- safety tab; switch on erase oscillator, switch sound and vision signal circuits to record; route head flip-flop squarewave to control-track head; switch servos to record mode; lock channel selector

3. Pause: Stop tape motion by braking capstan motor or withdrawing pinch roller; override deck rotation-sensor outputs to prevent stop mode being entered; start pause-time clock to prevent tape damage by entering ‘stop’ after a 5 minute period. In play- pause: shunt tape to correct point for noise-bar elimination and invoke artificial field sync pulse generator; in record-pause (some models) rewind tape 20–25 frames and prime edit-start circuit (see later)

4. Cue: Speed forward motion of tape via capstan or reel drive motor; speed up head drum to maintain correct fh; switch to ‘trick’ video heads where applicable; disable vision and sound blanking circuits

5. Review: Reverse and increase speed of capstan and/or reel drive motors; slow down head drum to maintain correct fh; switch to ‘trick’ video heads where applicable; disable blanking circuits; switch servos as necessary

6. Fast forward: Stop, unthread tape (some models), unbrake reels, turn take-up reel to fast clockwise, monitor end-sensor and any auto-cue system based on control-track markers i.e. QPF, APS; monitor counter-memory sensor and enter ‘stop’ when counter memory reaches 0000 or end-sensor fired

7. Fast rewind: As above, but turn supply reel anticlockwise and monitor tape start-sensor

8. Stop: Withdraw pinch roller, unthread, switch off capstan and head motors, brake reels, release lock on cassette cradle, switch vision and sound circuits to E-E mode

9. Eject: Check for and if necessary initiate stop mode; switch on cassette transport motor; extinguish ‘tape-in’ indicator

10. Audio dub: As ‘play’ but switch sound circuits to record and inhibit passage of bias oscillator signal to full-erase head In addition to these command inputs, various feedback and guard sensors on the deck form a second important group of syscon inputs. These are:

1. Cassette-in detector: An optical or mechanical sensor activated by the plastic cassette shell. With no cassette present all deck functions are inhibited

2. Record tab sensor: A ‘feeler’ to detect the presence or absence of the removable erase-prevention tab on the cassette shell. With no tab, record mode is inhibited

3. Drum rotation sensor: Head PG or flip-flop waveform is monitored to assure continued rotation of the head; its absence will invoke stop mode

4. Spool rotation sensors: As above, but derived from Hall-effect magnet or optocoupler on spool turntable. To prevent tape dam- age, syscon enters stop when alternating sensor signal ceases

5. Tape start- and end-sensors: At each front corner of the cassette is mounted a sensor which detects the presence of the leader tape at the extreme ends of the ribbon; a lamp shining through the clear leader tape is used. When tape start is detected, any rewinding function is disabled; at tape end, only rewind commands will be accepted. Many machines have an auto-rewind feature, in which stop then rewind modes are consecutively entered by the syscon on receipt of ‘tape-end’ signal

6. Slack sensor: If at any point the tape becomes slack, the machine has malfunctioned and the tape could get damaged. Tape slack is detected by cessation of take-up reel rotation pulses

7. Dew detector: A resistive humidity detector fitted to the head- drum assembly inhibits all deck functions via the syscon if moisture has gathered. This prevents tape, drum and motor damage from the ribbon sticking to the drum surface. Very often a dew warning is provided on the front panel of the machine, and in some designs a head-heating element is switched on to dry the drum

8. Loading start/end sensors: All videocassette recorders have electrically driven tape loading/threading mechanisms. Until load-end is reached the loading motor must remain on, and many other mechanical functions inhibited; similarly, the tape must be fully unthreaded before head, capstan and loading motors can be switched off and the cassette released from the machine

9. Loading motor lock: If the loading motor stalls during load or unload the machine switches off altogether; this is particularly relevant to battery-operated portable videorecorders and cam- corders.

In most videorecorders and in portable types, some of these deck status signals are given by a mode switch, a multi-contact slider or rotary type mechanically linked to the mechanics of the reel drive and tape-loading mechanism.

A further set of commands come to the syscon from areas other than the keyboard and deck sensors, as follows:

1. Timer command: At times preset and programmed by the user the deck is given ‘record’ and ‘stop’ signals from the timer section, which itself will select the programme-channel chosen by the absentee user. Some types of videorecorder use a single microprocessor, custom-designed and internally programmed for syscon, timer clock and display-drive functions

2. Power interrupt: If a power failure occurs during record or playback all motion ceases instantly; on restoration of power the machine will unload and stop. Some designs permit resump- tion of timed (pre-programmed) recording after a power cut. If the power switch is turned off during any ‘moving’ function the machine will unload and enter stop before turning off

3. Low battery: In portable equipment the battery voltage is monitored and at about 88% of normal voltage the unit enters stop and turns off completely to prevent over-discharge dam- age. The approach of this situation is often warned of by a flash- ing light on the control panel or in the viewfinder

4. Counter memory: a stop command passes into the syscon when the tape counter passes 0000 with the memory button depressed. In more sophisticated designs a ‘counter go-to’ number can be programmed into the keyboard, whereupon the syscon will drive the tape in either direction to the required count point

5. Remote control: A full remote control system duplicates the control panel functions, and will be dealt with below and in Chapter 22. Particularly relevant to portable equipment is the camera trigger which operates the record-pause function described early in this chapter.