Vacuum techniques

Vacuum technology includes all systems utilizing a pressure less than atmospheric, taken as 1.013 bar. Vacuum is usually measured in the unit torr (after Torricelli who invented the barometer) which is equal to a pressure of Imm of mercury. Torr is not anSI unit, so for consistency in calculations it is preferable to quote vacuum in pascal (Pa), kilopascal (kPa) or bar. The conversion factors are:

The reason for preferring torr is that vacuum is most often measured by a barometer or a manometer which gives a direct reading of vacuum as a measurement of a liquid column.

The complete vacuum range can be divided into 5 classes:

• Low vacuum- pressures down to 25 torr.

• Medium vacuum -25 torr down to J0·3 torr.

• High vacuum- I0-3 down to I0-6 torr.

• Very high vacuum- I0-6 down to I0-10•

The most common use of vacuum in industrial processes is to reduce the boiling point of water contained in a product in order to accomplish one of the following:

• to prevent thermal damage to the product when heat is applied to vaporise and effect mass transfer to the water and hence dry the product.

• to speed up the process.

• to ensure very low residual moisture content difficult to dry by other means. examples are distillation, evaporation, vacuum drying of liquids and solids and freeze drying-processes.

Vacuum cooling is closely allied to vacuum drying and is a simple mass transfer process which results in cooling of the product by the removal of a controlled quantity of moisture.

Depression ofthe vaporisation point is also the objective of vacuum coating processes in which metals and other materials are melted, evaporated and eventually sublimated on a prepared substrate. The high vacuum condition prevents oxidation of the material evaporated at high temperature.

Simple removal of atmospheric air and moisture so that they can be replaced by another gas or liquid is the reason for the use of vacuum in impregnation; in filling of capillaries and containers with small orifices; in some vacuum investment and die casting processes and in refrigeration, cryogenic and gas filled cooling system evacuation; electric lamp and switch gear evacuation and inert gas welding.

In packaging of food, vacuum is applied to remove atmospheric air from the pack so that

the contained product will have an increased shelflife, once it is sealed with an impervious pack. An important aspect of vacuum packaging for some products is the differential pressure between interior and exterior which causes the flexible pack material to collapse and cling to the product, providing increased structural strength.

Vacuum coating

This technique is used for applying a thin (0.1 J.l.m) aluminium coating on metals and plastics, which appears as a reflective film. The aluminium is evaporated by tungsten filaments at a vacuum of0.2 X 10·3•

Ion plating is a further development which allows the deposition of various metals, titanium and carbides. Rather thicker coatings arepossible. The air in the vacuum chamber is replaced by argon gas. A high potential produces a gas stream and evaporates a metal source which is then deposited on the surface of the component.

Mechanical processes

There are numerous ways in which low vacuum can be used for mechanical handling and low cost automation. Some examples are:

• High speed paper feeding for printing and processing.

• Vacuum forming of thermoplastics.

• Liquid filling.

• Dry powder filling.

• Continuous liquid/solid separation.

• Air sampling.

• Vacuum feeding of metal timber and glass sheets.

• Machine tool chucks and vices.

• For gripping components during automation.

Applications of low or coarse vacuum

Some typical applications using low vacuum are illustrated in Figure 1.It will be noted that in each application, a filter, vacuum gauge and relief valve are required in the circuit. In addition, according to the application, a liquid trap and a vacuum release valve may be required. When using a suction cup for material handling, a vacuum check valve is fitted for security in the event of pump failure; this ensures that vacuum is retained in the cup.

Laminating Press Vacuum is used to eliminate bubbles in laminating and ve neering hard board. plastics. and wood .

Mobile Material Handling with Vacuum Vacuum equipped tift trucks eliminate fork or clamp damage.

Rolls can be rotated to either stack or load in machinery.

Blood Taking Equipment Plastic blood collection bag inserted in rigid flask. Vacuum applied to flask draws blood from patient into plastic bag.

vacuum Egg Lifters Feather-light egg handling w ith vacuum uses a special accordion pleated suction cup which lifts and holds each egg.

Centrifugal Pump Priming Vacuum priming of centrifugal pumps assures quick start pump ing. Prevents pump burnout from running dry.

Vacuum Column to Hold Slack in Computer Tape High speed computer tape requtres slack to protect tape from snappmg apart dunng fast starts and stops. Slack 1n tape JS held and controlled by vacuum

Suction cups and pads

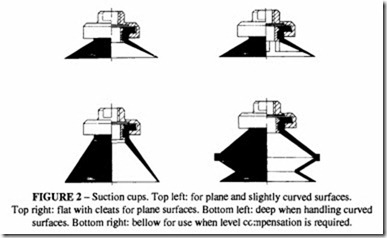

A variety of designs of suction cups are available, for use: according to the shape of the surface to which they are to be attached. Figure 2 shows some typical shapes.

In calculating the holding force of a cup it is customary to take the maximum force as the product of the area of the inner sealing lip and a pressure corresponding to 75% vacuum. In addition it is recommended that minimum safety factors of 2 for horizontal surfaces and 4 for vertical surfaces should be used.

When using vacuum pads, the response time (the time taken for the vacuum to reach the design level) should be calculated. When using suction for component handling, it is important the next stage of the operation should not start until the correct depression is reached. The total internal volume of the pipework and fittings up to the pad should first be calculated and the formulas in the next chapter used to determine the response time.

Cups are made of oil resistant rubber or, if a wide range of temperatures is required, of silicone rubber. Nitrile, urethane and fluoro-rubbers may be used. They are commercially available in diameters from 6 mm to 300 mm.lt is usually preferable to use several small cups rather than one large one.

Figure 3 shows some typical circuits using ejectors with suction cups; note the various attachment methods. These venturi ejectors are frequently used in this application. Although they consume mains air and overall are not as efficient as vacuum pumps, their simplicity and reliability makes them the favoured method for many automation applica tions. See Figure 4.

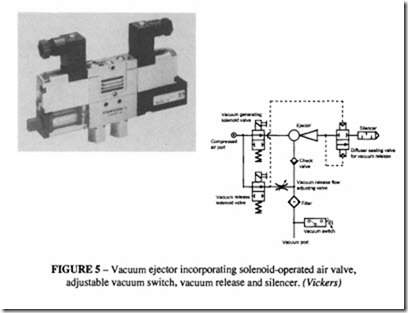

Combined ejectors and solenoid- (or pilot-operated) valves are available for building into an application, Figure 5.

Itmay be necessary, in some applications, to apply a positive pressure to release the cup.