Pipelines and valves

Introduction

Decisions with regard to the specification of components for pneumatic conveying systems do not end with the feeder, air mover and filtration system. There are likely to be numerous valves on the plant, and the pipeline is just as important. This importance is significantly magnified if the material to be conveyed is abrasive.

Pipelines

Decisions do have to be made with regard to the pipeline. Material, wall thickness, surface finish, steps and bends to be used, all have to be given due consideration. One of the most critical parameters with regard to the successful operation of a pneumatic conveying system is maintaining a minimum value of conveying air velocity for the material to be handled. For the dilute phase conveying of granulated sugar, for example, this is about 16 m/s. If the velocity drops to 15 m/s the pipeline is likely to block.

Wall thickness

The volumetric flow rate of the air required is obtained by multiplying the conveying air velocity by the cross-sectional area of the pipeline, and making due note of both the pressure and temperature of the air. The diameter of a 4 in. nominal bore pipeline, however, is rarely 4 in. If a conveying air velocity is based on a diameter of 4 in., for example, and it is a schedule 10 pipeline, the actual bore will be 4.026 in. (106.1 mm) and not 4.000 in. (101.6 mm). This difference will mean that the conveying air velocity will be about 9 per cent lower. If 16 m/s is the velocity in a 101.6 mm bore pipeline, it will only be 14.6 m/s in a 106.1 mm bore line, and the pipeline is likely to block.

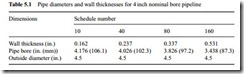

If an abrasive material is to be conveyed, wear of the pipeline must be expected. To give the pipeline a longer life, pipe having a greater wall thickness should be used. Schedule numbers are often used to specify wall thickness. Typical dimensions for 4 in. nominal bore pipeline are given in Table 5.1.

If the material to be conveyed is not abrasive at all, a thin walled pipeline should be suitable for the duty. Pipeline weight in kg/m could be added to Table 5.1 and this would show a marked difference. Lighter pipe sections will certainly make construc- tion of the pipeline easier, particularly if there are vertical sections to erect.

Pipeline rotation

If a pipeline is to convey materials having a very large particle size, the particles will tend to ‘skip’ along lengths of horizontal pipeline. This is as a consequence of the greater influence of the gravitational force over the drag force on the particles. If the material being conveyed is abrasive, then a groove is likely to be worn along the bot- tom of the pipeline. Mild steel pipeline is particularly vulnerable to this type of wear. This is because erosive wear of ductile surface materials is very high at low, glancing, angles of impact. The subject of erosive wear is considered in detail in Chapter 23.

If this type of material does have to be conveyed, then a thick walled pipeline would be recommended, but if the pipeline was to be rotated periodically, this would also extend the life of the pipeline very considerably. For this purpose the pipeline should be located in a place where convenient access can be gained for the necessary changes to be made.