Conveying systems

A wide range of pneumatic conveying systems are available to cater for an equally wide range of conveying applications. The majority of systems are generally conventional, continuously operating, open systems in a fixed location. To suit the material being conveyed or the process, however, innovatory, batch operating and closed systems are

commonly used, as well as mobile systems. To add to the complexity of selection, systems can be either positive or negative pressure in operation, or a combination of the two.

Closed systems

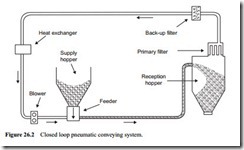

For the conveying of toxic or radioactive materials, where the air coming into contact with the material must not be released into the atmosphere, or must be very closely regulated, a closed system would be essential. A sketch of a typical system was given in Figure 2.10 and is reproduced here as Figure 26.2 for reference. A closed system may also be chosen to convey a potentially explosive material, typically with an inert gas. In a closed system the gas can be re-circulated and so the operating costs, in terms of inert gas, are significantly reduced.

A null point needs to be established in the gas only part of the system, where the pressure is effectively atmospheric, and provision for make up or control of the conveying gas can be established here. If this null point is positioned after the blower the conveying system can operate entirely under vacuum. If the null point is located before the blower it will operate as a positive pressure system.

Open systems

Where strict environmental control is not necessary an open system is generally preferred, since the capital cost of the plant will be less, the operational complexity will be reduced, and a much wider range of systems will be available. Most pneumatic conveying pipeline and channel systems can ensure totally enclosed material conveying, and so with suitable gas–solid separation and venting, the vast majority of materials can be handled quite safely in an open system. Many potentially combustible materials are conveyed in open systems by incorporating necessary safety features.

Positive pressure systems

Although positive pressure conveying systems discharging to a reception point at atmospheric pressure are probably the most common of all pneumatic conveying systems, the feeding of a material into a pipeline in which there is air at a high pressure does present a number of problems. A wide range of feeding devices is available that can be used, as considered in Chapters 3 and 4. With each type of feeder, however, there is the potential of air leaking from the system, and carrying dust with it, as a result of the adverse pressure gradient.

With the use of diverter valves, multiple delivery to a number of reception points can be arranged very easily with positive pressure systems. Although multiple point feeding into a common line can also be arranged, care must be taken with regard to the potential for air leaking across a number of feeding points when not in use, as a result of the high pressure air in the pipeline.

Negative pressure (vacuum) systems

Negative pressure systems are commonly used for drawing materials from multiple sources to a single point. There is no adverse pressure difference across the feeding device in a negative pressure system and so multiple point feeding into a common line presents few problems. In comparison with a positive pressure system, however, the filtration plant has to be much larger, as a higher volume of air has to be filtered under vacuum conditions.

A particular advantage of negative pressure systems, whether open or closed, in terms of potentially hazardous materials, is that should a pipeline coupling be inadvertently left un-tightened, or a bend in the pipeline fail, air will be drawn into a sys- tem maintained under vacuum. With a positive pressure system a considerable amount of dust could be released into the atmosphere before the plant could be shut down safely. The author has personal experience here, for while conveying cement at 50 tonne/h a flexible hose connecting the blow tank with the pipeline came adrift when the pressure in the line was three bar gauge. It can happen. If it had been a food product, chemical or metal powder, that was being conveyed, the consequences could have been very serious.

Vacuum systems are also widely used for clearing dust released into the atmosphere from many other bulk solids handling operations. This is generally achieved by the use of ventilated hoods. This may be at a material transfer point in a mechanical conveying system, or at a gravity loading station for sack filling from storage hoppers. Mobile conveying systems such as road and rail vehicles require similar ventilation systems when being loaded with bulk particulate materials.