Pipe materials and fittings

Steel is the most common material for main line pipes; ABS copolymer is also used. Copper, stainless steel and various kinds of rubber hose and plastic tubing are suitable for small mains, for branch lines and for connections to tools.

Steel pipes

Steel pipes to BS 1387 are normally specified in the nominal bore sizes given in Table I. Finishes can be black or galvanised, the latter being preferred for corrosion resistance.

Steel pipes are normally used with threaded connections. Above 65 mm nominal bore, welded fittings to BS 1965 are recommended, although cast iron pipes with integral flanges or steel pipes with welded-on flanges may be used. In sizes smaller than 65 mm malleable iron fittings conforming to BS 143 and BS 1256 may be used for pressures up to 10 bar.

Screwed connections, to BS 21, are restricted to metallic tubes with thick walls.

ABS copolymer pipes

The only plastic material recommended as suitable for air mains is ABS copolymer (Acrylonitrile-Butadiene-Styrene). Provided it is used within its limitations it is a very convenient alternative to steel.

The advantages are:

• Corrosion resistant inside and out. No scale or rust can form, so the loss through friction remains low and constant.

• Easy to handle. One-eighth of the weight of steel.

• Easy to joint by cold solvent welding. A correctly made joint cannot leak.

• Self-coloured (light blue) for identification. Meets BS 1710 for compressed air services.

• Non-toxic.

• ABS is available in two pressure ratings NP I0 (up to I0 bar) and NP I2.5 (up to 12.5 bar). The NP I2.5 rating is recommended for airline use.

One limitation on its use is that it softens and loses its strength at increased temperature. It retains its 12.5 bar rating up to 20°C; it should not be used, without reference to the manufacturers, above 50°C, at which temperature its pressure rating is reduced to 8 bar. Installations using ABS must be provided with an aftercooler with a temperature cut-out to ensure that there is no chance of hot air reaching the plastic. Transient pressures up to I 0% over the maximum can be tolerated. In installations where there is some carry-over of oil from the compressor, the manufacturers of the tubing should be consulted, as there may be incompatibility between the tube and the oil; synthetic oils should not be used.

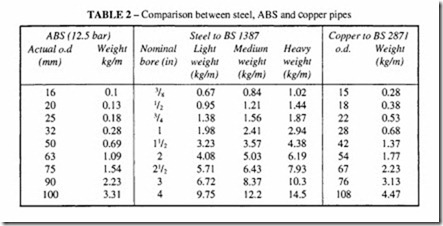

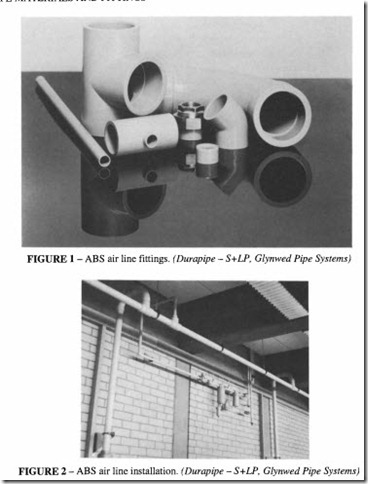

Table 2 compares the weight of ABS with alternative steel and copper pipes. Figure I shows a selection of fittings used with ABS piping and Figure 2 part of a mains system. Note that screwed fittings may not be used for direct connection to the pipe; only solvent welding is permissible.

ABS pipe may be used underground or in overhead installations.

Copper pipe

Copper tubing for air lines should conform to BS 287 I :Part I. No other earlier standards should be used. It is almost invariably used with compression fittings to BS 2051: Part 2.

Copper piping is not normally used for air mains, but because of its ease with which it can be manipulated and joined it is common for branch lines. The cost is higher than steam barrel or ABS. Care should be taken when forming bends; any of the usual bending techniques are permissible, but a smooth ripple-free inner surface is essential to minimise pipe friction.

Steel thin-wall pipes

Thin-wall tubes made of stainless steel or carbon steel are also occasionally used. Compression fittings in stainless steel or brass are used for joining.

Bundy tube

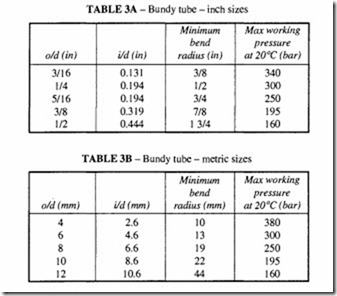

Bundy tube is constructed from copper coated steel strip, rolled twice laterally and furnace brazed to produce a double wall tube with a copper bore and a tinned external surface. It has a higher working pressure than copper tube (Table 3) and can be joined with standard compression fittings.

Aluminium tube

This is a recent development, using extruded section anodised aluminium (Figure 3). The advantage of this material is that its smooth interior results in a low friction factor and

consequently a low pressure loss compared with steel pipes (it is quoted as carrying up to 50% more air than steel); see Table 7. Its light weight at about one-third that of steel makes it easier to support. It is non-corrodible by the normal contaminants of an air system. An installation using this material has to have special connections which can be readily attached to the flat side of the extruded section. Because it is only supplied in straight lengths, changes in direction are sharp, which means that the pressure loss at a right angle bend is greater than for a steel swept bend.

Nylon tubes

Nylon tubing is commonly used to connect small hand tools to a branch line and for making up circuits in automation applications. It is available in flexible or semi-rigid forms; and manufactured from nylon II or nylon 12 to BS 5409. It can be used for working temperatures up to 80°C, or for short periods up to 120°C (after reference to the manufacturers). It can be obtained in a variety of colours as well as transparent. For use

To calculate the working pressure at the given temperature. multiply working pressure at 20°C by the factor in the table.

outside or where it is exposed to daylight over a long period, black tube should be specified as this is ultra-violet stabilised.

Tables 4 and 5 give strength and size information for sizes up to 28 mm old, however for pneumatic circuits 12 mm is the usual maximum. Although only metric sizes are quoted here, inch sizes are usually also supplied as an alternative.

Two forms of pipe fittings can be used with nylon tubes: compression fittings as for copper pipes and push-in tube fittings. The latter are available for nylon tubes up to 12mm old (some manufacturers also supply 14 mm). Connections to push-in type fittings are easily made and dismantled so they are very suitable for making up complex circuits which may require to be made and unmade several times. The maximum pressure rating of these fittings is 10 bar.

Nylon spring coils

Spring coils of nylon are also available. Their use obviates the need for trailing hoses or in any application involving a large relative movement between components. See Figure 4 and Table 6.

Nylon springs coils are manufactured from a special hard nylon with good mechanical strength and chemical resistance properties. ensuring suitability for a wide range of applications. Each spring coil is supplied with a leader at each end and will extend up to a maximum of 5 m (wound anti-clockwise).

Terylene braided PVC hoses

Unreinforced PVC hose is not recommended for use with compressed air but when reinforced with terylene it makes a satisfactory alternative to nylon. End connections are usually swaged or made with 0-clips. The working pressure is approximately the same as for nylon tube.

Rubber hose

This is probably the most common material for connecting tools and mobile equipment to a compressor or to a main airline. Rubber hose for airline use should meet the requirements ofBS 5118, Types 1 to 3. The construction has a two-ply textile reinforce ment in which cords of high tensile textile yarn, fully embedded in rubber, are laid spirally along the hose giving maximum strengthandflexibility. For high pressure use, high tensile steel is used in place of the textile. Rubber hose with an outer thermoplastic cover is also available with an added resistance to abrasion and improved weathering properties. Rubber hose has a temperature capability from -30°C to 70°C.

Hose couplings

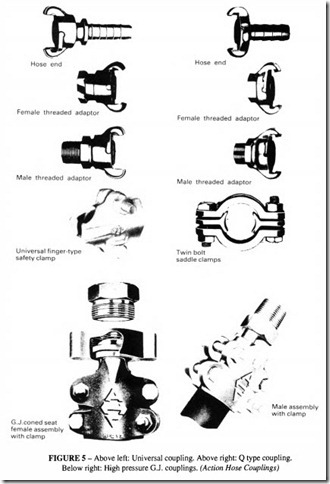

A variety of different hose couplings are available. For low to medium pressure applications quick action claw couplings are commonly used, Figure 5. Two types of these are found: the ‘Universal’, American Style with NPT threads as standard and the ‘Q Type’ European Style with BSP threads as standard.

The Universal Style is also known as ‘Air King’, ‘Chicago Type’, ‘Lindy’ and ‘Crowsfoot’. It is interchangeable with the Chicago Pneumatic Type but not the European Type. The seal is by a captive rubber ring in the coupling. Finger-type safety clamps are recommended; these have an extended finger which locks over the security collar of the coupling. With the safety lock pin, the working pressure is 12 bar.

The Q Type meets German standards DIN 3482 and 3483. Twin bolt saddle clamps are recommended; these must match the hose outer diameter. Sealing is by a rubber ring. The working pressure is 7 bar. A safer variation of this is the ‘Safeloc’, incorporating a security collar and lug extensions, facilitating the use of a safety lock pin; this too has working pressure of 12 bar.

For high pressure use, ground joint (GJ) safety clamps are used. These are threaded connections of a knock-on design. The hose stem has a coned end which seats on the coned face of the spud; the spud has a copper insert giving soft-to-hard metal seating. Finger type clamps are recommended: the smaller size (up to 19mm) have two bolts; larger sizes have four bolts. Working pressures vary from 260 bar in the 12mm size to 70 bar in the 50 mm size.

Swaged and reusable hydraulic type hose couplings are also used, particularly for high pressure use.

Compression fittings

These fittings are usually manufactured from brass bar to BS 2874 and brass stamped components to BS 2872, Figure 6. The dimensions should be in accordance with BS 2051:Part 1 and may be used with copper, aluminium alloy, bundy and nylon tubes. Stainless steel fittings are also available.

Compression fittings are of two kinds: if the tube material is deformable, a brass or copper collet is used (as in Figure 6); and where deformation of the tube is unacceptable a captive resilient seal may be used in place of the collet (Figure 7). One advantage of the resilient seal is the ability to make and remake the joint many times. Deformable collets can be used for air pressures up to 200 bar, but resilient seals are limited to 10 bar. In order to prevent collapse of soft plastic tubes tube inserts are available. It will be found that the use of copper collets will tend to narrow the bore of the tube and restrict the flow as will the use of inserts, so where possible, if the working pressure is not too high, the use of resilient seals is recommended. Fittings are available in a wide variety from suppliers of pneumatic equipment.

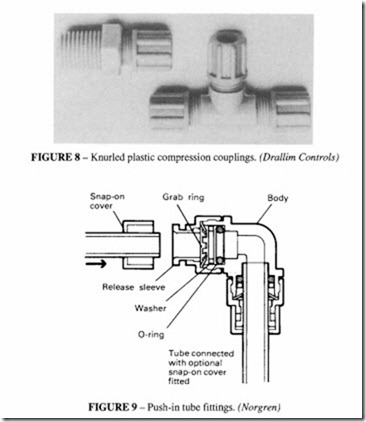

As well as brass compression couplings, a range of polyamide (nylon) fittings with knurled polypropylene union nuts are available in sizes up to 12mm old tube for pressures up to 10 bar and up to 90°C, Figure 8. PTFE (polytetrafluoroethylene) and PVDF (polyvinylidene fluoride) fittings are also made.

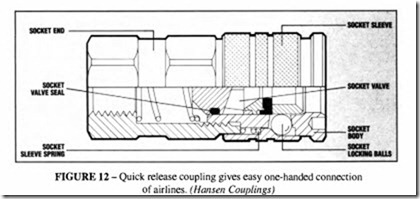

In recent years push-in fittings have become popular for medium pressure (up to 10bar) connections, particularly for use with nylon tubes although some types accept copper. These fittings are very convenient because of their ease of use: no spanners are needed and

connections can be made and remade without the need of special tools other than a means of cutting the tube. One type, illustrated in Figure 9, has an acetal co-polymer body; it seals with an 0-ring and has a steel grab ring to grip the tube; a special release tool is recommended for disengaging the tube from the grab ring. Another type, made up as a manifold, is illustrated in Figure 10; it has a brass body and a sliding collet with gripping teeth for positive anchorage of the tube. The fitting is disconnected by pulling back the collet and withdrawing the tube. This particular fitting contains a shut-off valve which is held closed by a spring, so that only those connections that have a tube inserted can pass air.

Figure 11 shows another type of push-in fitting, detailing the ease of assembly.

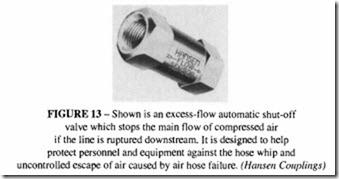

Quick release couplings

These couplings are used for connections which have to be made frequently, eg where a variety of tools are employed at one location and need to be plugged in alternately.

Connections can be made and remade under pressure; the ends should be self sealing so that after disconnection the air cannot leak. Some types incorporate a bleed hole so that the down stream pressure is vented before disconnection; this eliminates one of the causes of whipping hoses. Couplings can be single or double cut-off according to whether one or both ends of the line are needed to be sealed. Most of the quick release couplings have a swivel action which reduces strain on the connection and thereby increases the life of the hose. See Figure 12.

They are made from brass, steel or plastic (usually Delrin). Plastic couplings have a pressure limit of 10bar. Some of the couplings are supplied with a hose stem with a barbed

tooth, which are claimed to make a safe connection merely by pushing into the end of the hose. This is not to be recommended, except for diameters below about 6mm. It is preferred to use a worm hose clip.

If one quick release coupling is to be used it should be fitted at the rigid end or next to the compressor, rather than at the tool. The reason for this is the danger of damage to the coupling by the vibration of the tool or merely by handling.

If a self sealing coupling is not used, a shut off valve should be fitted upstream of the hose connection to allow hoses to be changed.

Excess flow valves

One danger inherent in the use of flexible hoses is “hose-whip” which occurs when there is an unexpected downstream break in the line; the hose lashes about uncontrollably which can only be ended by turning off the compressor or isolating the affected partofthe system. This can be readily cured by fitting an excess flow shut-off valve which safely stops the main flow. This valve should be employed in all situations where hose rupture due to mechanical damage is a possibility. Figure 13 shows such a valve. It works by cutting off most of the flow when the pressure drop at the valve is excessive. The flow that remains is insufficient to cause hose whip.

Working pressure is 14 bar. Extrusion length 5m. Maximum temperature 130°C.