ACTUATORS

PNEUMATIC CYLINDERS

Cylinders are the muscles of pneumatic systems. The valves and other control devices simply provide the correct amount and pressure of air at the required time to the cylin ders. The cylinders then produce linear motion. This linear motion is ideally suited for opening and shutting large valves and moving the large loads that are commonly found in power stations and other industrial complexes.

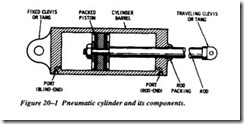

A pneumatic cylinder basically consists of a cylindrical body, a piston rod, a closed end with an outlet port, and the other end with a cylinder head through which the pis ton rod slides in and out. A rod seal in the cylinder head prevents air blow-through when the cylinder is pressurized. Figure 20-1 shows a typical pneumatic cylinder and its components.

Cylinders can be found in many different sizes and can vary in stroke output depend ing upon the designed application. Some are constructed for use in very low-pressure systems and work capacities; others perform incredible load-moving feats utilizing

extremely high pressures. Cylinder designs come in many sizes, and are usually described in the following manner:

2 inches by 10 inches

The “2 inches” describes the diameter of the cylinder and the “10 inches” describes the stroke ofthe cylinder (how far the piston rod moves). Cylinders vary in design, but the following designs are standard

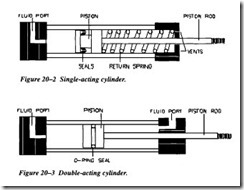

Single-Acting Cylinders

In this cylinder design (Figure 20-2), there is only one pressure port. Instead of switching pressure to the opposite side of the piston head to reverse the cylinder, a spring inside the cylinder (fitted between the backside of the piston head and the cyl inder head enclosure), or the load itself, reverses the cylinder’s movement.

Double-Acting Cylinder

This type of cylinder has two pressure ports (Figure 20-3). Either ofthese ports can be pressurized to cause the piston rod to move in either direction. This design is the most common one in use throughout industry.

Double-End Rod Cylinder

This type of cylinder utilizes two piston rods and two ports. A piston rod extends from both ends of the cylinder and produces a force in both directions.