Preventive maintenance

Most of the production personnel carry the impression that a maintenance department exists primarily to repair the faults that occur. Unfortunately this is not the case. The most important part of the maintenance department’s responsibility is to perform routine planned maintenance otherwise known as preventive maintenance.

Preventive maintenance primarily deals with:

• Regular servicing of the equipment

• Checking for correct operation

• Identification of potential faults and their immediate rectification or correction.

As an often-overlooked side benefit, planned maintenance trains the maintenance technician in the proper operation and layout of the plant for which they are responsible. Most of the common problems listed in the introductory section of this chapter can be eliminated if a planned preventive maintenance program is undertaken.

More than 50% of the problems encountered in hydraulic systems have been observed to be related to hydraulic oil. This is why regular sampling and testing of the hydraulic fluid is a very important. A portable hydraulic fluid test kit is available nowadays. This helps in carrying out the basic tests at the site itself. Tests that can be performed include ones such as determination of viscosity, water content and particulate contamination.

It is vital that the maintenance personnel be trained to carry out maintenance activities effectively. A technician should also be able to recognize the early symptoms of potential hydraulic problems. For example, a noisy pump may be due to cavitation caused by a clogged inlet filter. It might also be due to a loose inlet fitting which permits air ingress into the pump. If the cavitation is due to air leakage in the pump, the oil in the reservoir tends to get covered with foam. When air becomes entrained in the oil, it causes spongy operation of the hydraulic actuators. A sluggish actuator may also be due to the high viscosity of the fluid.

For preventive maintenance techniques to be really effective, it is necessary to have a good reporting and recording system. These reports should include the following:

• The type of symptoms encountered and how they were detected along with the respective date

• A description of the maintenance repairs performed. This should include the replacement of parts, the amount of downtime and the date

• Records of dates when the oil was tested, added or changed

• Records of dates when the filters were cleaned or replaced.

Proper maintenance procedures with respect to external oil leakages are also essential. Safety hazards due to oil spillage on the floor should be prevented. The bolts and brackets of loose mountings should be tightened as soon as they are detected as they can cause misalignment of the pump and actuator shafts.

Sealing devices

Oil leakage in a hydraulic system reduces efficiency and leads to increased power losses. Internal leakage does not cause loss of fluid in the system as the fluid returns to the reservoir. External leakage represents a loss of fluid in the system. An improperly assembled pipe fitting is the most common cause of external leakage. Shaft seals on pumps and cylinders can get damaged due to misalignment, leading to leakages in the system.

Seals are used in hydraulic equipment to prevent excessive internal and external leakages and to keep out contamination. Seals can be of a positive or non-positive type and are generally designed for static or dynamic applications. Positive seals do not allow any leakage whatsoever. Non-positive seals permit a small amount of internal leakage.

Static seals are used between mating parts, which do not move relative to each other. Figure 11.1 shows some of the static seals including flanged gaskets and seals. The static

seals are compressed between two rigidly connected parts . They represent a simple and non-wearing joint, which would be trouble free if properly assembled.

Dynamic seals are assembled between mating parts, which move relative to each other. Dynamic seals are subject to wear and tear as one of the mating parts rubs against the seal. The most widely used seals of this type are:

• 0-rings

• Compression packings

• Piston cup packings

• Piston rings

• Wiper rings .

V-ring packings

V-ing packings are compressible type seals, which are used in virtually all reciprocating motion applications. These include rod and piston cylinders in hydraulic cylinder applications, press rams and jacks. Here, proper adjustment is essential since excessive tightening will accelerate wear and tear.

Piston cup packings

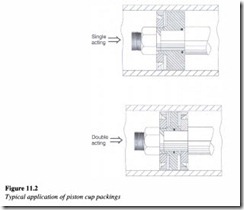

Piston cup packings are designed specifically for pistons in reciprocating pumps and hydraulic cylinders . They offer the best service life for this type of application . Figure 11.2 shows a typical installation of piston cup rings for double acting and single acting operations.

Sealing is accomplished when the pressure pushes the cup lip outwards against the cylinder barrel. The backing plate and the retainers clamp the cup packing tightly in its place, allowing it to handle very high pressures.

Non-metallic piston ring packings

These packings are made out of tetrafluoro ethylene (TFE), a chemically inert, tough waxy solid. Their extremely low coefficient of friction permits them to run completely dry and at the same time prevent scoring of the cylinder walls. This type of piston ring is very ideal for applications where the presence of lubrication can be detrimental or even dangerous.

The following are the most common types of materials used for seals:

• Leather: This is rugged and inexpensive. However it tends to ‘squeal’ when dry and cannot operate above 93 oc (200 °F). Leather also does not operate well at cold temperatures of around -50 °C (-58 °F).

• Buna-N: This material is rugged, inexpensive and wears well. It has a wide operating range between -45 oc (-50 °F) and 121 oc (250 °F) and also maintains good sealing characteristics in this range.

• Silicone: This elastomer has an extremely wide temperature range between -68 °C (-90 °F) and 232 °C (450 °F). Hence it is widely used in rotating shaft seals and static seals. Silicone is not used for reciprocating seal application as it has a low resistance to tear.

• Neoprene: This material has a temperature range of -54 °C (-65 °F) to 120 °C (250 °F). It has a tendency to vulcanize beyond this temperature.

• Viton: This material contains about 65% fluorine. It has become a standard

material for elastomer type seals for use at elevated temperatures up to 260 °C (500 °F). The minimum temperature at which these seals operate is about -29 °C (-20 °F).

• Tetrafluoroethylene: It is a form of plastic and is a very widely used seal material. It is quite tough and chemically inert in nature and has excellent resistance up to temperatures of 370 oc (around 700 °F). It additionally possesses an extremely low coefficient of friction. One major disadvantage with this material is its tendency to flow under pressure forming thin films. This can be neutralized to a large extent by using filler materials such as graphite, asbestos and glass fibers.