Filters

Most problems that occur with filters generally result from incorrect specification, either in terms of the air flow rate or the particle size distribution to be expected.

Material degradation

Filter cloths and screens will rapidly block if they have to cope with unexpectedly high flow rates of fine powder. The net result is that there is usually an increase in pressure

drop across the filter. The sample of material to be conveyed, and hence filtered, that is supplied to a filter manufacturer for selection and sizing purposes, could differ significantly from that which has to be handled by the plant filter installed. The sample pro- vided may be representative of the material to be conveyed, but if it is a friable material, and the conveying air velocity is unnecessarily high, the material at the end of the con- veying line could be very different.

Maintenance

Cloth filters will gradually block with fine material which cannot be shaken free, and their performance will be less effective. Filter bags are an item, therefore, that require periodic replacement. The performance of a filter can be monitored to a certain extent by noting the empty line pressure drop values. If there is a pressure gauge in the air sup- ply or extraction lines the empty line pressure drop can be checked. This pressure drop represents the combined resistance of the pipeline and filtration unit. If the pipeline is purged clear of material, any changes in pressure drop can generally be attributed to the filter. An increase in this pressure drop would indicate that cleaning of the filter is not as effective as it should be and should be checked.

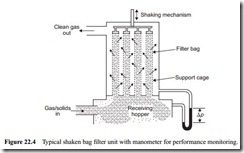

Alternatively an additional pressure gauge could be positioned on the receiving hopper. Most filter units are provided with a pressure tapping for this purpose and so with a pressure tapping on the receiving hopper a differential value for the filter can be obtained. Such a device is illustrated in Figure 22.4 on a mechanically shaken unit. With reverse air jet filters a check should be made to ensure that the air supply for the filter bags and pulsing is correctly connected and of adequate capacity, and that the timer for cleaning is set and operating correctly.

Sizing

The surface area of filter cloth required is based to a large extent on the volumetric flow rate of the air to be handled. The value of the air flow rate, at the local pressure and temperature conditions, divided by the cloth area gives an approximate face velocity. Typical values for felted fabrics are in the region of about 0.025 m/s for fine particulate materials and up to about 0.050 m/s when handling coarser or granular materials.

It must be remembered that if the filter is used in a negative pressure system, the volu- metric flow rate to be handled will be significantly higher, because of the very low pressure, and so the cloth area will have to be much greater than that in an equivalent positive pressure system exhausting to atmospheric pressure, in order to maintain the same face velocity. The same considerations will have to be given to the filters in a system that operates at a high altitude, and to any system in which high temperature material has to be handled.

Batch cycles

In batch conveying cycles, such as those associated with blow tanks, the air flow rate is not uniform with respect to time. At the end of the cycle, when the blow tank is just empty, a very large volume of air is stored under pressure in the blow tank and pipeline. The venting of this air, together with the regular compressor output for conveying, will result in a significantly higher filter duty at this time. This high air flow rate should be taken into account in the specification of the conveying line filter.

The resulting surge can be reduced by isolating the blow tank from the conveying line when it is empty, and venting the blow tank separately. If this is done, however, the filter on the material feed hopper above the blow tank will have to be appropriately sized for this intermittent high flow rate duty. Alternatively the supply from the air mover can be isolated when the blow tank is empty and the pressurized air in the blow tank can be used to purge the conveying line.