DECK FAULT SYMPTOMS

Some possible deck faults were covered in Chapter 16, where malfunctions of deck members, especially the feedback sensors, were described in terms of the effect they have on the operation of the syscon circuits. Those that upset picture reproduction or give rise to mechanical malfunction will not necessarily invoke a syscon action. Some common deck problems will next be described, with causes and corrective action:

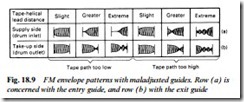

1. Inability to achieve correct envelope shape on entrance side: back-tension too low; worn video heads causing low tape penetration; faulty or maladjusted entrance guide(s); dirt on lead-in section of head rabbet

2. Tape path across guides wrong when envelope waveform correct: tape path biased by incorrectly aligned members beyond the guides, i.e. tilted stationary heads, bent tension pole, faulty pressure roller, incorrect reel height etc.

3. Tape creased during play or record: dirt or hairs on capstan or pressure roller; faulty or misaligned tape guides; foreign body or swarf along tape path

4. Tape damaged or chewed during threading or unthreading: incorrect braking action on spools; insufficient reel torque for take-up of slack; faulty mode switch

5. Slow or laboured fast-transport functions: slipping reel-drive idler or belt; faulty reel motor; excessive friction on worn lower drum; reel brakes incorrectly on

6. Wow and flutter on sound: where the capstan servo circuit is proved innocent, the capstan drive mechanics are implicated: faulty motor, bearings or drive belt should be suspected. Further possible causes are insufficient pinch-roller pressure (should be about 1.6 kg), faulty or ‘tight’ pinch-roller, bent capstan shaft and eccentric mounting of the head disc or drum, excessive take-up tension, oscillating back-tension pole. Many of these faults will give rise to picture problems, primarily:

7. Lateral wobble of picture: the visible equivalent of wow on sound. Where capstan or head-drum servo faults are not responsible, tightness of entry- and exit-guide rollers (VHS) on their shafts may be at the root of the problem. In such cases a squeak will often emanate from the offending guide. A faulty capstan or drum motor can give rise to the same symptom

8. Mechanical squeaking, especially in fast transport modes. In

VHS types ‘dry’ bearings are the usual cause; careful listening

will pinpoint the problem area, typically the bottom bearing of the capstan shaft or the reel-belt pulley

9. Replay picture rolling: symptomatic of a poor ‘entry’ r.f. envelope pattern, see (1) above and Fig. 18.9(a)

10. Excessive tape and head wear, misregistration of colour on tapes recorded elsewhere: back tension too high, check and adjust as described earlier in this chapter

11. Inability to match A/B output levels of new head assembly, and tracking control has differential effect on f.m. output levels of the two heads: this suggests that the heads are not operating in the same vertical plane, and may be due to the head disc/drum being tilted on its mounting platform during installation. Check for true running in the vertical plane

12. ‘Stop’ mode entered during threading or cassette transportation: jammed mechanics or mode switch. Dismantle and investigate