TAPE DECK MECHANICS AND SERVICING

The video tape deck is a high-precision ensemble of mechanical components, containing essentially the video head drum, a capstan, a reel drive system and a means of loading (threading) the tape around the head drum.

THREADING THE TAPE

All current video formats use co-planar cassettes in which the tape spools lie side by side. The feed spool is on the left when the cas- sette is correctly inserted into the machine; both spools are lifted just clear of the floor of the cassette shell as it is lowered onto the deck, which action also lifts its front plastic flap to permit the tape ribbon to be drawn out and loaded. There are two basic methods of loading tape: the travelling-guide system and the loading-ring system. The choice of loading system is a question of mechanical convenience rather than any inherent requirement of the format in use; provided the tape achieves the necessary wrap of the head drum (180° for standard VHS and some V8 types, more for ‘small head’ formats like VHS-C and V8 where the PCM facility is used) any type of loading system can be used.

Fig. 18.1 shows three stages in the tape-loading process of a typi- cal M-wrap VHS machine. A pair of loading poles enter behind the tape loop at the front of the cassette as it is lowered into the deck. When the loading phase begins the motor-driven arms move away from the cassette, drawing with them a loop of tape; the half-way point in the loading process is depicted in dotted outline. At loading completion the poles (adjustable tape guides in fact) locate in precision-machined V-grooves on cast pillars on each side of the head and are held in position by spring-loaded arms. At this loading-end point the loading motor stops as instructed by the loading-end switch via the syscon. The location of the moving guides in the V-grooves is very critical, since these guides define the path of the tape over the head drum; absolute accuracy and repeatability is essential for consist- ent tracking, a subject to which this chapter will return later. The advantage of a moving-guide M-wrap system is a relatively small and simple mechanism and short loading time.

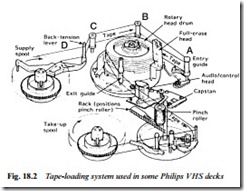

The alternative tape-loading method involves a moving pinch roller

and ‘U-wrap’ configuration: an example by Philips is given in Fig.

18.2. When the cassette is lowered onto the deck its shell embraces four tape guides and the pinch roller, all initially positioned behind the tape ribbon at the cassette front. To thread the tape the entry guide A moves out from the cassette to the left, pulling a loop of tape with it, and travels around the far side of the head drum; it comes to rest on a supporting bracket upstream of the full-erase head.

Guides B and C move into position during the threading phase to hold the tape ribbon clear of the drum. Simultaneously the pinch roller moves out from under the cassette and to the right, also taking a loop of tape with it, and comes to rest hard against the capstan shaft, pressed by a spring-loaded lever. These threading motions are driven by the threading/loading motor via a belt, pinions and a can- tilevered arm, and governed (via the syscon) by cassette-down and load-end microswitches, which take the place of the mode switch in conventional deck designs. The exit guide here is a simple stationary one bearing only on the top edge of the tape. Downstream from it, and thus positioned between the head drum and the cassette, is the audio/control/erase head assembly. Fig. 18.2 also shows the back- tension control system, in which the pole D bears on the outside (signal-carrying) face of the tape so that it does not have to start inside the cassette and tape loop as with M-wrap designs.

Tape loading around small heads

The VHS-C cassette is designed for use with loading pole/guides as described earlier for standard VHS practice. Here the M-wrap is extended into what amounts to an inverted omega ( ) wrap to embrace 270° of the head circumference as shown in Fig. 13.9. In small-drum VHS videorecorders, regardless of the size of cassette package used, the ‘steering slots’ for the two loading pole/guides extend round towards the back of the head drum where they locate in the V-grooves of a catcher block for precise positioning as shown in Fig. 18.3. Here the moving guides are transported by contra- rotating loading rings beneath the deck-plate; for use with small (C-type) cassettes a further (middle) pole, pivoted on the deck surface, springs up at a late stage in the loading process to prevent the outer threading loop contacting the right-hand side of the drum; the same function at the left is performed by the tension pole, to be described later.

Early Video 8 format machines use a combination of travellingarm and loading-ring techniques. A method used by Sony is illustrated in three progressive stages in Fig. 18.4. At (a) the cassette has just been inserted with the machine in standby mode. The first part of the loading process involves a pair of arm-mounted poles AA moving from their initial position behind the cassette’s front tape loop to resting-places on each side of the head drum, and drawing out a loop of tape. When this phase is complete (Fig. 18.4(b)) the loading ring itself begins to rotate anticlockwise; mounted on it is pole B which picks up the tape loop and carries it around the drum.

Loading is complete when the tape embraces 220° of the drum periphery as shown in Fig. 18.4(c). The ring-mounted tape-spacing rollers CC prevent the tape falling back on the drum, aided by arm- poles AA. The tape is now ready for record or play mode, impelled by capstan D pressing the tape against ring-mounted pressure roller E. The pole F is the back-tension regulator, shortly to be described.

Later designs of V8 decks use the M-loading arrangement of Fig. 18.1, with the difference that the deck section carrying the spool tables slides to and from the rest of the deck assembly during cassette load- ing and unloading.

The V8 cassette package has no internal tape guides – Table 18.1 gives further information on videotape cassette packages.