Particle melting

Particle melting is a form of material degradation that often occurs in pneumatic con- veying plant handling plastic type materials, particularly in pelletized form. If con- ventional pipeline is used, materials such as polyethylene, nylon and polyesters can form cobweb-like agglomerates. They are variously given names such as ‘angel hairs’, ‘raffia’, ‘snake skins’ and ‘streamers’.

They frequently cause blockages at line diverters and filters which require plant interruption to remove them. Equipment is generally installed at the terminating end of the system for this purpose. Such equipment is necessary because they also cause material rejection by customers, for the presence of these contaminants in the product is undesirable.

Mechanics of the process

The streamers are caused by the pellets impacting against the bends and pipe walls. A considerable amount of energy is converted into heat by the friction of the two sur- faces when they touch. If the surface of the pipe is smooth, the pellet will slide. This contact, though momentary, decelerates the particle by friction which is transformed into heat. This is generally sufficient to raise the temperature at the surface of the pel- let to its melting point. To a certain extent this is analogous to the thermal model pro- posed for erosive wear.

Influence of variables

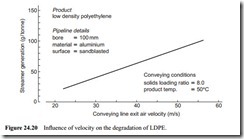

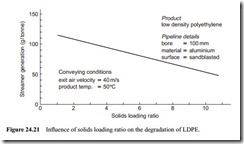

The onset of the formation of these angel hairs or streamers is the result of a combin- ation of conditions. Particle velocity is the most important, but it also depends upon the temperature of the pipeline, the temperature of the pellets, and the solids loading ratio of the conveyed material. The influence of conveying line exit air velocity for low density polyethylene is shown in Figure 24.20 and the influence of solids loading ratio for this same material is given in Figure 24.21 [9]. In each case the degradation of the material is expressed in terms of the mass of streamers and fines produced, in grams, per tonne of low density polyethylene conveyed.

Pipeline treatment

The formation of streamers and fines can be reduced quite considerably by suitably treating the pipe wall surface. A roughened surface is necessary in order to prevent the pellets from sliding. If the surface is too rough, however, small pieces will be torn away from the pellets instead, and a large percentage of fines will result. It will also have an adverse effect on the pressure drop, and hence on material conveying capacity.

Although the results presented in Figures 24.20 and 24.21 were obtained from tests carried out with pipe surfaces roughened by sand blasting, this treatment is not recommended as it will result in the generation of a large percentage of fines. Also, this roughness is relatively shallow in depth and an aluminium surface will wear so that the pipe must be retreated in six to twelve months [9].