First approximation design methods

Introduction

Pneumatic conveying system design is generally carried out either by using published mathematical models, or by using reliable conveying data that may be available. Mathematical models are often used when some confidence has been established in their suitability for a particular application, such as the conveying of a specified mater- ial over a given range of conveying conditions. They are, however, generally restricted to dilute phase suspension flow.

Conveying data is used extensively in situations where previous experience is avail- able, or from the results of tests specifically carried out for the purpose of system design. In cases where no previous experience of the material, or the range of convey- ing conditions required is available, then conveying trials are usually carried out in order to obtain the necessary data for system design. This is particularly so if dense phase conveying is required.

In many cases a quick approximate answer is all that is required initially, rather than a full design study, particularly if it is a feasibility study that is being carried out. A quick check on the expected throughput of a given system is often wanted, or the diameter of pipeline necessary for a given material flow rate may be needed. Very often the air requirements, in terms of supply pressure and volumetric flow rate, are wanted so that the approximate power required, and hence operating cost of the system can be evaluated, as illustrated at the end of the last chapter.

Two first approximation methods for pneumatic conveying system design are pre- sented that will provide a quick solution. One is applicable to both the dilute and dense phase conveying of materials while the other is only for dilute phase suspension flow. It must be emphasized that these are only first approximation solutions, as the title states, and that they should not be used for design purposes. They will, however, provide a reasonable guide to system parameters and can be applied very easily. A particular advantage of one method is that it can be applied to dense phase conveying as well as dilute phase.

Methods presented

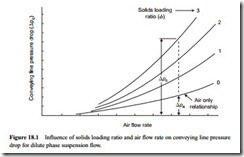

One method is based on the value of the air only pressure drop for the pipeline, which is a relatively straightforward parameter to evaluate. All the models and data likely to be required for such an evaluation are presented in Chapter 10, and several applica- tions of the equations are included in the case studies presented in the previous two

chapters. It would be recommended that the use of this method should be restricted to dilute phase suspension flow since the accuracy reduces at velocities below about 10 m/s and at solids loading ratios above 20.

The second method is based on the use of a universal set of conveying characteris- tics, comprising two sets of data. One relates to straight pipeline and the other to the bends in the pipeline. The data covers both dilute and dense phase conveying, but the dense phase conveying is only applicable to sliding bed flow and hence fine powdered mater- ials. It must be emphasized once again that these are strictly quick check methods and will provide only a first approximation solution. This is primarily because there is no reference anywhere in these procedures to the conveyed material.

Air only pressure drop method

Many of the basic models that are used in pneumatic conveying are mathematically correct, or very closely so. This is the case in evaluating conveying air velocities, for in most pneumatic conveying situations the volume occupied by the conveyed mater- ial will be negligible in comparison with that of the air.

Basic equations

The Ideal Gas Law relates the volumetric flow rate of the air to the pressure and tem- perature of the air. The volumetric flow rate of the air can also be expressed in terms of the conveying air velocity and the pipeline bore. These models, therefore, can be used quite reliably in gas–solid flow situations. Material mass flow rate can be intro- duced in terms of the solids loading ratio of the conveyed material. The solids load- ing ratio is a parameter that is often known approximately, and in these cases quite simple equations can be derived equating the variables.

Solids loading ratio

Solids loading ratio, ¢, is defined as the ratio of the mass flow rate of the material con- veyed, to the mass flow rate of the air used to convey the material and was presented in the introductory chapter with Equation (1.3). This is a dimensionless ratio and is a particularly useful parameter since its value remains constant along the length of a pipeline, regardless of the air pressure and temperature, and conveying air velocity. It is presented here as Equation (18.1):

where ¢ is the solids loading ratio (dimensionless), m· p, the mass flow rate of material (tonne/h) and m· a, the mass flow rate of air (kg/s).

The Ideal Gas Law

Air mass flow rate is not always a convenient parameter in this work and air flow rate is often better expressed in volumetric terms. The Ideal Gas Law, for a steady flow situation, however, presented in Equation (9.4), can be expressed in terms of air flow rate:

This is the actual volumetric flow rate. Since air and other gases are compressible, volumetric flow rate will change with both pressure and temperature. It also means that the conveying air velocity will vary along the length of a pipeline. A full explanation and analysis of this was included in Chapter 9.

Derived relationships

The three equations presented above can be considered as being exact equations, and so any combination of these equations will similarly produce precise relationships. Although these equations include all the basic parameters in pneumatic conveying, they will not produce design relationships. This is because they do not include the necessary fundamental relationships between material flow rate, pressure drop and conveying air velocity. Combinations of these three equations, however, produce equa- tions that can be usefully used to check system designs. They will also provide a good basis for the inclusion of design relationships.

Material flow rate

By substituting Equation (18.3) into (18.2) and then into Equation (18.1) and re-arranging gives:

For a given material flow rate and conveying conditions, the diameter of the pipeline is generally required. An alternative arrangement of Equation (18.4) gives:

Conveying line pressure drop

An alternative arrangement, in terms of the pressure required to convey the material gives:

Reference conditions

The variables in these equations can be taken at any point along the pipeline. In the case of air pressure and velocity, however, these are generally only known, with any degree of accuracy, at the very start and end of a pipeline. Since the conveying line inlet air velocity is probably the most critical parameter in system design it is generally conditions at the material feed point, at the start of the pipeline, that are used for this purpose.