PIPE FLOW CALCULATIONS

Compressible gas flow

All gases are, by definition, compressible and their flow pattern is governed by very complex mathematical relationships. The accurate determination of the flow characteris tics of such a medium can be extremely difficult. The aerodynamicist is concerned with the nature of air flow in a completely free medium where the solid boundaries are so far away as to be irrelevant to the solution of the flow problem; his main interest is in finding information about the local pressures and the flow velocities. The pneumatic engineer on the other hand is concerned primarily with the flow behaviour in a pipe. He wants to determine the average flow velocities and pressure drops in pipes of different sizes and materials, and the effect of putting in valves and fittings. He is less concerned with the details of the flow patterns across a pipe diameter or around the complex geometry of a valve. It is quite sufficient for him to know how much pressure is available to him at the end of a pipeline to operate a piece of equipment. To secure this limited objective, major simplifications to the theory are permissible.

This chapter is intended to be of help to the designer in estimating how much air (or other gas) can be expected to flow through a pipe. The aim is to supply practical answers; so, where assumptions can be made which produce results accurate enough for engineering purposes, those assumptions are indicated. The subject is not one which can be relied upon to give precise answers, so in this, as in many topics in pneumatics, there is no substitute for carrying out tests on an actual installation. In planning a layout for a factory or other form of fixed installation, the designer is well advised to work with generous factors of safety, not only to allow for uncertainties in the analysis but also to cater for future expansion of the system.

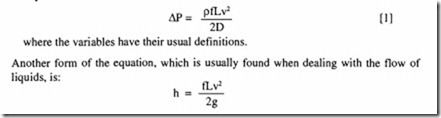

A determination of the pressure drop requires a knowledge of the relationship between pressure and volume. This is not easily determined in a particular case, but it is usual to consider two extremes, which are the same two as were considered for compression of air, namely isothermal and isentropic. Isentropic flow (or more accurately, in this instance, adiabatic since we are dealing with an irreversible process) applies to short, well insulated pipes. Isothermal is the more usual assumption, firstly because it is easier to analyse, but also because it more closely represents the actual situation in pipelines, where the air quickly reaches the ambient temperature and remains there, even when the pipes are well lagged. The descriptions isothermal and isentropic would have no relevance unless the fluid were compressible, that is unless it were possible to define a relationship between its pressure and its volume. It is usual to study first the formula for pressure drop that would apply to an incompressible fluid because it turns out that this applies equally well to many important cases of compressible flow. This equation is known as the Darcy formula or the Darcy-Weisbach formula:

In this formula h is the loss of head in metres. The concept of a head loss is readily understood in liquids, where pressure can be equated to the height of a liquid column. In gases it is not so relevant. The preferred relationship, therefore, is equation [1].

The variable f is known as the Darcy friction factor, which has to be obtained experimentally. The formula applies whether the flow is laminar or turbulent, but always with a value off appropriate to the flow regime. Fortunately, a large number of tests have been done on pipes of various materials, sizes and internal roughnesses, so it is possible to look up the value off on a chart when certain other parameters are known. The main factor governing the value off is the Reynolds number for the flow. It does not matter whether the fluid is a gas or a liquid; if the Reynolds numbers are the same, the value of f will be the same.