HEAT RECOVERY

Heat exchangers have been discussed in an earlier chapter. This chapter discusses how some of the heat generated during compression can be utilised for other purposes so as to improve the overall economy of the installation.

Many, if not most, of the industrial compressed air systems in use in the U.K. have been designed with little regard to economy of operation. Initial first cost is often the prime consideration, with little regard given to the possibilities of integration within the overall energy needs of the factory. Frequently as the needs of the factory expand, organic growth of the air system results in a further deterioration of what may have been ill considered at the outset.

Types of compressor cooling

There are three basic types of compressor cooling: external supply;

air cooled radiators;

water cooled heat exchangers; cooling towers.

External supply

Water from the sea, rivers, wells or the mains water authority are possible external sources of cooling. It will only rarely be possible to take advantage of these sources and rarer still will the heat extracted be usable or recoverable, although it is possible to imagine circumstances where some use can be made of it such as in fish farming or horticulture. Heating of the incoming mains water can be used to provide a supply of wash water, although getting the correct balance between supply and demand may be difficult.

Air cooled radiators

Water is recirculated without contamination or loss. Ifthe compressor is oil-flooded there may be a heat exchanger between the oil and the cooling water circulating through the radiator. This is a very common form of cooling, the main disadvantage being that extra power is needed to drive the fan. It is hardly practical to cool the water to below I 0°C above ambient, without extravagant use of fan power and a large radiator.

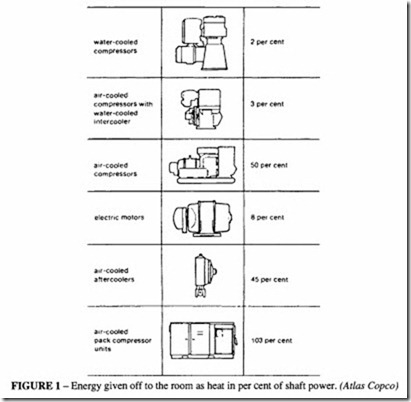

If a compressor set is situated on its own room, the heat generated will pass into the air in the room and has to be removed by a fan. Figure 1shows the heat given off by a selection of different types of compressor. In a compressor that is cooled by an external water cooler very little of the heat passes into the room (2% in Figure 1). Note the rather surprising figure of 103% for a freestanding compressor. This figure takes account of the extra fan power to drive the aftercooler. The ventilation of the room must be sufficient to ensure that the heat exchange works correctly and that no damage is done to the other equipment in the room. Insufficient cooling shortens the life of the electric motor.

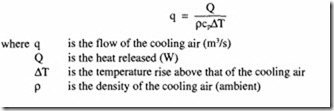

To estimate the ventilation flow needed the following relation may be used.

A typical heat flow diagram is presented in Figure 2; the actual heat flow will depend on the particular circumstances.

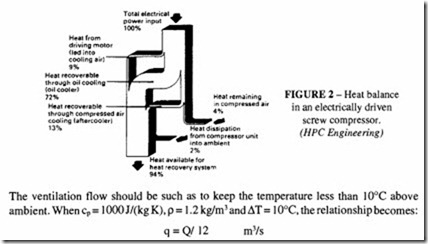

Almost all the heat can be passed into heating the air in the adjacent rooms (or even further away through insulated heating ducts). This heat is only valuable for winter heating

and has to be rejected to outside in summer, as in Figure 3. A heat recovery unit of this kind would incorporate thermostatically operated shutters.

Water cooled heat exchangers

A more versatile use of the heat is a combination of water heating and hot air, the proportions of the two varying according to the factory installation. In Figure 2, which applies to an oil-flooded screw compressor, a maximum of 72% is recoverable for the production of hot water and a minimum of22% for the production ofhot air. The hot water can be produced at 70°C, which can be further boosted by an extra heating coil. It is unlikely that there will, at all times, be a balance between heat produced and heat used, so the control system must incorporate a means for diverting the water flow and ensure that adequate cooling of the compressor is always available. Some of the heat may have to be rejected to ambient or passed into the hot air.

Central heating is needed during the summer months only so the yearly savings have to be calculated on 6 to 8 month basis if that is the main use to which the heat is put. As well as central heating, hot water can be sent to wash rooms or used for product cleaning and process uses such as galvanising. The heat exchanger can be as simple as the industrial equivalent of a domestic hot water tank in which case hot water is produced at a maximum of 55°C. For a rather more efficient package a plate heat exchanger can produce water at 70°C. the temperature quoted should not be taken as other than indicative of the possibilities. Actual temperatures need to be calculated when the cooling requirements of the compressor are known.

If any danger of water pollution must be avoided, the use of a safety heat exchanger is

recommended. This is a type of exchanger, either tube or plate, incorporating a buffer space between the two flow elements and draining grooves which allow pollution to flow to the outside. See chapter on Heat Exchangers and Coolers.

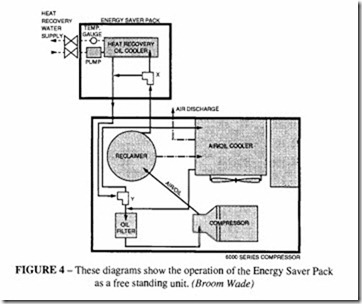

An example of a system of heat reclamation is shown in Figure 4, which illustrates an Energy Saver Pack (ESP). Using this pack both space heating and water heating are possible. The Energy Saver Pack is supplied as a stand-alone unit or incorporated into the compressor housing.

The following calculation is typical of the savings that are possible which the ESP:

There are other unquantified savings such as the space heating and the unused capital cost of the water heating equipment.

Cooling towers

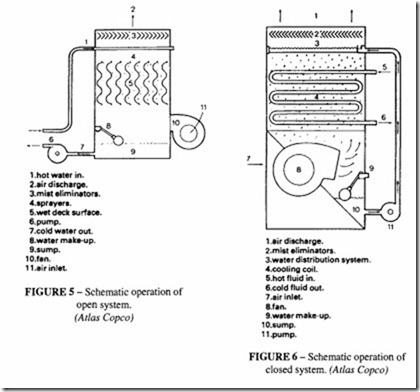

This is another form of cooling, which can also be used in compressor installations. Cooling is achieved by spraying hot water over a wet surface while air also passes over the surface. Hot water enters the top of the cooling tower and comes into contact with moving air as it passes over the wet surface and falls into the collecting sump.

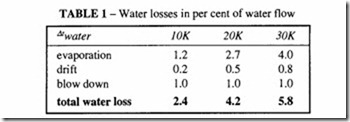

The major cooling effect is due to evaporation, so the performance depends upon the cooling load imposed and the wet-bulb temperature of the incoming air. Cooling towers can cool to within 3°C of the wet bulb temperature. Water is lost through evaporation, drift and blow-down, as in Table I.

Two types of cooling towers are available, open and closed. They are illustrated in Figures 5 and 6.

The open type is prone to contamination as the air and fresh water enters the tower. The closed type can accept either oil or water in the circuit with no risk of contamination and is a little more complicated.

It is not possible to reclaim the waste heat from a cooling tower. There are, however, circumstances in which a cooling tower would form part of a heat reclamation circuit. No heat recovery unit is so well balanced that the total heat generated in the compressor is available for use and in this instance the extra heat may be extracted in a tower.

Moisture separators

All heat exchangers need to incorporate a means of draining the water which is condensed out from the cooled air. Most water separators contain an automatic feature which discharges the condensed liquid. These are discussed in detail in the section on Air Treatment.