BEAM FOCUS SERVO

The objective lens has a very small depth of focus, typically less than 2 microns. In order to maintain correct focus on the pit surface in the face of tolerances in disc manufacture and mounting (and slide height) a servo system is required to drive the lens vertically. The lens assembly itself is mounted on a moving coil which moves in the annular gap of a permanent magnet, the assembly being very similar to the centre section of a moving-coil loudspeaker. Lens position is proportional to the current in the moving coil. The coil forms one element of a closed-loop servo system.

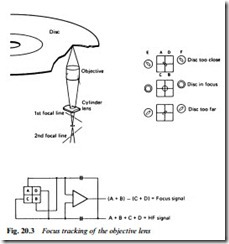

The combination of objective lens and cylindrical lens forms (for the return path only) an astigmatic lens, whose characteristic is that a perfectly focused circular light spot will render a circular image, whereas elliptical images will result from out-of-focus circular light spots. The angle of the major axis of the ellipse produced depends on the direction of defocusing, as shown in Fig. 20.3. A group of four photodiodes ABCD is arranged in quad formation and placed at a distance from the cylindrical lens such that with the disc in perfect focus all four diodes receive equal light, and pass equal current. If the focal point should fall short of the disc the circular spot closes

down to an ellipse whose light falls mainly on diodes C and D; their current increases while that in diodes A and B decreases. The result- ing imbalance is detected, amplified and turned into a current for passage through the objective lens coil in the correct sense to reduce the focus error. If, alternatively, the focal point falls beyond the disc surface, the narrow ellipse-image falls across diodes A and B whose current increases at the expense of that in C and D, whereupon the objective lens is driven by the servo amplifier to restore correct focus, signalled by exact balance in the quadrant photodiode matrix.

Although the maximum vertical movement of the objective lens is limited to about 150 microns, its response time is fast enough to cope with the changes in effective disc height which vary mainly at disc- rotation rate of between 25 Hz and 9 Hz.