Theory of two level systems

Some of the concepts in the theory have been advanced by the FPC and are reproduced here, because they illuminate some of the important features of compressed air operation.

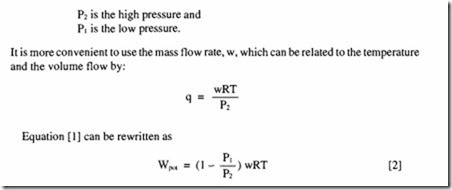

The first concept is that of potential power. Potential power is the useful power available in a compressed air supply, calculated on the assumption that the only available power is non-expansive. This assumption gives the relationship:

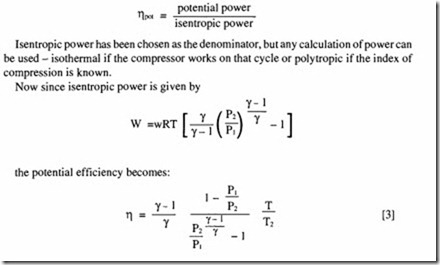

Tis normally equal to Tz, but the expression indicates that if the air can be used at a higher temperature than ambient, the efficiency is improved. This is rarely likely to be possible in practice, but if circumstances are such that it can be used in that way, there are advantages to be gained. The second conclusion to be drawn from this expression is that the efficiency is a function of pressure ratio.

A plot of the potential efficiency is given in Figure I.

On the same figure is a plot of the overall efficiency measured from experiments performed at FPC on a modified vane compressor. The overall efficiency, taking into account mechanical losses in the compressor drive, is rather less than the potential efficiency.

When comparing theoretical efficiency with the overall efficiency, it appears that the mechanical efficiency alone is of the orderof67%. On the face of it this seems rather lower than one would expect, but the values are obtained at an early stage in the development of the concept, and it is likely that they would improve with experience.