The three important characteristics of DC generator are

1. Open circuit characteristic or Magnetization curve or No – load saturation Curve

Open circuit characteristic is the relation between the No-load generated emf in the armature, and the field exciting current at a fixed speed. It is the magnetization curve for the material of electro- magnets. It is same for separately excited or self excited machine.

2. Internal or total characteristic

This characteristic curve gives the relation between the emf generated in the armature and the armature current.

3. External characteristic

This gives the relation between the terminal voltage and the load current. This characteristic takes into account the voltage drop due to armature circuit resistance and the effect of armature reaction. This characteristic is of importance in judging the suitability of generator for a particular purpose. This characteristic is also referred to as performance characteristics or voltage regulating curve.

The circuit diagram for obtaining the OCC is shown in figure 1.9. Irrespective of the type of the DC machine, namely, shunt, series, compound, the shunt field winding is disconnected and excited from an external source.

As iron is unsaturated under low excitation current condition, emf increases as flux increases with increase in excitation current. As the field current increases further the iron starts saturating, the emf will not increase proportionately as the flux is not varying proportionately with the current. This is shown by the knee ‘pq’ of the characteristic curve shown in figure 1.10. A further increase in field current leads to saturation of iron and the flux remains almost constant and hence the induced emf will also remain constant. This is shown by the region ‘qr’ in the figure1.10. Figure 1.10

CRITICAL RESISTANCE FOR SHUNT GENERATOR

When the armature is rotating with armature open circuited, an emf is induced in the armature because of the residual flux. When the field winding is connected with the armature, a current flows through the field winding ( in case of shunt field winding, field current flows even on No-load and in case of series field winding only with load) and produces

additional flux. This additional flux along with the residual flux generates higher voltage. This higher voltage circulates more current to generate further higher voltage. This is a cumulative process till the saturation is attained. The voltage to which it builds is decided by the resistance of the field winding as shown in the figure 1.11. If field circuit resistance is increased such that the resistance line does not cut OCC like ‘om’ in the figure 1.11, then the machine will fail to build up voltage to the rated value.

The slope of the air gap line drawn as a tangent to the initial linear portion of the curve represents the maximum resistance that the field circuit can have beyond which the machine fails to build up voltage. This value of field circuit resistance is called critical field resistance. The field circuit is generally designed to have a resistance value less than this so that the machine builds up the voltage to the rated value.

CONDITIONS FOR VOLTAGE BUILD UP OF A GENERATOR

Following are the conditions necessary for the voltage build up of a self excited generator.

(i) Residual magnetism must be present.

(ii) For the given direction of rotation, the field coils must be properly connected to the armature so that the flux produced by the field current reinforces the residual flux.

(iii) Its field resistance must be less than the critical field resistance.

CRITICAL SPEED

Critical speed of a generator is that speed for which the field circuit resistance becomes the critical field resistance.

Relation between induced emf and terminal voltage will provide an insight into the performance of the machine. The terminal voltage of the machine under loaded condition reduces from the no-load induced emf value because of the armature circuit voltage drop and armature reaction. Further the contact drop of the brushes will have to be taken into account. Usually a brush contact drop of 1volt is considered for a brush. This will be constant throughout the operating range of the machine.

ARMATURE REACTION

The action of magnetic field set up by armature current on the distribution of flux under main poles of a DC machine is called the armature reaction.

When the armature of a DC machines carries current, the distributed armature winding produces its own mmf. The machine air gap is now acted upon by the resultant mmf distribution caused by the interaction of field ampere turns (ATf) and armature ampere turns (ATa). As a result the air gap flux density gets distorted.

Figure 1.13 shows a two pole machine with single equivalent conductor in each slot and the main field mmf (Fm) acting alone. The axis of the main poles is called the direct axis (d-axis) and the interpolar axis is called quadrature axis (q-axis). It can be seen from the Figure 1.14 that ATais along the interpolar axis as shown. ATa which is at 900 to the main field axis is known as cross magnetizing mmf. Figure 1.14 shows the armature mmf (FA) acting alone.

Figure 1.15 shows the practical condition in which a DC machine operates. Both the main flux i.e., ATf(Field mmf) and ATa (armature mmf) are existing. Because of bothmmfacting simultaneously,

there is a shift in brush axis and crowding of flux lines at the trailing pole tip and flux lines are weakened or thinned at the leading pole tip. (The pole tip which is first met in the direction of rotation by the armature conductor is leading pole tip and the other is trailing pole tip)

If the iron in the magnetic circuit is assumed unsaturated, the net flux/pole remains unaffected by the armature reaction though the air gap flux density distribution gets distorted. If the main pole excitation is such that the iron is in the saturated region of magnetization (practical case) the increase in flux density at one end of the poles caused by armature reaction is less than the decrease at the other end, so that there is a net reduction in the flux/pole. This is called the demagnetizing effect.

Thus it can be summarized that the nature of armature reaction in a DC machine is

(i) Cross magnetizing with its axis along the q-axis.

(ii) It causes no change in flux/pole if the iron is unsaturated but causes reduction in flux/pole in the presence of iron saturation. This is termed as demagnetizing effect.

The resultant mmf ‘F’ is shown in figure 1.16

Graphical picture of flux density distribution is shown in figure 1.17

(a) Layout of armature and field of 2-poles of a DC machine.

(b) Armature mmf and flux density distribution (brushes in geometrical neutral axis)

(c) Main field and resultant flux density distribution – shift (θ) in Magnetic neutral axis.

The cross magnetizing effect of the armature reaction can be reduced by making the main field ampere-turns larger compared to the armature ampere-turns such that the main field mmf exerts predominantcontrol over the air gap. This is achieved by

(i) Introducing saturation in the teeth and pole shoe.

(ii) By chamfering the pole shoes which increases the air gap at the pole tips. This increases the reluctance to the path of main flux but its influence on the cross-flux is much greater.

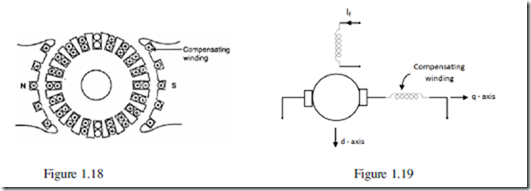

(iii) The best and most expensive method is to compensate the armature reaction mmf by a compensating winding located in the pole-shoes and carrying a suitable current.

COMPENSATING WINDINGS: the armature reaction causes the flux density wave to be so badly distorted that when a coil is passing through the region of peak flux densities, the emf induced in it exceeds the average coil voltage. If this emf is higher than the breakdown voltage across adjacent segments, a spark over could result which can easily spread over the whole commutator, resulting in the complete short circuit of the armature. Another factor which can cause severe over voltages to appear between commutator segments is the time variation of armature reaction and its associated flux due to sudden changes in machine load. If the load on the machine undergoes fast changes, the armature current Ia and armature flux/pole Φa changes accordingly resulting in statically induced emf in the coil proportional to dΦa/dt. This voltage along with dynamically induced emf worsens the conditions if both are additive. i.e., if the load is dropped from a generator or added to a motor.

The remedy for the above situation is to neutralize the armature reaction ampere-turns by compensating winding placed in the slots cut out in pole face such that the axis of the winding coincides with the brush axis as shown in figure 1.18 and 1.19.

The compensating windings neutralize the armature mmf directly under the pole which is the major portion because in the interpole region the air gap will be large. The remaining small portion of armature mmf in the interpole region is neutralized by the interpole windings. The number of ampere-turns required in the compensating windings is given by

Compensating windings though expensive, must be provided in machines where heavy overloads are expected or the load fluctuates rapidly.Ex. Motors driving steel mills.

DEMAGNETISING AMPERE TURN/POLE:

The exact conductors which produce demagnetizing effect are shown in Fig 1.20,Where the brush axis is given a forward lead of θ so as to lie along the new axis of M.N.A. The flux produced by the current carrying conductors lying in between the angles AOC and BOD is such that, it opposes the main flux and hence they are called as demagnetizing armature conductors.

CROSS MAGNETIZING AT/POLE

In the figure 1.21 Conductors lying in between the angles BOC and DOA are carrying the current in such a way that the direction of the flux is downwards i.e., at right angles to the main flux. This results is the distortion in the main flux. Hence, these conductors are called cross magnetizing or distorting ampere conductors.

When a DC generator is loaded, voltage drop occurs due to

1. The armature reaction – which causes the voltage drop because of demagnetization.

2. Armature circuit resistance – causes voltage drop in the armature.

Hence the terminal voltage of the DC generator will be less than the No-load induced emf.

LOAD CHARACTERISTICS or EXTERNAL CHARACTERISTICS

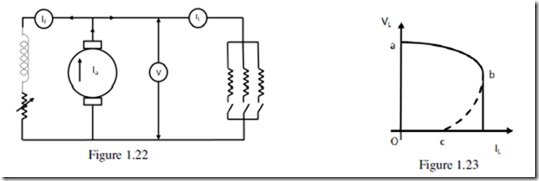

The circuit diagram for obtaining the load characteristics is shown in figure 1.22.

The generator is brought to its rated speed and rated voltage is built up and loaded gradually. The plot of terminal voltage vs load current gives the external characteristic which is shown in the figure

1.23. There are three reasons for the drop in voltage (‘ab’ in figure 1.23) as the load increases.

1) Armature resistance drop

2) Armature reaction drop

3) Drop in terminal voltage due to 1 and 2 results in decreased field current which further reduces the induced emf.

The portion ‘ab’ on the external characteristic curve is the working part of the generator. If the load current is increased further, it is found that the terminal voltage rapidly decreases and comes to zero which is nothing but short circuit. The drastic decrease in terminal voltage ‘bc’ is due to the severe armature reaction for the large load current and increased armature resistance drop. Thus any increase in load current beyond the point ‘b’ results in terminal voltage drastically reducing though there would be some induced emf due to residual magnetism.

INTERNAL OR TOTAL CHARACTERISTICS

Internal characteristics give the relation between induced emf E and armature current Ia. In a DC shunt generator Ia = IL + If and E = V + Ia Ra. Hence, E vsIa curve can be obtained from V vs IL characteristic curve as shown in the above figure 1.24. In this figure- ‘ab’ represents the external characteristics. The field resistance ‘OB’ is drawn. The horizontal distances from ‘oy’ line to line ‘OB’ give the values of field currents for different terminal voltages. If these distances are added horizontally to the external characteristic curve ‘ab’, then we get the curve for total armature current, i.e., ‘ac’. The armature resistance drop line ‘or’ is plotted. For any armature current ‘ok’ armature voltage drop IaRa = ‘mk’. If these drops are added to the ordinates of the curve ‘ac’, then we get the internal characteristic curve ‘at’.

If the load resistance is decreased then armature current increases upto certain value and then, any decrease in any further decrease in load resistance results in decrease in terminal voltage which is shown in figure 1.25. This is due to excessive demagnetization of main poles.

SERIES GENERATOR CHARACTERISTICS

In series generator field windings are in series with the generator. Hence, they carry full load current.

As the load is increased, Ia increases and hence generated emf also increases as shown by the curve ‘Ob’ in figure 1.27. If the excitation current necessary to neutralize the demagnetizing effect of armature reaction at full load is added, we get the internal characteristics. If IaRa drop is subtracted from the internal characteristics, we get the external characteristics.

It will be noticed that the series generator has the rising voltage characteristics but at high load currents the voltage starts decreasing due to excessive demagnetization effects of armature reaction.

CHARACTERISTICS OF COMPOUND GENERATOR

The figure 1.28 shows the characteristics of compound generator. If the series field ampere turns are such as to produce the same voltage at rated load as at no-load then the generator is said to be flat compounded. If the series field ampere turns are such that the rated load voltage is greater than the no-load voltage, then the generator is

said to be over compounded. If the rated load voltage is less than the no-load voltage, then the generator is said to be under compounded.

Related posts:

Incoming search terms:

- explain characteristics of generator

- residual flux in dc generators

- the internal characteristics of generator is the curve between

- external characteristics of generator

- internal and external characteristics of dc generator

- characteristic of backup generator

- what is the nature of the speed -torque characteristics of a d c motor with constant excitation ideal no load

- magnetization and load characteristics of dc generator

- what do you mean by No Load saturation charateristics

- DC charecteristic of DC generator internal and external chara

- electric generators mail

- graph LOAD characteristics of dc compound generator

- various characteristics of shunt series and compound generator

- performance characteristics of a dc series generator

- operating charactrtistics of D C generator

- sketch the flux density distribution in the air- gap of a dc machine due to field MMF alone armature MMF alone and due to the resultant MMF

- magnetization characteristics of dc shunt generator

- load characteristics of dc shunt generator

- features of dc generator

- flux density of armature graph

- internal characteristics of dc generator

- external characteristics of dc shunt generator

- magnetization characteristics of dc generator

- explain the operation characteristics of a dc generator

- external characteristics of all dc generators

- characteristics of a dc motor and generator

- explain internal and external characteristic of dc generator

- explain the characteristic d c generator with diagram

- explain the characteristics of dc series generator

- external and internal characteristics of dc generator

- external characteristics of dc shunt gene

- charecteristics of a dc generator

- dc series generator open circuit characteristics

- why terminal voltage vs load current characteristics in dc shunt generator slopes downwards

- characteristic of dc shunt generator

- characteristics of D C genwrator

- characteristics of dc

- characteristics of dc generator and motor

- characteristics of dc generators with diagram

- Characteristics of Dc machines

- characteristics of dc shunt and series generator

- charector stick of d c generator

- crucial resistance in dc generator

- dc compound generators in characteristics images

- Dc generator and motor charactersicics

- dc generator characteristics#spf=1

- DC generator has terminal voltage verses load current characteristics which is

- dc genrator characteristic

- dc machine characteristics

- Dc series generator internal graph