Basic Principle

A.C. generators or alternators (as they are usually called) operate on the same fundamental principles of electromagnetic induction as d.c. generators. They also consist of an armature winding and a magnetic field. But there is one important difference between the two. Whereas in d.c. generators, the armature rotates and the field system is stationary, the arrangement in alternators is just the reverse of it. In their case, standard construction consists of armature

winding mounted on a stationary element called stator and field windings on a rotating element called rotor. The details of construction are shown in Fig. 37.1.

The stator consists of a cast-iron frame, which supports the armature core, having slots on its inner periphery for housing the armature conductors. The rotor is like a flywheel having alternate N and S poles fixed to its outer rim. The magnetic poles are excited (or magnetised) from direct current supplied by a d.c. source at 125 to 600 volts. In most cases, necessary exciting (or magnetising) current is obtained from a small d.c. shunt generator which is belted or mounted on the shaft of the alternator itself. Because the field magnets are rotating, this current is supplied through two sliprings. As the exciting voltage is relatively small, the slip-rings and brush gear are of light construction. Recently, brushless excitation systems have been developed in which a 3-phase a.c. exciter and a group of rectifiers supply d.c. to the alternator. Hence, brushes, slip-rings and commutator are eliminated.

When the rotor rotates, the stator conductors (being stationary) are cut by the magnetic flux, hence they have induced e.m.f. produced in them. Because the magnetic poles are alternately N and S, they induce an e.m.f. and hence current in armature conductors, which first flows in one direction and then in the other. Hence, an alternating e.m.f. is produced in the stator conductors (i) whose frequency depends on the number of N and S poles moving past a conductor in one second and (ii) whose direction is given by Fleming’s Right-hand rule.

Stationary Armature

Advantages of having stationary armature (and a rotating field system) are :

1. The output current can be led directly from fixed terminals on the stator (or armature windings) to the load circuit, without having to pass it through brush-contacts.

2. It is easier to insulate stationary armature winding for high a.c. voltages, which may have as high a value as 30 kV or more.

3. The sliding contacts i.e. slip-rings are transferred to the low-voltage, low-power d.c. field circuit which can, therefore, be easily insulated.

4. The armature windings can be more easily braced to prevent any deformation, which could be produced by the mechanical stresses set up as a result of short-circuit current and the high centrifugal forces brought into play.

Details of Construction

1. Stator Frame

In d.c. machines, the outer frame (or yoke) serves to Stationary armature windings stampings and windings in position. Low- speed large-diameter alternators have frames which because of ease of manufacture, are cast in sections. Ventilation is maintained with the help of holes cast in the frame itself. The provision of radial ventilating spaces in the stampings assists in cooling the machine.

But, these days, instead of using castings, frames are generally fabricated from mild steel plates welded together in such a way as to form a frame having a box type section.

carry the magnetic flux but in alternators, it is not meant for that purpose. Here, it is used for holding the armature special magnetic iron or steel alloy. The core is laminated to minimise loss due to eddy currents. The laminations are stamped out in complete rings (for smaller machine) or in segments (for larger machines). The laminations are insulated from each other and have spaces between them for allowing the cooling air to pass through. The slots for housing the armature conductors lie along the inner periphery of the core and are stamped out at the same time when laminations are formed. Different shapes of the armature slots are shown in Fig. 37.3.

The wide-open type slot (also used in d.c. machines) has the advantage of permitting easy installation of form-wound coils and their easy removal in case of repair. But it has the disadvantage of distributing the

Streetbike stator

air-gap flux into bunches or tufts, that produce ripples in the wave of the generated e.m.f. The semi-closed type slots are better in this respect, but do not allow the use of form-wound coils. The wholly-closed type slots or tunnels do not disturb the air-gap flux but (i) they tend to increase the inductance of the windings

(ii) the armature conductors have to be threaded through, thereby increasing initial labour and cost of winding and (iii) they present a complicated problem of end- connections. Hence, they are rarely used.

Rotor

Two types of rotors are used in alternators (i) salient-pole type and

(ii) smooth-cylindrical type.

(i) Salient (or projecting) Pole Type

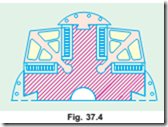

It is used in low-and medium-speed (engine driven) alternators. It has a large number of projecting (salient) poles, having their cores bolted or dovetailed onto a heavy magnetic wheel of cast-iron, or steel of good magnetic quality (Fig. 37.4). Such generators are characterised by their large diameters and short axial lengths.

The poles and pole-shoes (which cover 2/3 of pole-pitch) are laminated to minimize heating due to eddy cur- rents. In large machines, field windings consist of rectangular copper strip wound on edge.

(ii) Smooth Cylindrical Type

It is used for steam turbine-driven alternators i.e. turbo- alternators, which run at very high speeds. The rotor consists of a smooth solid forged steel cylinder, having a number of slots milled out at intervals along the outer periphery (and parallel to the shaft) for accommodating field coils. Such rotors are designed mostly for 2-pole (or 4-pole) turbo-generators running at 3600 r.p.m. (or 1800 r.p.m.). Two (or four) regions corresponding to the central polar areas are left unslotted, as shown in Fig. 37.5 (a) and (b).

The central polar areas are surrounded by the field windings placed in slots. The field coils are so arranged around these polar areas that flux density is maximum on the polar central line and gradually falls away

n either side. It should be noted that in his case, poles are non-salient i.e. they do not project out from the surface of the rotor. To avoid excessive peripheral velocity, such rotors have very small diameters (about 1 metre or so). Hence, turbo-generators are characterised by small diameters and very long axial (or rotor) length. The cylindrical construction of the rotor gives better balance and quieter-operation and also less windage losses

Related posts:

Incoming search terms:

- basic principle of alternator

- alternator basic

- basic principle of an alternator

- state alternator principle

- the stater of an alternator uses which tupe of slots

- principle of alternator

- slots in alternator

- principal operation of a alternator

- alternator

- alternator principles

- alternator principle

- types of slots in alternator

- the stator of an alternator rarely uses the slots

- Reason for Semi closed slots in alternator

- wholly closed slot in use motor

- state basic principle of alternator

- The armature of an alternator rarely uses

- type of slot in alternator

- the stator of alternator rarely uses

- the stator of an alternator rarely use slot

- the stator of an alternator rarely used slot

- advatages and disadvantages of wholly closed slotd

- open slot &cloe slot in armature

- alternator construction and priciple and function tamil language

- alternator pole shoes

- alternator priciple

- alternators principle

- alterntor operates basic pricipal

- basic princepal of alternators

- basic principle of alternator/

- basic principles of alternator

- box type frame salient alternator

- conductors images in alternator

- disadvantages of having a stationery armature of an alternator

- flemings right hand law useing elemantes

- fundamental principle on which alternators operate

- working principle of alternator