Optimizing existing systems

In the majority of cases optimization of an existing system will be achieved by reducing the amount of air used for conveying the material. The problem with existing plants, however, is the potential disruption of production, particularly if a change in conditions results in a pipeline blockage. A large degree of control, therefore, is required so that changes can be made gradually and their effects can be carefully monitored.

Control and instrumentation

Although reducing the speed of the blower can produce the additional benefit of a slight increase in delivery pressure, it is not very convenient in terms of control and gradual adjustment. An off-take to atmosphere in the air supply line between the blower and the point at which the material is fed into the pipeline provides much more flexibility.

This can easily be arranged by fitting a Tee-piece into the line, with a control valve on the off-take. If there is not already a pressure gauge on the air supply line one could be fitted at the same time, as this will be needed to record the air supply pressure, or conveying line pressure drop.

If a rotameter, or some other form of air flow rate measuring device, is also fitted so that the air is discharged through it to atmosphere, a measure of the air flow rate dis- charged will be obtained as well. As many valves have non-linear characteristics, a rotameter would be particularly useful in ensuring that the desired proportion of air was discharged. By this means it will be possible to exercise full control over the air flow rate and quite accurately determine the amount actually used for conveying. Once this off-take is installed, tests can be carried out on the plant with little disruption to production.

In most plants the supply or receiving hoppers are mounted on load cells, or have some other weighing mechanism, and so material flow rates can be determined rea- sonably quickly and accurately, whether conveying is continuous or batch-wise. By gradually opening the off-take valve a number of tests can be carried out, and if the air supply pressure and the material flow rates are recorded for each test, it will be pos- sible to construct a small part of the conveying characteristics. Depending upon the method of feeding the material into the pipeline it may be necessary to make adjust- ments to the feed rate so that this can be varied as well.

It is recommended that the amount of air by-passed to atmosphere should not exceed more than about 15 per cent of the total supply from the blower. When this point is reached the speed of the blower should be reduced to match the reduced air flow rate required before discharging any more air to the atmosphere. This is neces- sary to prevent the possibility of a surge in material feed from blocking the pipeline. A momentary increase in material flow rate will demand an increase in pressure, and if the off-take valve is wide open a much higher proportion of air will be lost than intended in the transient situation that follows. As a result the conveying line could be starved of air and the line could block.

Feeder considerations

Screw feeders and rotary valves are positive displacement devices and so the feed rate is unlikely to change. In this case an improvement in performance will be recognized in terms of a reduction in conveying line pressure drop. This, of course, will provide a perfectly valid alternative data point. If a significant reduction in conveying line pres- sure drop is achieved it would be recommended that the speed of the screw or rotary valve should be increased to give a higher material flow rate. This will then provide another data point.

By making gradual changes in air off-take, blower speed, and material flow rate, and determining the conveying line inlet air velocity at each stage, if should be pos- sible to establish the capability of a system without risk of disrupting production on an existing plant.

The use of a sight glass

Ideally some of the tests should be carried out with conveying air velocities as close to the minimum as possible. For this purpose it would be a distinct advantage if there was a short length of sight glass in the pipeline so that the material being conveyed could be observed. With a sight glass in the line it would be possible to detect when convey- ing was being carried out close to the minimum conditions, and so tests could be carried out in this region with much more confidence.

Such a sight glass should be positioned as close as possible to the point at which the material is fed into the pipeline, for as the conveying air expands through the line the velocity will be a minimum at the material feed point, as this is the point of minimum velocity. Ideally the sight glass should be in a straight length of pipeline and be a couple of metres from any bend or valve in the line. A sight glass in a vertical line is possibly better than one in a horizontal line, for minimum conditions are much easier to detect.

In a vertical line the flow is across the full bore of the pipe and at very low velocities some of the material will be observed to drop out of suspension, fall down past the sight glass, and be re-entrained in the conveying air. In some cases the material will start to build up on the wall of the sight glass. If all that can be seen is a blur it will be obvious that the conveying air velocity is far too high.

By carrying out tests over as wide a range of conveying conditions as can be achieved, it should be possible to obtain a reasonable indication of the nature of the conveying characteristics in the region of interest. If an improvement in material flow rate was indicated with a reduced air flow rate, the off-take valve could be shut and the speed of the blower could be reduced to provide the optimum value of air flow rate, and it is possible that an improvement in air supply pressure would result. If no improvement in material flow rate was achieved, the exercise would at least confirm that the material was already being conveyed under optimum conditions, and this would provide useful information about conveying air velocities and pressure drops so that the influence of alternative means of increasing the output could be assessed, such as using a larger bore pipeline.

Off-take systems

Figure 21.1 shows how part of the air supply can be discharged to atmosphere so that it is not used for conveying the material in the pipeline. This is a sketch of a simple positive pressure conveying system and shows the off-take positioned between the air mover and the material feeding device.

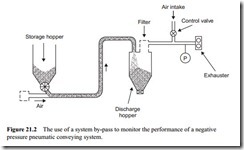

In a negative pressure system it would be positioned between the filtration unit and the exhauster. Air is drawn into the system and so it is an air intake rather than an off- take. By this means the exhauster discharges the rated air flow, but less air is drawn through the pipeline to convey the material. A sketch of a negative pressure system with such a Tee-piece and valve is given in Figure 21.2.

The same optimizing procedure can be applied to combined positive and negative pressure systems (see Figure 2.5). Each part would have to be assessed individually and be provided with its own Tee-piece and valve. Only if both parts of the system were to be found to be equally over-rated would it be possible to change the speed of the blower to provide the desired air flow rate. If there is any in-balance, one Tee-piece would have to be set and left open.