Precautions against explosions

The precautions to be taken against electrical ignition of flammable atmospheres are described in Chapter 15.

Preventive maintenance and safe systems of work Preventive maintenance A common cause of the types of accidents described in this chapter is electrical systems which are not maintained and which are allowed to degrade into a dangerous condition. Typical examples of dangerous features arising from lack of maintenance are:

● enclosures and assemblies that are broken, allowing access to live parts, or in which the seals have degraded, allowing the ingress of dusts and liquids

● cables with damaged sheathing and basic insulation or with mechanical damage that compromises the protective conductors or creates the conditions for arcing as a result of insulation failure

● corrosion of exposed metallic parts

● low electrolyte levels in battery-based tripping supplies or uninterruptible power supplies

● low levels of insulating oils in switchgear, or insulating oils that have degraded insulating properties

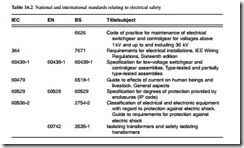

Advice on the preventive maintenance of low-voltage distribution systems is published in BS 7671. The IEE publishes guidance on the maintenance of electrical equipment, see references 16B and 16C. Advice on the preventive maintenance of high-voltage systems is available in BS 6626 (see Table 16.2). Manufacturers’ literature should also provide information on the maintenance strategies for equipment supplied.

Safe systems of work

Safe working practices on electrical systems comprise precautions on equipment that has been made dead and precautions during live working. These are covered separately in the following sections.

Safe isolation procedures

Most electrical work should be done on systems that have been made dead and on which precautions have been taken to prevent them from being re-energized while work is going on. The generic safe isolation procedure is as follows:

A. Identify the circuit or apparatus on which work is to be done and all possible points of supply.

B. Disconnect the supply and secure the point of isolation, typically by using pad- locks to lock devices in the off position, and post caution notices at the point(s) of isolation to warn that work is being done on the disconnected circuit(s).

C. At the point of work, prove the conductors are dead using a suitable voltage indicator, such as test lamps. The voltage indicator must be proven to be ser- viceable immediately before and after the conductors have been tested for voltage.

D. For high-voltage equipment, apply earths to the conductors on which work is to be done.

E. Ensure that the persons carrying out the work on the isolated systems are aware of the scope and limitations of the work to be done.

Safe isolation procedures such as these should only be carried out by competent people who have been trained to implement them and who are familiar with the equipment involved.

In the cases of high-voltage systems and high fault level low-voltage systems, it is standard practice that the safe isolation procedure is formalized using a safety document, such as a Permit to Work. Where systems that have been isolated under a Permit to Work have to be energized to allow testing to be carried out, the testing is often authorized and described in a safety document called a Sanction for Test. Details on safety documents are published in BS 6626 and in reference 16D.

Live working practices

Live working is most commonly carried out during fault finding and testing, particu- larly on low-voltage systems. Some more specialized live work is carried out by specialists who have received in-depth training. Live work should normally only be carried out when it can be argued that it is unreasonable to make the conductors dead, and that the risks are acceptable, and only if precautions can be implemented to prevent electrical accidents. Common examples of live working activities are:

● live cable jointing and meter changing on low-voltage distribution systems

● phasing out high-voltage conductors on switchgear, such as circuit breakers and ring main units

● ‘rubber glove working’ on 11 kV overhead distribution lines, a technique in which linesmen wearing insulating gauntlets and working in cradles on insulated booms on mobile elevating work platforms work on live plant that has been covered with suitable insulating materials

● live line working on the transmission grid overhead lines at voltages from 132 kV upwards, a technique in which the linesman carrying out the work is raised to line potential

The main hazards during live work are electric shock and burns from direct contact with live conductors and flashover/arc burns due to insulation failure.

In order to prevent these types of injuries, live work should only be carried out when it is essential and when it is unreasonable for the conductors to be made dead, and when the risks are acceptable. In the event of live work being undertaken, precautions against injury must be adopted.

The most important precaution is to ensure that the live work is carried out by people who are competent for the task or who are being closely supervised by

somebody who is competent. This means that they must have been trained in the task and been assessed as being competent, and must understand the system on which they are working and the means of protecting against injury. They must be provided with the appropriate tools, test equipment and personal protective equipment. Live work should only be undertaken after a risk assessment has been conducted, the risks identified and the appropriate safety precautions have been determined.

The types of precautions that can be taken are as follows:

A. The area of the work activity should be cordoned off or otherwise delineated and protected to prevent the workers being distracted or disturbed. Warning signs should be posted.

B. Only tools and test equipment that are suitable for the job should be used.

Test equipment probes should be fused or otherwise protected against short circuit or overload, should have finger guards to stop the fingers slipping down the probe onto the live conductors, and there should only be 2–4 mm of metal exposed at the tips of the probes. Care should be taken to ensure that the test equipment itself, such as Class I oscilloscopes and signal generators, does not introduce additional hazards.

C. Where necessary, flexible insulating materials should be used to shroud off metalwork in the vicinity of the work that may be at other potentials, including earth.

D. Where it will contribute to risk reduction, the live worker should be accompanied.

E. Appropriate and well-maintained personal protective equipment should be worn, such as antiflash clothing and eye protection where there is a risk of flashover or arcing.

More detailed information of safety during live working is published in references 16A and 16D.

Standards