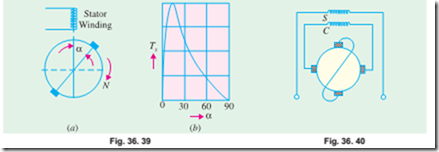

Compensated Repulsion Motor

It is a modified form of the straight repulsion motor discussed above. It has an additional stator winding, called compensating winding whose purpose is (i) to improve power-factor and (ii) to pro- vide better speed regulation. This winding is much smaller than the stator winding and is usually wound in the inner slots of each main pole and is connected in series with the armature (Fig. 36.40) through an additional set of brushes placed mid-way between the usual short-circuited brushes.

Repulsion-start Induction-Run Motor

As mentioned earlier, this motor starts as an ordinary repulsion motor, but after it reaches about 75 per cent of its full speed, centrifugal short-circuiting device short-circuits its commutator. From then on, it runs as an induction motor, with a short-circuited squirrel-cage rotor. After the commutator is short-circuited, brushes do not carry any current, hence they may also be lifted from the commutator, in order to avoid unnecessary wear and tear and friction losses.

Repulsion-start motors are of two different designs :

1. Brush-lifting type in which the brushes are automatically lifted from the commutator when it is short-circuited. These motors generally employ radial form of commutator and are built both in small and large sizes.

2. Brush-riding type in which brushes ride on the commutator at all times. These motors use axial form of commutator and are always built in small sizes.

The starting torque of such a motor is in excess of 350 per cent with moderate starting current. It is particularly useful where starting period is of comparatively long duration, because of high inertia loads. Applications of such motors include machine tools, commercial refrigerators, compressors, pumps, hoists, floor-polishing and grinding devices etc.

Related posts:

Incoming search terms:

- repulsion motor

- compensated repulsion motor

- repulson motor

- explain compensated repulsions motors

- commensated replusion motor

- use of compensated in repulsion motor

- Small Moter video downlod

- repulsion motor with diagram

- purpose of stator winding in compensated repulsion motor

- losses in repulsion motor

- diagram of repulsion motor

- compesated repusion motor

- compensating repulsion motor

- compensated and uncompensated motors

- what is repulson moter