TEST EQUIPMENT

In effect the test equipment forms the eyes and ears of the engineer, who depends on its accuracy and reliability to interpret what is happening in the circuits being dealt with; but it is important to understand the limitations of the test gear and the effect of its use on circuit operation. Brief descriptions of the main classes of test instrument follows.

Multimeter

The traditional analogue multimeter is based on a sensitive large- scale moving-coil meter whose dial is calibrated in ohms, volts and milliamps, the latter two usually on a 3- and 10-full-scale deflection (f.s.d.) basis. Except for resistance readings it is a passive device, draw- ing energy from the circuit under test, the amount depending on the sensitivity of the moving coil. A basic 50 μA f.s.d. movement offers a sensitivity of 20 kΩ per volt on d.c. ranges, and the best known high-quality multimeter (AVO models 8, 9 and derivatives) have this specification, though more sensitive types, up to 100 kΩ/V, are avail- able. The ranges of these types of meter are typically d.c. voltage from3V to3 kV f.s.d.; a.c. voltage ditto, but at lower sensitivity; d.c. current from 50 μA to 10 A f.s.d.; a.c. current from 10 mA to 10 A f.s.d.; and three resistance ranges with which measurement between 1 Ω and 20 MΩ can practically be made. Lesser meters do not offer such wide ranges, especially of current measurement, but in all cases the ranges offered are quite adequate for servicing all types of consumer equipment. Since most general-purpose multimeters are subjected to accidental overload from time to time, a reliable cut-out/ protection system is important. The AVO types score particularly here, with their electromechanical safety cut-out.

The passive multimeter is the most used general-purpose instrument in service work, but it has some limitations. Its accuracy is generally between ±1% and ±7% of f.s.d. depending on type and circumstances. Its loading effect on the circuit under test depends entirely on the impedance of that circuit. In high-impedance circuits an active meter must be used to prevent loading and thus achieve an accurate reading. It contains an amplifier to drive the meter movement, and typically has an input impedance of 10 MΩ on all ranges.

This increase in sensitivity permits provision of much wider measurement ranges, which may now extend down to 10 mV a.c. and d.c., and up to 200 MΩ for resistance tests. On low a.c. voltage ranges it is important to bear in mind the effect of mains hum and time-base- radiation pick-up, however, especially when working on high- impedance circuits.

Digital meter

While the active multirange analogue meter overcomes the loading effect of ordinary multimeters, its intrinsic accuracy of reading is no better. A digital multimeter has much greater accuracy and higher resolution. It consists basically of a high-impedance precision volt- age divider for range selection, an A−D converter and a digital read- out system using a neon, LED, liquid-crystal or fluorescent display similar to those on videorecorder front panels. A typical instrument for general service work has a 3^ digit display whose maximum reading is 1.999 and decades thereof.

Digital multimeters (DMMs) come in various sizes and specifica- tions; in all cases their greatest virtue is accuracy, which ranges from ±1% in inexpensive types to ±0.02% (two parts in 104) in precision 4^ digit bench instruments. Portable types are pocket size and offer typically 500 hours’ operation between battery changes due to a low- consumption LCD display. At the other end of the scale, mains- powered instruments have bright light-emitting displays and wide ranges – 29 or 30 ranges may be offered, though resistance ranges seldom go beyond 20 MΩ. Some sophisticated types have auto- ranging, in which it is only necessary to set the function (i.e. voltage, current, resistance) whereupon the level is automatically sensed, and units (mV, V; μA, mA, A; Ω; kΩ, MΩ) are displayed alongside the readout digits, together with an indication of polarity on d.c. ranges. DMMs are not easily damaged by the sorts of overload which would ruin analogue meter movements, but are vulnerable to accidentally applied pulse and e.h.t. voltage.

The main drawback with digital meters is the confusing display (known as fruit machine effect) where the measured quantity is not constant, i.e. a voltage line with superimposed mains hum ripple. The instrument samples the input condition several times per second, and if each ‘update’ is different, readings are difficult to take. Analogue meters make no such confusion, settling at the mean level of the vary- ing quantity being checked.

Oscilloscope

While the multirange meter is the most used test instrument, the oscil- loscope is perhaps the most useful. Basically it provides a continu- ous plot of voltage against time, so that period, amplitude and waveshape of the applied input can be read off against a calibrated graticule over the screen. A typical bench oscilloscope for general service work is pictured in Fig. 23.1.

The most important section of the oscilloscope is its Y amplifier, to which the signal is applied – two are incorporated in dual-trace types, which are essential to modern service practice. For general TV and video work, a bandwidth of 10 MHz is the minimum require- ment; 20 MHz is better if it can be afforded. The second important factor is Y-sensitivity, invariably measured in millivolts per screen division: the screen is typically divided into 1 cm squares. A minimum sensitivity of 10 mV/div. is the requirement, though 5 mV/div. is bet- ter, and 2 or 1 mV/div. better still. In all ’scopes a calibrated step- attenuator is used to set Y-gain, and at its maximum setting (greatest attenuation) a figure of 10 V/div. is typical. Normally the Y amplifier is a.c.-coupled via a large internal capacitor at the input socket to keep the trace centred on the screen, but maintain response down to about 10 Hz. For use as an accurate and fast-acting d.c. voltmeter this capacitor can be bypassed by setting the input-select switch to ‘d.c. coupling’.

A typical Y amplifier has relatively high input capacitance, and to reduce its loading effect on the circuit under test, a 10:1 attenuating test probe is generally used. This gives an effective load of 10 MΩ

and 12 pF, but reduces the oscilloscope’s Y-sensitivity by a factor of ten. The test probe’s compensation trimmer must be set up on a squarewave input (often available at the ’scope’s front panel) for ‘square corners’ – only then will readings at high frequencies be accurate.

The timebase section of the oscilloscope sweeps the light-spot over the tube face from left to right at constant speed, in identical fashion to that of a TV line timebase. Its sweep-speed control is calibrated in terms of time per division, and typically has a range (in conjunction with a vernier control) from 1 s/div. to 200 ns/div., often multiplied by a factor of five if required by an ‘X-expand’ switch. For examina- tion of TV field rate waveforms a typical setting would be 5 ms/div., and for line-rate waveforms 20 μs/div. The output from the sweep generator is passed to the tube’s horizontal (electrostatic) deflection system via an X amplifier. Most oscilloscopes have facilities for application of an external signal to it, for use in X-Y applications.

The sweep generator must be triggered by some Y-signal-associated pulse to display a locked waveform, and trigger circuits are built into all servicing oscilloscopes. They can be driven via a separate front panel socket (EXT TRIG) or from either Y amplifier. Switches permit selection of positive- or negative-flank triggering; trigger level; and a built-in sync separator to permit locking at line or field rate from a composite video waveform. For TV and video work external trigger- ing is recommended wherever it is possible. Some trigger circuits incorporate a variable delay (monostable type) in their path, useful for analysis of complex or transient waveforms.

The cathode ray tube is the heart of the oscilloscope, and the larger its screen the better. For best legibility a PDA (Post Deflection Acceleration) type operating at high EHT voltage (up to 15 kV) should be chosen; it gives improved performance in ‘strobe’ (short beam duty-cycle) applications.

Dual-trace ’scopes have only one electron beam. At high X-scanning speeds the two Y amplifiers are gated to alternate sweeps, and at low X-scanning speeds a beam-chopper circuit switches between the two Y amplifiers to give the effect of two separate traces; in both cases traces ‘Y1’ and ‘Y2’ can be independently positioned on the screen by separate shift controls.

Other ’scope terminals may be: sweep output; probe-calibration output; and Z (intensity modulation) input.

Frequency counter

The frequency counter is a digital instrument like the DMM, but is distinguished by its large readout length, typically 7^ or 8 digits. A precision internal reference crystal is used to time the open period of a signal gate – downstream of the gate is a pulse counter, whose accumulated count over (say) 1 second is readout on the display. With long gate periods considerable accuracy can be achieved, depending only on the accuracy of the internal crystal which may well be 2 ppm (2 in 106). The instrument can be easily checked and recalibrated if necessary by using a standard TV locked to a broadcast transmis- sion: three widely different and highly accurate standards are avail- able – field rate 50 Hz, line rate 15.625 kHz, and subcarrier frequency 4.43361875 MHz.

The main use for a frequency counter is in setting up colour-under circuits in video equipment, checking and setting SSG systems in colour cameras, and testing the operation of divider circuits. It is important to bear in mind that the digital frequency meter operates by counting zero-crossings of the waveform under test, so that where spurious components, or more than one frequency is present, erroneous or confusing readings will be obtained. A service-type counter commonly has a frequency range of 10 Hz to 200 MHz, and prescalers are available to extend this range upwards. Sensitivity is of the order of 10 mV r.m.s.

Test-pattern generator

The advance of IC technology has made possible the production of a wide range of relatively inexpensive pattern generators, ranging from battery-operated pocket types to full-facility bench models. All generate colour bars, grey-scale step wedge and a crosshatch pattern of white on black for check and adjustment of picture-tube convergence. The more elaborate types can generate coloured rasters in red, green and blue for purity checks; circles and edge castellations for tests of scanning geometry and picture centring; ‘multi- burst’ in monochrome for frequency response and focus evaluation; special patterns for adjustment of colour decoders etc. There are complete composite pattern generators available which provide a test card similar to those used by the broadcasters – one such is featured in some of the off-screen photographs later in this chapter.

Simple generators have an output at a spot frequency in the UHF band – usually around Ch. 36. Bench-type instruments will generally have r.f.-modulated outputs over the UHF broadcast bands, and often at VHF and i.f. as well. Also incorporated will be a sound facility in the form of a 1 kHz tone, a baseband (1 V p−p) CVBS video signal, and possibly line and field sync pulse outputs. The composite- test-pattern generators are particularly useful in the service workshop, where their r.f. output can be ‘spliced’ into the UHF signal distribution system for use simultaneously at all benches.

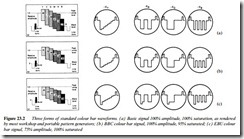

For colour bars, most generators provide 100% modulation, 100% saturation signals as used by the BBC. Other configurations are possible, however, and their effect on decoder and RGB waveforms should be borne in mind in decoder-RGB service and alignment. They are detailed in Fig. 23.2.

Vectorscope

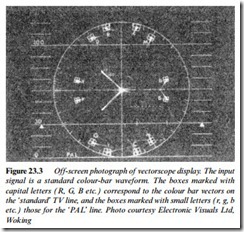

The vectorscope finds its main use in the setting-up and alignment of colour-picture sources, particularly those using analogue devices, i.e. colour TV cameras. The circular screen represents one complete cycle of the colour subcarrier frequency, with the U axis at ‘three o’clock’ and V axis at ‘12 o’clock’. At rest the light spot is at screen centre; its angle of deflection is governed by the phase of the colour signal, and its strength of deflection by the amplitude of the colour signal. These instruments have two basic inputs, a reference subcar- rier feed and the chroma signal itself.

The screen is calibrated in terms of the vector positions of the standard colour bars. A vectorscope display showing the burst and colour-bar axes for a standard signal is shown in Fig. 23.3.

Spectrum analyser

The spectrum analyser gives an amplitude versus frequency plot of the signal applied to its input, and by varying the instrument’s scanning width, the user can examine energy distribution of a modulated signal, its sidebands and harmonics. Markers are provided to identify frequency and verify bandwidth. Spectrum analysers are useful and revealing instruments for checking filter response, videorecorder f.m. modulator characteristics, camera front-end electronics, and for identifying spurious signals, but in wide-coverage form are expensive and not sufficiently often used to justify economically except in large and specialist workshops. A very useful (and less expensive) version for service and aerial/distribution work is the UHF panoramic moni- tor, which uses a varicap tuner to scan the entire broadcast band, displaying the response on the screen. Adjustment of ‘shift’ and ‘zoom’ controls permits close and useful examination of individual

broadcast carrier characteristics, as well as identification of spurious and interfering signals.

Logic probe

The logic probe takes the form of a hand-held device with an internal battery, a clip-lead for the ground connection, and a pointed prod for connection to the circuit under test. The logic indication is given as high or low, generally indicated by red and green LEDs respectively. Some types of probe have an audio output with separate tones for H and L indication. Where the probe is connected to a point carrying a pulse train the relative brightnesses of the H and L LEDs is proportional to the duty-cycle or pulse frequency at the point in question. Some probes have a third (e.g. orange-coloured) LED to indicate the presence of pulse activity – also signalled, where audio output is provided, by a warbling tone.

The logic probe is an inexpensive and convenient way of checking out operation in digital systems, especially in videorecorder syscons where parallel and single-line data is often used. Even for serial data lines and on parallel bus systems it can quickly indicate the presence or absence of pulse activity, and any ‘stuck’-high or -low lines. A great deal of diagnosis work in home computers, allied systems and peripherals can also be carried out with a logic probe.

In choosing a logic probe the important requirements are adequate overload protection; wide operating range, i.e. 5 V–15 V: wide frequency response to at least 20 MHz and ability to detect pulse trains with ‘mark’ widths down to 50 ns; compatibility with TTL, CMOS and MOS technology in microcomputers, microprocessors and the various forms of memory chip; an input impedance of 100 kΩ or more; and light but robust construction.

Logic analyser

While the logic probe is capable of indicating the status and the pres22ence of information on a data line, it is unable to give an exact picture of the pulse train regarding pulse width, pulse spacing, and timing with respect to other data lines and to the clock signal. A dual-beam oscilloscope can indicate some of these things, but a stationary read- able display is impossible with continually changing data on a serial- transmission line, and is time consuming even on a 4- or 8-wire bus carrying ‘static’ data. The need to analyse digital data fully arises surprisingly seldom except during in-depth diagnosis of computer malfunctions; in most domestic entertainment equipment an analogue meter, ’scope and logic probe are adequate for diagnosis to component level, and for diagnosis of the faults in peripheral and ‘mechanical’ components which are so often at the root of problems. For full investigation of the operation of digital circuitry a logic analyser is required. Logic analysers can operate on serial or parallel data, and consist in essence of a series of latched registers, one for each line of the data bus, and where applicable the memory and/or control buses. At the required point in the program the data is ‘frozen’ by the latch system, then the register contents are continually read out into the Y-channel of an oscilloscope for analysis. The many parallel traces are generated by a beam-switching circuit operating synchronously with the ‘scope’s sweep generator. The data words are displayed in time-coincidence. Only one input to the oscilloscope is required – all other functions are handled by the logic analyser. A photo of an LA time-domain display is given in Fig. 23.4.

Picture tube tester/reactivator

The picture-tube is the most expensive part of a TV or monitor, and since it depends on thermionic emission, it is subject to wear. An indication of its condition is given by an emission tester, which plugs

onto the tube base socket (discharge e.h.t. first) and sets up heater and gun electrode supplies to monitor beam current. In the best instruments three separate meters are used to simultaneously show the goodness of R, G and B guns for comparison. Such defects as inter-electrode short-circuits, slow warm-up and loss of vacuum are also indicated at this stage.

If low emission is indicated a reactivation process is possible. It is carried out by overrunning the tube heater for some seconds, then applying a positive voltage to the control grid. The resulting very heavy K−G current strips the oxide deposits off the cathode coating to expose a new emissive surface. This treatment is very effective, and can give a new lease of months or years to the tube’s life. A second ‘repair’ facility is provided to clear inter-electrode leaks due to conductive flakes lodging in the gun: a large capacitor is discharged across the afflicted electrodes, destroying or dispersing the conductive particle.

Signal strength meter

A useful indication of the strength of the received broadcast signal is given by an r.f. signal strength meter, which contains a standard UHF (and/or VHF) tuner, an i.f. amplifier and a meter, which generally monitors the a.g.c. control voltage required to maintain some specific level of detected video signal. Such an instrument cannot discriminate between signal and noise, and gives no indication of reflections unless it incorporates a miniature TV monitor; in the absence of this a sound detector and amplifier is usually incorporated to assist with identification of the broadcast being received. For a noise-free picture a signal level of 1 mV at the TV aerial socket is generally required, though modern TV sets give acceptable results down to below 250 μV provided the signal is reasonably free of noise.

Miscellaneous test gear

Apart from the main items so far described, the video-service jigs, tools and test cassettes covered in Chapter 18, and the variac and external power sources discussed in Chapter 11, there is a range of ‘secondary’ test equipment which is needed less often, or which is not fundamental to the servicing process.

Having to do with picture-tubes are degauss coils, with which the set, tube and magnetic shield, as well as external objects, can be demagnetised for correct purity; a microscope for checking of beam- landing accuracy in purity evaluation; and a reference light source, generally a fluorescent tube with the correct phosphor and ND filters incorporated to give a source of illuminant D at several levels for grey-scale matching. An e.h.t. meter or probe is also useful – an f.s.d. of 30 kV and impedance of >300 MΩ are typical of a practical instrument.

An insulation tester is necessary for safety checks to BEAB and BS EN60065 requirements. Be it self-powered or hand-cranked, a high applied voltage (see OEM specifications) and high resistance- reading capability are required.

A signal injector is useful for first-line and field checks on signal- dead equipment. It consists of a transistor or IC multivibrator whose basic output is in the a.f. range, but whose harmonics extend to very high frequencies. It will often help locate the point of loss of a signal – audio, video, chroma or even pre-detector, but misleading effects can result from breakthrough or radiation.

A component test-bridge can check passive components out of circuit with great accuracy, but seems to find little use in the average workshop. For testing capacitors a hand-held checker with LCD readout is available, but practice has shown that its ‘OK’ indication is not necessarily a guarantee that the capacitor will perform properly in service.