DVD capacity

The capacity of a disc is determined by the amount of data that may be stored on it in the form of pits and lands. Increasing the capacity of a DVD thus requires a corresponding increase in the density of the stored data in terms of smaller size pits, which is primarily achieved through the reduction of the dimensions of the pits. The problem however is not in the manufacture of ever smaller pits and ever closer tracks. The problem arises with the pickup head and its ability to read very tiny pits and dis- criminate between adjacent tracks. While smaller pits permit increased track density and data density along the track, it requires a corresponding smaller, more tightly focused laser read beam in order to resolve the data with the required level of accuracy. In optical storage technology, the diameter of the focused read beam is proportional to the wavelength of the read laser, and inversely proportional to the numerical aperture (NA) of the focusing lens. The NA of a lens describes it power to converge and focus the light passing through it. Therefore, smaller laser beam spot may be achieved by a combination of shorter laser wavelengths and a larger NA. In the case of DVD video, a wavelength of 650 nm (red laser) and a NA of 0.6 are specified resulting in a spot diameter of 0.54 mm compared with a wavelength of 780 nm and a NA of 0.45 and a diameter of 0.54 mm for CDs.

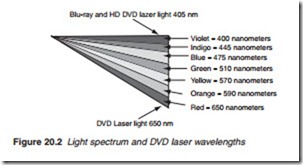

Further increase in DVD capacity was made possible by the use of blue-laser diode (LD) with a wavelength of 405 nm. The blue laser is just outside the violet of the light colour spectrum as shown in Figure 20.2 with a predominantly blue colour. The laser beam spot is reduced allowing

for even smaller pit size and closer tracks as illustrated in Figure 20.3. Based solely on the reduction of the wavelength from that of the red to the blue LD, an increase in disc data density by a factor of 2.6 is possi- ble. Coupled with the use of focusing lenses with increased NA compared to that in DVD video even greater gains in disc capacity have become possible.

In the blue-laser-based disc applications, two competing DVD disc for- mats are on offer: the HD DVD (supported by Toshiba, NEC, Sanyo and others) and the Blu-ray disc, BD (supported by Hitachi, Panasonic, Sony, Samsung and others). Both formats provide increased data-storage capac- ity (nominally 25 and 15 GB respectively) compared with the traditional DVD’s 4.7 GB nominal capacity.

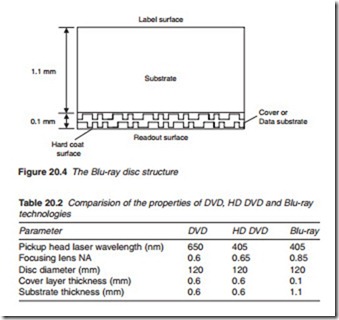

The higher capacity of the BD compared with the HD DVD is funda- mentally due to the higher NA of the focal lens. However, as the NA is increased, the quality of the optical read spot becomes more sensitive to disc tilt and variations in the cover layer thickness, causing degradation in the quality of the playback signal. For this reason, the cover layer for the Blu ray discs is reduced to 0.1 mm. While HD DVD maintains compatibil- ity with the traditional DVD having two substrate layers of 0.6 mm thick, a total of 1.2 mm, the BD has one 1.1 mm thick substrate and a 0.1 mm thick cover layer as illustrated in Figure 20.4.

A list of physical parameters of the red-laser DVD and the two blue- laser discs are listed in Table 20.2.

But while reduced cover layer thickness improves the manufacturabil- ity of the higher capacity disc, it also reduces the tolerance of the playback signal quality to the effects of dust and fingerprints compared to the con- ventional 0.6 mm cover layer design. To overcome this, a 2-nm hard coat is used at the readout surface to protect the disc from scratches and fin- gerprints. Alternatively, a cartridge may be used to protect the disc.