PROBLEMS

(Note: In questions 1-4, 6 and 8 take R 5 287 J/kg oC and γ 5 1.4.)

1. An axial-flow compressor is required to deliver 50 kg/s of air at a stagnation pressure of 500 kPa. At inlet to the first stage, the stagnation pressure is 100 kPa and the stagnation temperature is 23oC. The hub and tip diameters at this location are 0.436 and 0.728 m. At the mean radius, which is constant through all stages of the compressor, the reaction is 0.50 and the absolute air angle at stator exit is 28.8o for all stages. The speed of the rotor is 8000 rev/min. Determine the number of similar stages needed, assuming that the polytropic efficiency is 0.89 and that the axial velocity at the mean radius is constant through the stages and equal to 1.05 times the average axial velocity.

2. Derive an expression for the degree of reaction of an axial compressor stage in terms of the flow angles relative to the rotor and the flow coefficient. Data obtained from early cascade tests suggested that the limit of efficient working of an axial-flow compressor stage occurred when a relative Mach number of 0.7 on the rotor is reached; the flow coefficient is 0.5; 210 CHAPTER 5 Axial-Flow Compressors and Ducted Fans the relative flow angle at rotor outlet is 30o measured from the axial direction; the stage reaction is 50%.

Find the limiting stagnation temperature rise obtained in the first stage of an axial compressor working under these conditions and compressing air at an inlet stagnation temperature of 289 K. Assume the axial velocity is constant across the stage.

3. Each stage of an axial-flow compressor is of 0.5 reaction and has the same mean blade speed and the same flow outlet angle of 30o relative to the blades. The mean flow coefficient is constant for all stages at 0.5. At entry to the first stage, the stagnation temperature is 278 K, the stagnation pressure is 101.3 kPa, the static pressure is 87.3 kPa, and the flow area is 0.372 m2. Using compressible flow analysis determine the axial velocity and the mass flow rate. Determine also the shaft power needed to drive the compressor when there are six stages and the mechanical efficiency is 0.99.

4. A 16-stage axial-flow compressor is to have a pressure ratio of 6.3. Tests have shown that a stage total-to-total efficiency of 0.9 can be obtained for each of the first six stages and 0.89 for each of the remaining 10 stages. Assuming constant work done in each stage and similar stages find the compressor overall total-to-total efficiency. For a mass flow rate of 40 kg/s determine the power required by the compressor. Assume an inlet total temperature of 288 K.

5. At a particular operating condition an axial-flow compressor has a reaction of 0.6, a flow coefficient of 0.5, and a stage loading, defined as Δh0/U2 of 0.35. If the flow exit angles for each blade row may be assumed to remain unchanged when the mass flow is throttled, determine the reaction of the stage and the stage loading when the air flow is reduced by 10% at constant blade speed. Sketch the velocity triangles for the two conditions.

Comment upon the likely behavior of the flow when further reductions in air mass flow are made.

6. A high-pressure axial compressor for a jet engine rotates at 15,000 rpm with an overall stagnation pressure ratio of 8.5. The mass flow rate of air through the compressor is 16 kg/s and the stagnation conditions at inlet are 200 kPa and 450 K. The polytropic efficiency is 91%.

a. If the mean radius is 0.24 m and this is constant throughout the compressor, calculate the total-to-total isentropic efficiency of the compressor and show that, for the stage loading to be less than 0.4 in all stages, eight stages are required.

b. The compressor is designed with repeating stages and zero inlet swirl. If the inlet axial Mach number is 0.52, calculate the mean flow coefficient and sketch the velocity triangles for one stage. Show that the blade height at exit from the compressor is about 7.8 mm.

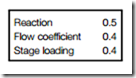

7. At the design operating point, the stage characteristics of a low-speed compressor are as follows:

Assuming constant axial velocity across the stage and equal absolute velocities at inlet and outlet, determine the exit relative flow angle from the rotor and the exit absolute flow angle from the stator. At an off-design condition, the flow coefficient is reduced to 0.3. Assuming that the deviation from the rotor and stator are unchanged from the design condition, determine the new stage loading. If instead, the deviations from both the rotor and the stator increase by 3o, determine the new stage loading at the off-design condition.

8. Air enters an axial-flow compressor with a stagnation pressure and temperature of 100 kPa and 293 K, leaving at a stagnation pressure of 600 kPa. The hub and tip diameters at entry to the first stage are 0.3 and 0.5 m. The flow Mach number after the inlet guide vanes is 0.7 at the mean diameter (0.4 m). At this diameter, which can be assumed constant for all the compressor stages, the reaction is 50%, the axial velocity to mean blade speed ratio is 0.6, and the absolute flow angle is 30o at the exit from all stators. The type of blading used for this compressor is designated “free vortex” and the axial velocity is constant for each stage. Assuming isentropic flow through the inlet guide vanes and a small stage efficiency of 0.88, determine

a. the air velocity at exit from the inlet guide vanes at the mean radius;

b. the air mass flow and rotational speed of the compressor;

c. the specific work done in each stage;

d. the overall efficiency of the compressor;

e. the number of compressor stages required and the power needed to drive the compressor;

f. consider the implications of rounding the number of stages to an integer value if the pressure ratio must be maintained at 6 for the same values of blade speed and flow coefficient.

9. The compressor represented in Figure 5.8 has a mean blade speed of 350 m/s when operating at its design point. At the design point, all 10 stages of the compressor can be treated as repeating stages with a flow coefficient of 0.5 and a reaction of 0.6.

Take the inlet stagnation temperature to be 300 K, γ 5 1.4 and Cp 5 1005 J/kg K.

a. Find the stage loading and the interstage swirl angle that applies to all the stages at the design point.

b. When operating on the working line at 90% speed, estimate the flow coefficients for the first stage and the last stage (for the last stage assume that the nondimensional mass flow is equal to that at compressor exit). Assuming the interstage swirl angles are unchanged from the design point, find the rotor relative inlet angles for the first and last stages at this condition. Hence, determine the change in incidence from the design point, for the last stage rotor and the first stage rotor.

c. The swirl angle at inlet to the first stage can be adjusted by a variable guide vane. Find the inlet swirl angle required at 90% speed to give the same incidence onto the first stage rotor as at the design point.

10. A transonic fan used in a jet engine operates with axial flow at inlet and a flow coefficient of 0.5. The rotor inlet relative Mach number is 1.6 and this is equal to the Mach number just upstream of the passage normal shock wave. The relative flow angles at inlet and exit from the rotor are equal and there is no change in flow radius.

a. Using Eqs (4.21) and (5.28a), determine the rotor loss coefficient if all of the loss is shock loss. Check this using Figure 5.12.

b. The following equation relates the relative Mach number downstream of the passage shock wave to the upstream relative Mach number:

Referring to the velocity triangles in Figure 5.11, use the above equation to determine the stage loading of the fan stage.

c. Show that the stagnation temperature ratio across the fan stage can be written as:

By combining the above result with the rotor loss coefficient, determine the rotor alone total-to-total efficiency and the stagnation pressure ratio across the rotor.

Note: In the following problems on low-speed axial-flow fans the medium is air for which the density is taken to be 1.2 kg/m3.

11. a. The volume flow rate through an axial-flow fan fitted with inlet guide vanes is 2.5 m3/s and the rotational speed of the rotor is 2604 rev/min. The rotor blade tip radius is 23 cm and the root radius is 10 cm. Given that the stage static pressure increase is 325 Pa and the blade element efficiency is 0.80, determine the angle of the flow leaving the guide vanes at the tip, mean, and root radii.

b. A diffuser is fitted at exit to the fan with an area ratio of 2.5 and an effectiveness of 0.82.

Determine the overall increase in static pressure and the air velocity at diffuser exit.

12. The rotational speed of a four-bladed axial-flow fan is 2900 rev/min. At the mean radius of 16.5 cm, the rotor blades operate at CL 5 0.8 with CD 5 0.045. The inlet guide vanes produce a flow angle of 20o to the axial direction and the axial velocity through the stage is constant at 20 m/s. For the mean radius, determine

a. the rotor relative flow angles;

b. the stage efficiency;

c. the rotor static pressure increase;

d. the size of the blade chord needed for this duty.

13. A diffuser, fitted to the axial fan in the previous problem, has an efficiency of 70% and an area ratio of 2.4. Assuming that the flow at entry to the diffuser is uniform and axial in direction, and the losses in the entry section and the guide vanes are negligible, determine

a. the static pressure rise and the pressure recovery factor of the diffuser;

b. the loss in total pressure in the diffuser;

c. the overall efficiency of the fan and diffuser.

Related posts:

Incoming search terms:

- axial flow compressor solved problems

- axial flow compressor problems

- problems on axial flow compressor

- solved problems on axial flow compressor

- solved numericals on axial compressors

- sixteen stage axial flow compressor problem

- axial flow turbine operating with an overall stagnation pressure solved problems

- axial flow compressors numericals

- axial compressor required to deliver 50kg/s of air at a

- A 16- stage axial flow compressor is to have a pressure ratio 6 3

- A 16-stage axial flow compressor is to have a pressure of 6 3

- problems on axial flow compressors

- an axial compressor solved problems

- problems on axial

- polytropic efficiency of axial flow compressor with solve example

- numericals on axial flow compressors

- https://yandex ru/clck/jsredir?from=yandex ru;search;web;;&text=&etext=1839 tEkMGkbyTvot4HK1D19QMpXKlsT0lmZhGeIwnfXRLV6SuH8VkWqnmCD18LshUFAKZFlJafGeYM-cc9yp4iatgw c27d3270a945027c04b8c08fb6eda7cf8458ad61&uuid=&state=_BLhILn4SxNIvvL0W45KSic

- https://yandex ru/clck/jsredir?from=yandex ru;search;web;;&text=&etext=1834 W62gPXWBpec9Nuxjmlj3txDWyORQSAZFxmR-TLTPVQklh9QpwAVVk5lnLJn1s1r4AcBKbKk_EzsgjyNKpDFOCg 474cc5b5d0903cf772ea1d56354b6a24cf9c8a74&uuid=&state=_BLhILn4SxNIvvL0W45KSic

- an axial flow compreeor problems

- an axial flow compressor is required to deliver 50 kg/s of air at a stagnation pressure of 5 bar at the inlet to the first stage the stagnation pressure is 1 bar and the temperature is 300k the hub and tip diameter at this location are 0 436 m and 0 728 m

- Axial compressor numericals

- 1 An axial flow air compressor has an overall compression ratio of six The inlet conditions are Tor 300 K and Por= 100 kPa The degree of reaction is 0 5 and the fluid angle at the stator exit is 30 The stage polytropic efficiency is 85o and the axial velo