A unified correlation for slip factor

It will have been noticed for the preceding correlations of slip factor that once the geometry of an impeller is defined (i.e., the exit blade angle, the number of blades and (possibly) the inlet blade angle), then the slip factor is firmly fixed. However, a new, unified slip factor has been defined by Qiu et al. (2011) which is applicable to axial, radial, and mixed flow impellers and, importantly, takes into account the effect of the flow coefficient. This is a most interesting and significant development of slip factor theory. According to the paper’s authors, slip factor is affected by the impeller rotation as well as by the blade turning rate at the point of impeller discharge.

For an axial impeller (i.e., a compressor blade row), there is no radial effect and the resulting slip factor is comparable to the deviation rule of Howell, Carter, and others (see Eqs (3.34) and (3.35)). However, for many radial impellers it turns out that the blade turning term is significant and is actually the key factor that dominates the variation of the slip factor at off-design conditions.

Eck (1973) extended the theory originally advanced by Stodola in which it was asserted that it

was the relative eddy which caused the slip in centrifugal impellers. Velocity differences are created in the blade passages so that the velocity on the pressure side of a blade is less than that on the suction side. In Figures 7.13 and 7.16, the pressure side of the passage is, of course, on the right. The relative eddy is imagined to be circular in shape with a diameter d, (shown as AC in Figure 7.16) rotating as a solid body with an angular velocity Ω. The slip velocity is then deter- mined from,

where the angular velocity in Stodola’s flow model is the same as the wheel speed but in the opposite direction.

3The word “unified” refers to the intention of the authors to bring into one theory all varieties of compressor. It is not the intention of the present authors to verify the wider aspects of the paper (i.e., application to axial and mixed flow compressors) only to centrifugal compressors.

Inside the impeller passage, the flow is loaded by the Coriolis force, the centrifugal force, and the blade turning force. According to Qiu, these forces vanish when the flow reaches the line AC with the result that the flow deviates from its expected path. This is the crucial point of Qiu’s argument.

The next step is to quantify the blade loading up to AC so that the right-hand side of Eq. (7.27) can be evaluated.

Qiu assumed that the velocity difference between D and A is small so that the blade loading at AC can be determined (approximately) by the loading on the arc DC. Following fairly recent work by Johnson (1986) and Cumpsty (1989), Qiu found that the loading on the arc DC could be expressed by the following equation:

is the decrement due to any variations of passage width and density.

Qiu stated that the radical term in Eq. (7.32c) will be very small compared with the other terms and that its contribution to the slip factor would be minimal. Therefore, this last term is disregarded in all the following calculations.

Comparison of the new slip factor theory with experimental results Method of Calculating the Shape Factor F

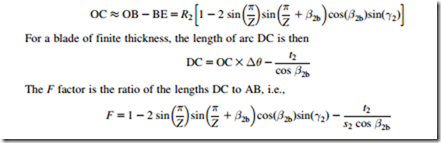

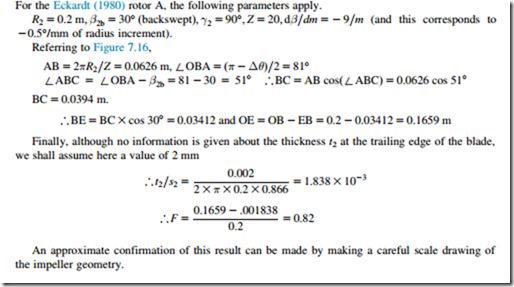

Referring to Figure 7.16, the line AC is drawn from point A and is perpendicular to the adjacent blade. The line AC is referred to as the exit throat. The object of the following method is to calcu- late the length of the arc DC.

The angle between two adjacent blades is Δθ 5 2π=Z, where Z is the number of blades.

The chord AB can now be calculated as

The presence of the angle γ2 is because the whole calculation is projected onto the radial plane so as to determine the reduction in radius. Therefore, the radius of the arc DC is

Illustrative exercise (determining a value for F)

Results

Values of the slip factor calculated by Qiu for the Eckardt rotor A are shown in Figure 7.14 as a function of the exit flow coefficient Φ2. By way of contrast, the results determined using the Stodola and Wiesner formulae are shown. It is clear that the current model matched the experimental values measured for this rotor closely at all speeds whereas the Stodola and Wiesner did not come close. This seems to be a remarkable achievement by the authors and they deserve everyone’s congratulations! It should be mentioned that Qiu and his colleagues were supported in their conclusions by a vast number of confirmatory tests on many other types of rotors and pumps.

Qiu expressed the view that the negative blade turning rate was responsible for the upward trend of the slip factor with the exit flow coefficient. Finally, Qiu emphasized how all the data points for all four speeds closely followed a single curve. This observation confirmed that the slip factor correlated with a single parameter—the exit flow coefficient.

It may have been noticed from the references at the end of this chapter that some attempts have been made by various authors to include the variation of the flow rate in their predictions of the slip factor.